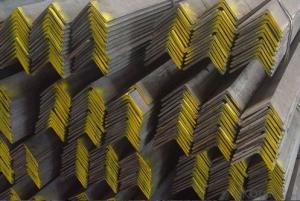

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Hot Rolled Equal and Unequal perforated Steel Angle Iron

1.Standard: GB,ASTM,JIS

2.Steel Grade:Q195-Q420

3.Length: 5.8-12mm

Hot Rolled Unequal perforated Steel Angle Iron

| ||

Thickness | 12mm | |

3mm-25mm | 20mm-200mm | |

Length

| 5.8-12M , according to customers' requirements | |

Standard

| GB,JIS,ASTM,EN,DIN | |

Material

| 304 304L 316 321 | |

Type | Equal and unequal | |

Usage

| constructions,communication towers and so on. | |

Certification

| ISO9001,ISO9002,API | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:How do steel angles compare to other structural materials?

- Steel angles are a popular choice in the construction industry due to their versatility and strength. Compared to other structural materials, such as wood or aluminum, steel angles offer several advantages. Firstly, steel angles have superior strength and load-bearing capacity. They can support heavy loads and provide structural stability, making them ideal for use in buildings, bridges, and other infrastructure projects. Steel angles also have a high resistance to bending and twisting, ensuring durability and longevity in various applications. Additionally, steel angles are highly versatile. They can be easily customized and fabricated into different shapes and sizes, allowing for precise and efficient construction. This flexibility enables designers and engineers to create complex structures and achieve specific architectural requirements. Steel angles also provide excellent fire resistance compared to materials like wood. Steel is non-combustible, meaning it does not fuel the spread of fire, making it a safer option in buildings and structures. Moreover, steel angles have a high recyclability rate, making them environmentally friendly. Steel is one of the most recycled materials in the world, and using steel angles in construction contributes to sustainable building practices and reduces the demand for new raw materials. However, it is worth mentioning that steel angles can be more expensive than some other materials, such as wood or aluminum. Additionally, steel requires proper surface treatment and corrosion protection to prevent rusting and maintain its structural integrity. Overall, steel angles offer numerous advantages over other structural materials, including superior strength, versatility, fire resistance, and recyclability. These qualities make them a preferred choice in many construction projects, where durability, efficiency, and safety are paramount.

- Q:Can steel angles be used for equipment racks?

- Yes, steel angles can be used for equipment racks. Steel angles provide structural support and stability, making them suitable for holding heavy equipment and ensuring durability.

- Q:Can steel angles be used for acoustic isolation or noise barriers?

- While steel angles have the potential to be used for acoustic isolation or noise barriers, their effectiveness may not be on par with materials specifically engineered for this purpose. Sound waves can be somewhat reduced by steel angles through reflection and absorption, but this depends on factors like steel thickness, density, and barrier design. It's worth noting that steel angles are not typically intended for soundproofing, so relying solely on them may not yield optimal acoustic isolation. To achieve optimal results, it is advised to explore specialized materials and techniques exclusively designed for noise barriers.

- Q:Can steel angles be used as lintels?

- Certainly, steel angles have the ability to function as lintels. Due to their robustness and long-lasting nature, steel angles are frequently employed in construction as lintels. Lintels serve as essential components that bear the weight of walls above an aperture, like a door or window. The exceptional structural support and ability to withstand substantial loads make steel angles particularly suitable for this purpose. In masonry construction, they are frequently utilized to establish a sturdy and secure lintel. Moreover, steel angles can be effortlessly tailored to match precise measurements, rendering them a versatile option for lintel applications.

- Q:Are steel angles suitable for reinforcing concrete structures?

- Yes, steel angles are suitable for reinforcing concrete structures. Steel angles are commonly used in construction as they provide strength, stability, and support to concrete structures. By adding steel angles to reinforce concrete, the overall structural integrity of the building or structure is enhanced, ensuring its durability and resistance to various loads and forces.

- Q:Can steel angles be used for signposts?

- Yes, steel angles can be used for signposts. They are commonly used in construction and are known for their strength and durability, making them suitable for supporting signs.

- Q:Can steel angles be used for support structures?

- Yes, steel angles can be used for support structures. Steel angles are commonly used in construction and engineering projects to provide structural support and stability. They are versatile and can be easily welded or bolted together to form sturdy support structures.

- Q:What is the minimum thickness for a steel angle beam?

- The minimum thickness for a steel angle beam depends on various factors such as the load it needs to support, the length of the beam, and the specific steel grade being used. Generally, the minimum thickness for a steel angle beam is determined by structural engineers or professionals in the field, who consider the specific application and design requirements. Steel angle beams are commonly used in construction, framing, and other structural applications. They are designed to provide support and stability, particularly in load-bearing situations. The thickness of the steel angle beam is crucial to ensure its strength and ability to bear the intended load without deformation or failure. To determine the minimum thickness, engineers consider factors such as the maximum load that the beam will experience, the length of the beam, the material properties of the steel being used, and the safety factor required for the application. They use mathematical calculations and structural analysis to determine the appropriate thickness that will meet the necessary structural requirements. It is important to note that there are specific industry standards and building codes that must be followed when designing and constructing steel angle beams. These standards provide guidelines and requirements for minimum thickness, as well as other aspects such as tolerances, dimensions, and connection details. Therefore, it is always recommended to consult with a qualified structural engineer or professional in the field to determine the minimum thickness for a steel angle beam based on the specific requirements of the project. They will consider all relevant factors and ensure that the beam is designed and constructed to provide the necessary strength and safety.

- Q:What are the different types of steel angles used in staircases?

- There are several different types of steel angles that are commonly used in staircases. These angles serve different purposes and are chosen based on the specific requirements of the staircase design. 1. Equal Leg Angle: This is the most common type of steel angle used in staircases. It has equal length legs that form a 90-degree angle. These angles are typically used for structural support and are often found in the framework of the staircase. 2. Unequal Leg Angle: As the name suggests, unequal leg angles have legs of different lengths. These angles are used when one side of the staircase needs more support or when a certain aesthetic look is desired. They are commonly used in stair treads, risers, and stringers to provide stability and strength. 3. L-Shaped Angle: L-shaped angles are used for corner connections in staircases. They have one leg that extends straight and another that is perpendicular to it, forming an L shape. These angles are commonly used in stair handrails, balusters, and brackets to provide support and reinforcement at junctions. 4. Slotted Angle: Slotted angles are specially designed with slots along the length of the angle. These slots allow for easy adjustment and flexibility in the positioning of components in a staircase. They are often used for adjustable stair brackets, tread supports, and other elements that may require fine-tuning during installation. 5. Flat Bar Angle: Flat bar angles, also known as flat stock angles, are made from flat steel bars bent to form a right angle. These angles are used to provide additional support and reinforcement in staircases where extra strength is required. They are commonly used in heavy-duty stair applications or where there is a need for added load-bearing capacity. Overall, the choice of steel angle used in a staircase depends on factors such as load capacity, structural requirements, aesthetic considerations, and the specific design of the staircase. Consulting with a structural engineer or staircase designer can help determine the most suitable type of steel angle for a particular staircase project.

- Q:How do steel angles perform in chemical industry applications?

- Steel angles are widely used in chemical industry applications due to their excellent performance in corrosive environments. These angles, made of high-strength steel, exhibit exceptional resistance to chemicals, acids, and other corrosive substances commonly found in the chemical industry. The chemical industry often involves the handling and processing of various chemicals, which can lead to corrosion and degradation of structural materials. Steel angles, with their high corrosion resistance, provide a reliable and durable solution in such environments. Moreover, steel angles offer excellent load-bearing capacity and structural stability, making them ideal for supporting heavy equipment, tanks, and platforms in chemical plants. Their versatility allows for the construction of various structures and equipment, ensuring the safe and efficient operation of chemical processes. Steel angles can be fabricated into different sizes and shapes, allowing for easy customization to meet specific requirements. This versatility makes them suitable for a wide range of applications such as piping systems, storage tanks, chemical reactors, and support structures. In addition to their corrosion resistance and structural strength, steel angles are also cost-effective. They have a long lifespan, require minimal maintenance, and can withstand extreme temperatures, pressures, and chemical exposures. This durability and low maintenance requirement contribute to reducing downtime and overall operating costs in the chemical industry. Overall, steel angles perform exceptionally well in chemical industry applications by providing a combination of corrosion resistance, structural strength, versatility, and cost-effectiveness. Their ability to withstand harsh chemical environments makes them an essential component in the safe and efficient operation of chemical processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords