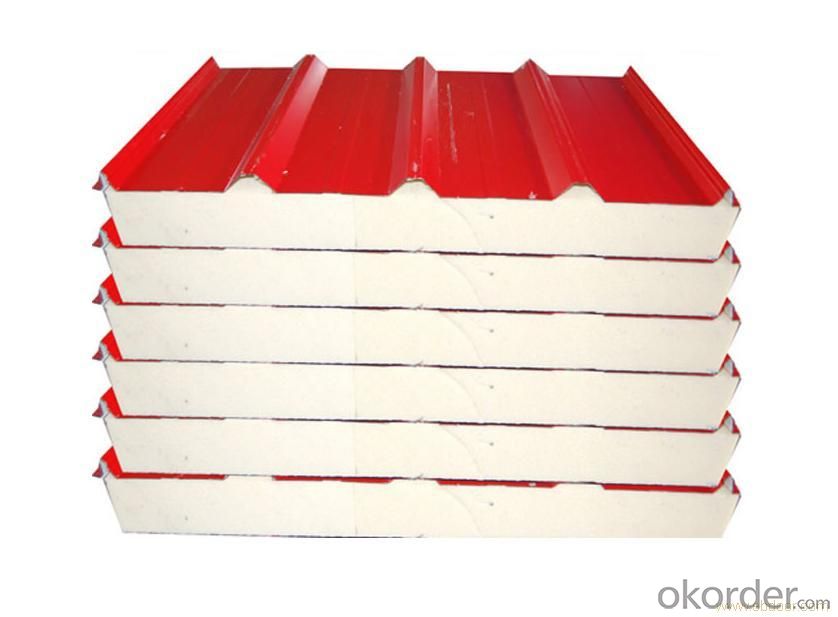

EPS Roof Sandwich Panel/Polystyrene Foam Sandwich Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 25000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panels are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

Packaging & Delivery

Packaging Details:covered by LDPE Guard Film and put into the container directly or as required

Delivery Detail:25 working days after receiving 30% deposit

Specifications

1) Sandwich Roof Panel

2) Light Weight,Sound Insulation

3) Heat Insulation,Preservation

4)Fire,Water Proof

5) Fast, Easy

Size

UP/LOWER STEEL SHEET:

Thickness: 0.2mm-0.8mm

Width: 960mm

Material: color-coated panel/zinc plate,hot galvanized plate

Surface: LDPE Guard Film

EPS BEADS:

Density:80kg--120kg/m3

Thickness: 40mm-50mm-75mm-100mm-120mm-150mm-170mm

Length: considering the transportation, it is better don't beyond 11.8 meters.

Rockwool Sandwich Panel Introduce:

Thickness:50mm-150mm

Width:950mm-1150mm

Steel Thickness:0.2mm-0.80mm

rockwool sandwich panel:

Features of rockwool sandwich panel as follows:

- Q:Are steel sheets suitable for construction applications?

- Steel sheets are an ideal choice for construction applications due to their exceptional qualities. Renowned for their strength, durability, and versatility, steel is widely favored in the construction industry. Steel sheets find extensive use in various areas, including roofing, flooring, wall panels, structural frames, and cladding. They possess remarkable load-bearing capacity, enabling the construction of substantial and robust structures. Furthermore, steel sheets offer fire resistance, thereby enhancing the safety of buildings. Additionally, they are resilient against pests, rot, and corrosion, ensuring a prolonged lifespan for constructions. Moreover, steel sheets can be effortlessly fabricated and tailored to meet diverse construction requirements, making them a cost-effective and efficient option. In summary, steel sheets are highly suitable for construction applications due to their strength, durability, versatility, and various other advantageous properties.

- Q:How do steel sheets handle weathering?

- Steel sheets have been designed to effectively handle weathering. Typically, they are coated with a protective layer, such as zinc or a combination of zinc and aluminum, which creates a barrier against moisture and other environmental elements. This coating, known as galvanization, prevents the steel from corroding or rusting when exposed to rain, snow, and other forms of precipitation. Aside from the protective coating, various chemical processes are used to enhance the steel sheets' resistance to weathering. These processes may involve applying primers, paints, or sealants that further shield the steel from moisture, UV radiation, and extreme temperature fluctuations. Furthermore, the composition of steel itself contributes to its ability to withstand weathering. Steel is primarily comprised of iron, carbon, and other elements, forming an alloy that provides inherent strength and durability. This structural integrity enables steel sheets to resist deformation, cracking, or warping caused by weather-related stresses. However, it is important to acknowledge that even the most well-protected steel sheets may gradually experience some degree of weathering over time. Harsh environmental conditions can gradually degrade the protective coating, resulting in the formation of small areas of rust or corrosion. Regular maintenance, such as cleaning, inspecting, and reapplying protective coatings, can help extend the lifespan of steel sheets and preserve their resistance to weathering.

- Q:Do the steel sheets have any specific fire ratings?

- Yes, steel sheets can have specific fire ratings. Fire ratings for steel sheets are determined by their ability to withstand fire and prevent the spread of flames. These ratings are typically classified based on the amount of time the steel sheets can resist fire before it penetrates or collapses. Common fire rating classifications for steel sheets include 30 minutes, 60 minutes, 90 minutes, and 120 minutes. These ratings are determined through rigorous testing methods that evaluate the steel sheets' performance under fire conditions, such as exposure to high temperatures and flames. It is important to consult the manufacturer or supplier for specific fire ratings of the steel sheets to ensure they meet the required safety standards for your intended application.

- Q:Can steel sheets be used for elevator or escalator components?

- Yes, steel sheets can be used for elevator or escalator components. Steel is a durable and strong material that can withstand the weight and stress associated with elevator and escalator operations. It is commonly used for constructing various components such as frames, doors, panels, and supports in these systems.

- Q:Can steel sheets be used for manufacturing security doors?

- Indeed, security doors can be manufactured using steel sheets. Steel, being a robust and long-lasting material, offers exceptional security and safeguarding. It possesses the ability to withstand forced entry attempts and provides resistance against break-ins. Due to their remarkable tensile strength, steel sheets are frequently employed in the construction of security doors as they are difficult to bend or break. Moreover, steel doors can be further reinforced with various additional features, including multiple locks, deadbolts, and security bars, to enhance their security capabilities. All in all, steel sheets serve as a dependable option for the production of security doors.

- Q:What are the different packaging options for steel sheets?

- Some of the different packaging options for steel sheets include bundles, coils, pallets, and crates. Bundles are typically used for smaller sheets and consist of multiple sheets stacked together and secured with metal straps. Coils are used for larger sheets and are wound into a cylindrical shape. Pallets are commonly used for transportation and storage, where steel sheets are placed on top of a wooden or plastic pallet and secured with straps or stretch film. Crates are wooden or metal containers that provide additional protection for steel sheets during transportation and can be customized to fit specific sheet sizes and quantities.

- Q:Can steel sheets be used for electrical grounding purposes?

- Yes, steel sheets can be used for electrical grounding purposes. Steel is a good conductor of electricity, which makes it suitable for grounding applications. When properly connected to an electrical system, steel sheets can provide an effective path for the dissipation of electrical charges and prevention of electrical shock hazards. However, it is important to ensure that the steel sheets are adequately bonded and connected to the grounding system in order to create a low-resistance path for fault currents. Additionally, factors such as the thickness and surface area of the steel sheets should be considered to ensure they meet the requirements for effective grounding.

- Q:What is the maximum width of steel sheets?

- The maximum width of steel sheets can vary depending on the manufacturing process and specific requirements, but it is typically around 2.5 meters or 8 feet.

- Q:Are steel sheets suitable for high-temperature applications?

- Yes, steel sheets are suitable for high-temperature applications due to their high melting point, excellent strength, and heat resistance properties. Steel sheets can withstand extreme temperatures without losing their structural integrity, making them ideal for applications such as furnace linings, heat exchangers, and exhaust systems.

- Q:How can the white steel plate be bright and cleaned?

- White steel plate has higher plasticity, toughness and mechanical strength, acid, alkaline gas, solution and other media corrosion. It is an alloy steel which is not easily rusted, but it is not absolutely rusty.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPS Roof Sandwich Panel/Polystyrene Foam Sandwich Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 25000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords