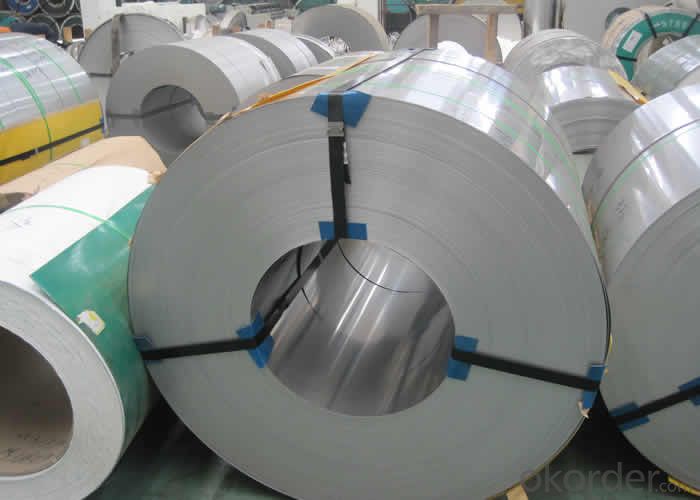

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK: 2.3/2.5/3.0/4.0mm

Width: 485/510/550/610/1010/1240mm

Face: No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%

Modulus Of Elasticity:29,000,000 Psi

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q:Can stainless steel strips be used in medical implant manufacturing?

- Yes, stainless steel strips can be used in medical implant manufacturing. Stainless steel is a commonly used material in the medical field due to its excellent corrosion resistance, high strength, and biocompatibility. It is often used for implants such as orthopedic devices, cardiovascular stents, and dental implants.

- Q:Can stainless steel strips be used for food storage containers?

- Yes, stainless steel strips can be used for food storage containers. Stainless steel is a popular choice for food storage containers due to its durability, resistance to corrosion, and its ability to prevent the transfer of odors and flavors. It is a safe and hygienic material that does not react with acidic or alkaline foods, making it suitable for storing a wide range of food items.

- Q:Can stainless steel strips be used in transportation applications?

- Yes, stainless steel strips can be used in transportation applications. Stainless steel is known for its strength, durability, and resistance to corrosion, making it suitable for various components in transportation such as vehicle frames, exhaust systems, and structural parts.

- Q:What are the common surface defects in stainless steel strips?

- Some common surface defects in stainless steel strips include scratches, pits, and surface roughness. Scratches can occur during handling, transportation, or processing of the strips. Pits are small depressions or cavities on the surface, often caused by corrosion or impurities. Surface roughness can result from improper grinding, polishing, or finishing processes. Other defects may include stains, discoloration, or uneven coating. It is important to carefully inspect stainless steel strips for these defects as they can affect the appearance, performance, and durability of the material.

- Q:Can stainless steel strips be used in the medical implants?

- Medical implants can indeed utilize stainless steel strips. This material boasts durability and resistance to corrosion, rendering it appropriate for deployment in medical devices and implants. Commonly, it finds extensive application in orthopedic implants like bone plates, screws, and wires, alongside cardiovascular stents and dental implants. Stainless steel also possesses exceptional biocompatibility, ensuring compatibility with the human body and averting adverse reactions or toxicity. Furthermore, it facilitates straightforward sterilization, a vital aspect for medical implants to prevent infections. Consequently, stainless steel strips constitute a dependable and widely employed substance in the fabrication of medical implants.

- Q:What are the different types of perforation for stainless steel strips?

- There are several different types of perforation for stainless steel strips, including round, square, slotted, and decorative patterns. Each type of perforation serves a specific purpose and can be chosen based on the desired aesthetic, functionality, and application requirements.

- Q:Can stainless steel strips be used in renewable energy applications?

- Yes, stainless steel strips can be used in renewable energy applications. Stainless steel is a versatile and durable material that offers several benefits for renewable energy systems. One of the main advantages of stainless steel is its corrosion resistance, which makes it ideal for outdoor and wet environments. In renewable energy applications such as solar and wind power systems, stainless steel strips can be used to construct frames, supports, and brackets that withstand exposure to various weather conditions over the long term. Furthermore, stainless steel has excellent mechanical properties, including high strength and ductility. This allows it to withstand heavy loads and vibrations, making it suitable for applications such as wind turbine components, solar panel mounting systems, and hydroelectric power infrastructure. Stainless steel is also highly heat resistant, which is crucial in many renewable energy applications. For example, it can be used in concentrated solar power systems, where mirrors focus sunlight onto a receiver to generate heat for electricity production. In this case, stainless steel strips can be used to construct the receiver components, which need to withstand high temperatures without deforming or corroding. Additionally, stainless steel is a sustainable material itself, as it is 100% recyclable. This aligns with the principles of renewable energy and the overall goal of reducing environmental impact. In summary, stainless steel strips can be effectively utilized in renewable energy applications due to their corrosion resistance, mechanical strength, heat resistance, and recyclability. These properties make stainless steel a reliable and sustainable choice for constructing various components in renewable energy systems.

- Q:Are stainless steel strips resistant to nitric acid?

- Stainless steel strips are typically resistant to nitric acid. Renowned for its exceptional corrosion resistance, stainless steel shows commendable resilience against various acids, including nitric acid. Nevertheless, the degree of resistance may fluctuate based on the particular grade or alloy of stainless steel employed, alongside the nitric acid's concentration and temperature. It is highly advisable to seek guidance from the stainless steel manufacturer or supplier for precise details regarding their products' resistance to nitric acid in your specific application.

- Q:Are stainless steel strips suitable for HVAC applications?

- Indeed, HVAC (heating, ventilation, and air conditioning) applications find stainless steel strips to be suitable. Stainless steel, as a versatile and durable material, exhibits exceptional resistance to corrosion, heat, and pressure. These attributes render it highly suitable for deployment in demanding environments commonly encountered in HVAC systems. In HVAC applications, stainless steel strips find widespread usage for a variety of purposes. Notably, they are frequently employed in the fabrication of air ducts, which serve as vital components for distributing heated or cooled air throughout a structure. Stainless steel strips provide the requisite strength, rigidity, and resistance to endure the pressure and temperature fluctuations inherent in ductwork. Moreover, stainless steel strips also play a pivotal role in HVAC systems by facilitating the production of heat exchangers. These components are indispensable for transferring thermal energy between fluids. The corrosion resistance of stainless steel ensures that heat exchangers can withstand exposure to diverse liquids and gases without succumbing to degradation over time. Furthermore, HVAC applications favor stainless steel strips due to their hygienic properties. They are easily cleaned and maintained, while being unfriendly to the growth of bacteria or mold. Consequently, they prove to be an ideal choice for usage in environments where air quality holds paramount importance, such as hospitals and laboratories. In conclusion, stainless steel strips emerge as an ideal choice for HVAC applications. Their exceptional corrosion resistance, durability, and hygienic properties establish them as a dependable option for manufacturing air ducts, heat exchangers, and other crucial components employed in HVAC systems.

- Q:What are the common weight tolerances for stainless steel strips?

- The common weight tolerances for stainless steel strips can vary depending on the specific grade and thickness of the strip. However, typical weight tolerances for stainless steel strips range from +/- 5% to +/- 10% of the specified weight.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords