Unequal Angle Bars Hot sales&Free Sample Stainless Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | stainless steel unequal angle bars standard seaworthy packing(plastic&wooden) or according to the customer's requests |

| Delivery Detail: | stainless steel unequal angle bars delivey time is 15-25 days |

Specifications

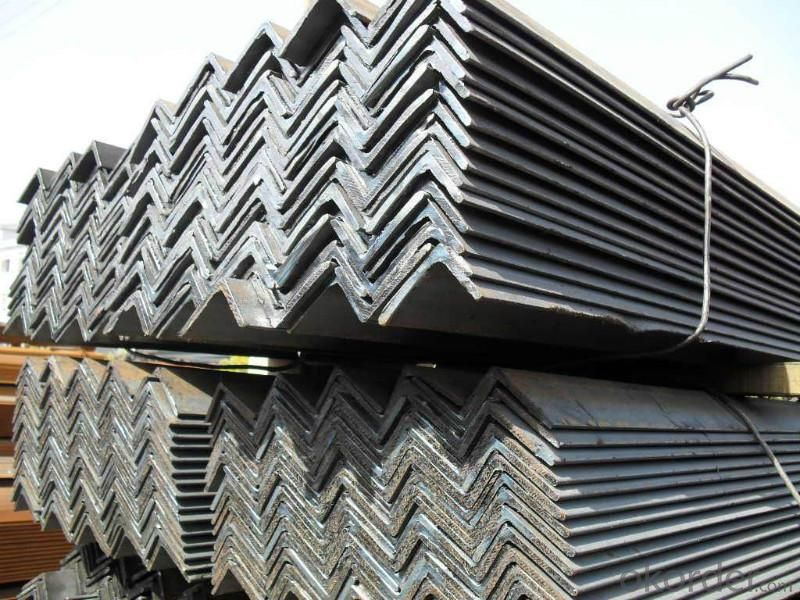

stainless steel unequal angle bars

1.Plentiful storage and short delivery time

2.direct factory sales

3.Reasonable price

stainless steel unequal angle bar

Product Description

basic information

Standard | AISI,ASTM,DIN,GB,JIS |

Material | 201,202,301,304,304L,316,316L,321,410,420,430etc |

Surface | bright , polished , sand blasting ,Cold drawn , hot rolled, etc |

Diameter | 2.5#,3#,4#,5#,6#,7#,7.5#,8#,10# |

Length | 6mter or as your requirement |

Packing | seaworthy packing(plastic & wooden) or according to the customer's requests |

MOQ | 0.5TON |

Delivery time | 15-25 days, as quanlity |

Application | These products are widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, hoisting, ship industrial furnace, container frame and warehouse and Other fields. |

Contacts | If you are interested in our product, please feel free to contact us. Welcome your requires and hope we can establish friendly and long cooperative relations |

product picture

bright surface

why choose us?

1.In each manufacturing process,we arrange a technician in charge of inspection to make sure the final product completely qualified.

2.We take more machanized operations to decrease human labor cost.

3.We have an experienced term available to serve you,and supply you all you want.

4.In case of any problems occurs to our products you receive,we will redeliver them to you,or refund your payment,or solve it as the method we negotiate.

- Q:Can steel angles be used for support structures in telecommunications installations?

- Yes, steel angles can be used for support structures in telecommunications installations. Steel angles provide strength, stability, and durability, making them suitable for supporting heavy equipment such as antennas, cables, and other telecommunications infrastructure.

- Q:How do steel angles contribute to the sustainability of a project?

- Steel angles contribute to the sustainability of a project in several ways. Firstly, they are made from recycled steel, reducing the demand for new raw materials and promoting a circular economy. Secondly, steel angles have a high strength-to-weight ratio, allowing for lighter and more efficient structural designs, which in turn reduces the amount of steel required and minimizes the carbon footprint of the project. Lastly, steel angles are durable, resistant to corrosion, and have a long lifespan, ensuring the longevity and sustainability of the structure they support.

- Q:What is the difference between hot-rolled and cold-rolled steel angles?

- Two distinct methods, hot-rolling and cold-rolling, are employed in the production of steel angles, resulting in varying characteristics. Hot-rolling involves heating a steel billet or ingot to a high temperature and subsequently passing it through a series of rollers. This process allows for the metal to be shaped and formed while it retains its malleability and pliability. Consequently, hot-rolled steel angles possess a coarser surface finish and less precise dimensions when compared to their cold-rolled counterparts. However, their strength and durability are generally superior, rendering them appropriate for structural applications necessitating high strength and load-bearing capacity. Conversely, cold-rolling entails passing hot-rolled steel through a sequence of rollers at room temperature. This procedure not only refines the dimensions and surface finish of the steel angles but also enhances their strength and hardness. Cold-rolled angles exhibit a smoother surface finish and more accurate dimensions, making them ideal for applications requiring precise fitting or a polished appearance. They are commonly employed in architectural and decorative endeavors, as well as in industries where aesthetics and precision are paramount. To summarize, the primary disparities between hot-rolled and cold-rolled steel angles lie in their manufacturing processes, surface finishes, dimensional accuracy, and applications. Hot-rolled angles are stronger and rougher, rendering them suitable for structural purposes, whereas cold-rolled angles possess a smoother finish and precise dimensions, making them more appropriate for decorative and architectural applications.

- Q:Can steel angles be used for foundation supports?

- Indeed, foundation supports can utilize steel angles. In construction endeavors, steel angles are frequently employed to furnish structural support and stability. Possessing the capacity to endure substantial burdens and offer longevity, steel angles prove themselves ideal for foundation supports. Furthermore, steel angles can be effortlessly linked to other structural elements, like beams or columns, to establish a steadfast foundation system. Moreover, steel angles can be tailored and manufactured to precise measurements and proportions, guaranteeing they conform to the unique prerequisites of the foundation design.

- Q:Can steel angles be used for manufacturing outdoor benches?

- Yes, steel angles can be used for manufacturing outdoor benches. Steel angles provide strength, durability, and stability, making them suitable for outdoor use. Additionally, steel angles can withstand weather elements such as rain, sun exposure, and temperature changes, ensuring the longevity of the outdoor benches.

- Q:What is hot dip galvanized steel angle?

- It's angle iron. Hot galvanizing is a way of preserving it

- Q:Can steel angles be used for building frames?

- Yes, steel angles can be used for building frames. They are often used as structural elements in construction due to their strength and versatility. Steel angles provide stability and support to building frames, making them a popular choice in the construction industry.

- Q:Can steel angles be used for foundation reinforcement?

- Yes, steel angles can be used for foundation reinforcement. Steel angles are commonly used in construction projects for their strength and durability. When properly installed and secured, steel angles can provide additional support and stability to a foundation, helping to prevent cracks, settlement, and other structural issues.

- Q:How do you protect steel angles from moisture?

- There are several measures you can take to protect steel angles from moisture: 1. Applying a protective coating is a highly effective method. By using paint or primer, you create a barrier that prevents direct contact between the steel and moisture, thus avoiding potential corrosion. 2. Another option is galvanization. This involves coating the steel angles with a layer of zinc, which provides excellent protection against moisture. This process creates a sacrificial layer that corrodes before the steel, extending its lifespan. 3. Implementing proper drainage systems is crucial. By installing gutters, downspouts, or using sloping surfaces, you can ensure water does not accumulate around the steel angles, preventing prolonged exposure to moisture. 4. Regular inspection and maintenance are essential. Keep an eye out for signs of moisture buildup, rust, or damage on the steel angles. Take immediate action by cleaning, repairing, or applying additional protective coatings to prevent moisture from seeping in. 5. Consider using moisture-absorbing materials such as desiccants or silica gel packs in the vicinity of steel angles. These materials help reduce humidity levels and prevent moisture buildup. 6. If the steel angles are located in an enclosed space, controlling humidity levels is crucial. Ensure proper ventilation and use dehumidifiers or fans to reduce moisture and prevent condensation on the steel surfaces. By following these preventive measures, you can effectively safeguard steel angles from moisture, increasing their lifespan and preventing corrosion.

- Q:How are steel angles protected against atmospheric corrosion?

- Steel angles are protected against atmospheric corrosion through a variety of methods. One common method is by applying a protective coating, such as paint, to the surface of the steel angles. This coating acts as a barrier between the steel and the surrounding atmosphere, preventing the steel from coming into direct contact with moisture or oxygen, which are the main contributors to corrosion. Another method of protection is through galvanization. Galvanization involves coating the steel angles with a layer of zinc, either through hot-dip galvanization or electroplating. The zinc acts as a sacrificial layer, corroding in place of the steel. This sacrificial corrosion process helps to protect the steel angles from atmospheric corrosion. In addition to coatings, steel angles can also be protected through the use of inhibitors. Inhibitors are substances that are added to the surrounding environment or applied directly to the steel surface to slow down or prevent corrosion. These inhibitors work by either forming a protective film on the steel surface or by altering the chemical environment to make it less corrosive. Regular maintenance and inspection are also essential in protecting steel angles against atmospheric corrosion. This includes cleaning the surface of the steel angles to remove any dirt or debris that may trap moisture and accelerate corrosion. It is also important to promptly repair any damaged or deteriorated coatings to ensure continued protection against corrosion. Overall, a combination of protective coatings, galvanization, inhibitors, and regular maintenance is necessary to effectively protect steel angles against atmospheric corrosion and extend their lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unequal Angle Bars Hot sales&Free Sample Stainless Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords