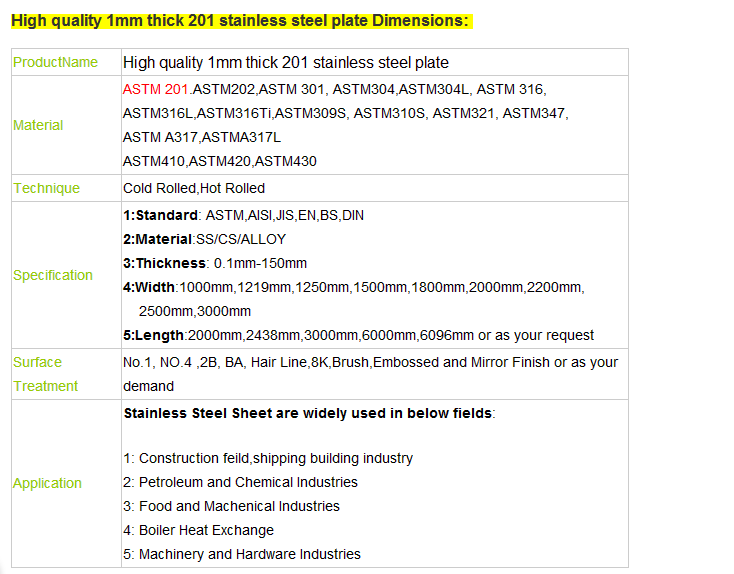

High quality 1mm thick 201 stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Can stainless steel pipes be used for petrochemical plants?

- Certainly, petrochemical plants can utilize stainless steel pipes. Due to its exceptional resistance to corrosion, stainless steel emerges as an optimal selection for such plants that deal with corrosive substances. These pipes possess the ability to endure extreme temperatures and pressures, rendering them appropriate for the demanding operational circumstances of petrochemical plants. Furthermore, stainless steel pipes exhibit outstanding mechanical qualities, guaranteeing their endurance and dependability within industrial settings. Moreover, the ease of cleaning and maintenance associated with stainless steel pipes minimizes the likelihood of contamination and enhances operational efficiency in petrochemical plants.

- Q:Can stainless steel pipes be bent?

- Yes, stainless steel pipes can be bent. Stainless steel is a highly versatile material that possesses excellent strength and ductility, which allows it to be bent without breaking or cracking. The bending process involves using various techniques such as cold bending, induction bending, or hot bending, depending on the desired result and the thickness of the pipe. Stainless steel pipes can be bent to different angles and shapes, making them suitable for a wide range of applications in industries such as construction, plumbing, and automotive. However, it is important to note that the bending process should be performed by professionals or using specialized equipment to ensure the quality and structural integrity of the stainless steel pipes.

- Q:304 stainless steel seamless tube weight how to calculate?

- 304 stainless steel is a common stainless steel material, the density of 7.93 g/cm3, the industry is also called 18/8 stainless steel. High temperature resistance of 800 degrees, with good processability, high toughness characteristics, widely used in industry and furniture decoration industry and food and medical industry.

- Q:Are stainless steel pipes suitable for chemical processing plants?

- Yes, stainless steel pipes are highly suitable for chemical processing plants. Stainless steel is known for its excellent corrosion resistance properties, making it an ideal choice for handling various chemicals and corrosive substances. It is resistant to both organic and inorganic chemicals, acids, and alkalis, ensuring the integrity and longevity of the pipes in harsh chemical environments. Stainless steel pipes also offer high strength and durability, allowing them to withstand high pressures and temperatures commonly found in chemical processing plants. They have excellent heat resistance, which is crucial for handling hot fluids and maintaining the stability of the chemical processes. Moreover, stainless steel pipes have low maintenance requirements and are easy to clean, reducing the risk of contamination and ensuring the purity of the chemicals being processed. They are also resistant to scaling, which can affect the efficiency of the plant's operations. Additionally, stainless steel pipes are non-reactive, meaning they do not leach or contaminate the chemicals being transported. This is particularly important in chemical processing plants where the purity and quality of the products are vital. Overall, stainless steel pipes provide a reliable and efficient solution for chemical processing plants due to their exceptional corrosion resistance, strength, durability, heat resistance, and non-reactivity.

- Q:304 stainless steel pipe, 20*2 pressure, how many kilograms?

- 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304 is equivalent to 0Cr19Ni9 in our country(0Cr18Ni9) stainless steel. 304 chromium 19%, containing nickel 9%. The 304 is the most widely used stainless steel, heat-resistant steel, steel, steel industry utility. For food production equipment, general chemical equipment, nuclear energy, etc..

- Q:Can stainless steel pipes be passivated?

- Yes, stainless steel pipes can be passivated. Passivation is a process that removes contaminants from the surface of stainless steel and forms a protective oxide layer, enhancing its corrosion resistance. This process is commonly used in various industries to ensure the long-term durability and performance of stainless steel pipes.

- Q:How are stainless steel pipes measured?

- Two main parameters are used to measure stainless steel pipes: outer diameter (OD) and wall thickness. The outer diameter corresponds to the pipe's outer circumference, while the wall thickness indicates the thickness of the pipe's walls. These measurements are crucial for determining the pipe's suitability for a particular application and ensuring compatibility with fittings and connectors. Stainless steel pipe dimensions are typically stated in millimeters or inches, and they may vary depending on project requirements or industry standards. Precise measurement is essential to guarantee the correct fitting and functionality of stainless steel pipes in diverse applications, including plumbing, construction, or industrial processes.

- Q:How do you prevent oxidation in stainless steel pipes?

- There are several methods to prevent oxidation in stainless steel pipes. One effective way is to apply a protective coating or finish on the surface of the pipes. This can be done using various types of coatings such as paints, epoxy, or polyurethane. These coatings act as a barrier, preventing oxygen from coming into contact with the stainless steel and therefore reducing the chances of oxidation. Additionally, regular cleaning and maintenance of the pipes is crucial in preventing oxidation. It is important to remove any dirt, debris, or corrosive substances that may have accumulated on the surface of the pipes. This can be done using mild detergents or specialized cleaning agents specifically designed for stainless steel. Another preventive measure is to ensure proper ventilation in the area where the stainless steel pipes are installed. Adequate ventilation helps to minimize the presence of moisture or humidity, which can accelerate the oxidation process. Additionally, keeping the pipes dry and avoiding prolonged exposure to water or moisture is essential in preventing oxidation. Lastly, it is important to select the appropriate grade of stainless steel for the intended application. Different grades of stainless steel offer varying levels of resistance to oxidation. For example, austenitic stainless steel grades such as 304 and 316 are highly resistant to oxidation and are commonly used in applications where corrosion resistance is crucial. Overall, a combination of preventive measures such as protective coatings, regular cleaning, proper ventilation, and selecting the appropriate stainless steel grade can help effectively prevent oxidation in stainless steel pipes.

- Q:What are the different types of stainless steel pipe hangers?

- There are several different types of stainless steel pipe hangers available, each designed to suit specific applications and requirements. Some of the common types include: 1. Split ring hangers: These hangers consist of a split ring that wraps around the pipe, providing support and stability. They are easy to install and adjust, making them suitable for a wide range of pipe sizes. 2. Clevis hangers: Clevis hangers feature a U-shaped bracket that attaches to the pipe and is secured with a clevis pin. They offer excellent load-bearing capacity and are often used in vertical pipe installations. 3. Swivel ring hangers: Swivel ring hangers are designed to allow the pipe to move freely, accommodating thermal expansion and contraction. They consist of a circular ring that can rotate, reducing stress on the pipe. 4. Riser clamps: Riser clamps are used to support vertical pipes that run along walls or beams. They are available in various designs and can be adjustable to accommodate different pipe sizes and configurations. 5. Beam clamps: Beam clamps are used to secure pipes to overhead beams or structures. They typically have a bolt or threaded rod that attaches the clamp to the beam, providing a secure mounting point. 6. Pipe rollers: Pipe rollers are used to support pipes that need to move horizontally, such as in a sliding or rolling application. They consist of a set of rollers or wheels that allow the pipe to move smoothly. 7. Pipe straps: Pipe straps are simple, cost-effective hangers that wrap around the pipe and attach to a surface using screws or bolts. They are commonly used for light-duty applications or where space is limited. 8. Pipe saddles: Pipe saddles are used to support pipes that need to be raised or protected from direct contact with a surface. They typically have a curved or U-shaped design that cradles the pipe. It is important to select the appropriate type of stainless steel pipe hanger based on the specific requirements of the installation, including pipe size, load capacity, movement, and environmental factors. Consulting with a knowledgeable supplier or engineer can help in choosing the right hanger for the job.

- Q:Can stainless steel pipes be used for dairy industries?

- Yes, stainless steel pipes can be used for dairy industries. Stainless steel is a popular choice for piping in dairy industries due to its many desirable properties. Stainless steel pipes are corrosion-resistant, which is crucial in the dairy industry where exposure to acids and other corrosive substances is common. They are also easy to clean and maintain, which is important for maintaining hygienic conditions in dairy processing plants. Additionally, stainless steel pipes are non-reactive, meaning they do not interact with the dairy products and alter their taste or quality. Furthermore, stainless steel pipes have high strength and durability, making them suitable for the high-pressure and high-temperature conditions often found in dairy processing. Overall, stainless steel pipes are a reliable and efficient choice for the dairy industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High quality 1mm thick 201 stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords