Plate feeder with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

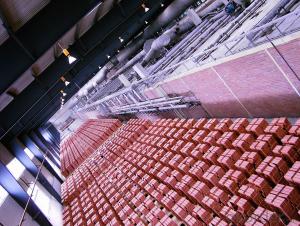

Plate feeder is mainly used to supply material for the next procedure. It is an ideal equipment for controlling the feeding speed and amount of raw materials.

| Type | Production capacity m3/h | Installed capacity (kw) | Width of belt (mm) | Weight (kg) | Dimension (m) |

| BL60 | 35 | 7.5 | 600 | 4749 | 5.6x1.9x1.4 |

| BL80 | 50 | 7.5 | 800 | 5029 | 5.6x2.1x1.4 |

| BL100 | 60 | 7.5 | 1000 | 5389 | 5.6x2.3x1.4 |

| BL120 | 85 | 7.5 | 1200 | 5979 | 5.6x2.5x1.4 |

- Q:Brick machine operating procedures

- Check the electrical part of the fault and leakage phenomenon. Check if the packing concentration is appropriate. Check the triangle belt tightness is appropriate. After the motor is fed to the upper part of the cylinder, open the material gate, so that the material flow to the feeding body cylinder, at this time presses began to work.

- Q:Maintenance method of fly ash brick machine

- In order to make the machinery is often in a good state of technology, to ensure its reliability, improve work efficiency, extend the service life of the machinery to take a series of technical measures. Its main content is to clean, fastening, lubrication and adjustment-based, combined with the relevant inspection and testing work. Various types of machinery and equipment in the "use and maintenance manual" have a clear maintenance requirements, but in actual work this often does not cause enough attention, mainly as follows:

- Q:Where is the brick of the tiles used to make the brick better?

- Its role: 1, with good water permeability, breathability, can quickly penetrate the rain, add soil water and groundwater, to maintain soil moisture, improve the urban ground plants and soil microbial living conditions.

- Q:Automatic concrete brick machine bearing how to choose?

- When the fully automatic concrete brick making machine is running, it should always check whether the bearing seal of the equipment is. The grease in the bearing seat should be filled once every month. Every three months should be cleaned and replaced with oil frying. Normal after feeding, feeding together to be uniform, should be avoided mixed with iron hard objects;

- Q:What kind of configuration does the small semi-automatic cement brick machine include?

- Dosing Machine 2, Cement Warehouse 3, Cement Metering 4, Screw Conveyor 5, Base Material Mixer 6, Pigment Mixer 7, Bottom Belt Conveyor 8, Pigment Belt Conveyor 9, Elevated Horizontal Belt Conveyor 10

- Q:Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Fifth: replace the mold, clean, oil rust, should be set to dry, flat at the support pad flat to prevent gravity deformation.

- Q:Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- Durable features. Feeding mechanism variable speed, rotary disc rotation and other parts of the most advanced technology, transmission power, smooth operation, in place accurate, low maintenance rate advantages.

- Q:Installation and commissioning of hydraulic press

- The factory of the machine in accordance with the relevant provisions of the factory have made the factory test, but due to long-distance transport and a long time to place and other reasons, the installation of hydraulic brick should be the following checks:

- Q:Cement brick machine related issues

- There are many types of cement brick machine, mainly to see what kind of brick you need to produce, and now the main use of a kind of eight-hole turntable, this machine equipment using a wide range of raw materials, the machine's main features are: Convenient, with pressure display, mechanical failure alarm, power supply distance protection, automatic control of oil supply, easy installation and other functions.

- Q:Free burning brick brick brick machine can be how to classify

- According to the structure of the block: divided into a back cover block, not the back of the block, slot block, a slot block.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plate feeder with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products