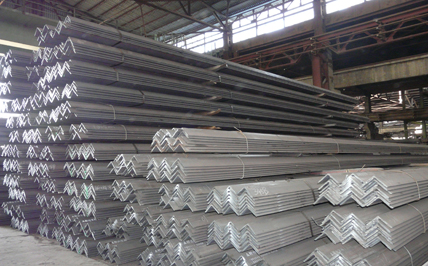

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Equal / L Shaped / Unequal Mild Steel Angle Iron at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal / L Shaped / Unequal Mild Steel Angle Iron are ideal for structural applications and are widely used a variety of architectural and engineering structures, such as beams, bridges, ship; transmission tower, reaction tower; lifting transportation machinery; industrial furnace; container frame, warehouse goods shelves, etc

Product Advantages:

OKorder's Equal / L Shaped / Unequal Mild Steel Angle Iron are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q:What are the typical lengths of steel angles?

- The typical lengths of steel angles vary depending on their intended use and application. However, steel angles are commonly available in standard lengths of 20 feet or 6 meters. These standard lengths are often preferred by manufacturers and construction companies due to their convenience and ease of transportation. Additionally, steel angles can be custom cut to specific lengths as per the requirements of a particular project.

- Q:Can steel angles be used for manufacturing support brackets?

- Indeed, support brackets can be manufactured using steel angles. The construction and manufacturing industries frequently employ steel angles due to their robustness and endurance. Their exceptional support and structural soundness render them perfect for the creation of support brackets. Steel angles are offered in diverse dimensions and thicknesses, enabling customization in accordance with the bracket's precise demands. Moreover, steel angles can be effortlessly welded, drilled, and machined to fit the desired specifications, thus making them an adaptable option for the production of support brackets.

- Q:What is the minimum radius for a curved steel angle beam?

- The minimum radius for a curved steel angle beam depends on various factors such as the size and thickness of the angle beam, the type of steel used, and the specific application requirements. It is recommended to consult structural engineers or refer to relevant design codes and standards for the specific project to determine the appropriate minimum radius for a curved steel angle beam.

- Q:Can steel angles be used for supports in bridges?

- Yes, steel angles can be used for supports in bridges. Steel angles provide structural stability and strength, making them suitable for supporting heavy loads in bridge construction.

- Q:Can steel angles be used in cold-formed steel construction?

- Yes, steel angles can be used in cold-formed steel construction. They are commonly used as structural members in framing systems, providing support and stability to the overall structure. Steel angles are particularly useful in load-bearing walls, roof trusses, and floor systems, as they offer excellent strength and durability. Additionally, their versatility allows for various design possibilities in cold-formed steel construction.

- Q:What are the common methods of joining steel angles together?

- The common methods of joining steel angles together include welding, bolting, and using angle brackets or corner braces.

- Q:Can steel angles be used in high-rise or multi-story buildings?

- Yes, steel angles can be used in high-rise or multi-story buildings. Steel angles are commonly used in construction due to their high strength, versatility, and cost-effectiveness. In high-rise buildings, steel angles are often utilized for various structural elements such as beams, columns, and bracing systems. They provide excellent support for transferring loads and forces within the building, contributing to the overall stability and structural integrity. Moreover, steel angles can be easily fabricated and installed, allowing for efficient construction processes in large-scale projects. Therefore, steel angles are widely accepted and utilized in the construction of high-rise or multi-story buildings.

- Q:How to determine the neutral axis of the angle bar?

- The neutral axis is a line which is the intersection of the neutral plane and the neutral axis corresponding to the strong axis of the cross section. The neutral axis is equal to the bisector of the sectional area parallel to the curved main axis, and the area on both sides of the neutral axis is equal, and the biaxial symmetry section is the centroid axis.

- Q:Can steel angles be used for stairs or handrails?

- Indeed, stairs or handrails can make use of steel angles. In construction, steel angles are frequently employed due to their ability to offer structural support and stability. In the case of stairs, steel angles can be integrated as stringers or supports, guaranteeing the staircase's stability and strength. Similarly, for handrails, steel angles can be utilized as the primary frame or support structure, ensuring a robust and secure handrail for users. The incorporation of steel angles in stairs and handrails presents advantages such as durability, resistance to deterioration, and the capacity to withstand heavy loads, which contribute to their popularity in construction endeavors.

- Q:Can steel angles be used for vehicle frames?

- Certainly, vehicle frames can make use of steel angles. In the construction sector, steel angles are frequently employed due to their structural robustness and adaptability. They possess a diverse array of uses, one of which is constructing vehicle frames. Steel angles offer exceptional support and stability, rendering them well-suited for bearing substantial loads and enduring the various strains and pressures encountered by a vehicle during operation. Furthermore, steel angles can be effortlessly welded or bolted together, allowing for flexibility in the design and construction of vehicle frames. Overall, steel angles present a dependable and long-lasting option for vehicle frames, guaranteeing the vehicle's structural integrity and safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords