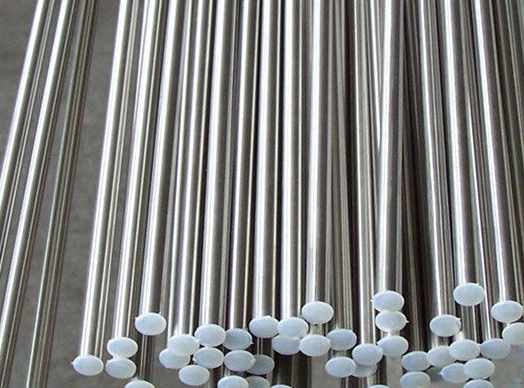

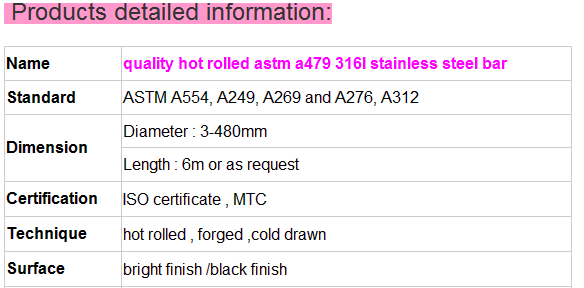

quality hot rolled astm a479 316l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Can stainless steel pipes be used for solar energy systems?

- Yes, stainless steel pipes can be used for solar energy systems. Stainless steel is a versatile and durable material that can withstand the harsh conditions of solar energy systems. It is resistant to corrosion, which is crucial for the longevity of the pipes in outdoor and exposed environments. Stainless steel pipes also have excellent heat resistance properties, making them suitable for transporting hot fluids within solar energy systems. Additionally, stainless steel has a high strength-to-weight ratio, making it ideal for supporting the weight of solar panels or other components in the system. Overall, stainless steel pipes are a reliable and efficient choice for solar energy systems.

- Q:Can stainless steel pipes be used for underground installations?

- Yes, stainless steel pipes can be used for underground installations. Stainless steel is known for its excellent corrosion resistance, which makes it suitable for underground environments where moisture and chemicals are present. It is also highly durable and can withstand harsh conditions, making it a reliable choice for underground installations. Additionally, stainless steel pipes offer high strength and are resistant to cracking or damage, ensuring the longevity of the installation. Overall, stainless steel pipes are a popular choice for underground applications due to their corrosion resistance, durability, and strength.

- Q:Can stainless steel pipes be painted?

- Indeed, it is possible to paint stainless steel pipes. Nevertheless, it should be taken into account that stainless steel is a non-porous substance with a sleek surface, posing difficulties for paint to adhere effectively. In order to achieve proper adhesion, it is advisable to diligently cleanse the surface and utilize a primer specially formulated for stainless steel. This will aid in creating a coarser texture on the surface, facilitating better bonding with the paint. Furthermore, opting for a superior, long-lasting paint suitable for metal surfaces will bolster the durability of the painted coating.

- Q:How do you prevent condensation in stainless steel pipes?

- To prevent condensation in stainless steel pipes, there are several measures you can take: 1. Insulation: Apply insulation materials, such as foam or fiberglass, around the pipes. This will help maintain the temperature inside the pipe, preventing the outer surface from becoming cold and reducing the likelihood of condensation. 2. Vapor barriers: Install vapor barriers around the pipes to prevent moisture from reaching the pipe surface and causing condensation. These barriers can be made of materials like plastic or aluminum foil and should be properly sealed to ensure their effectiveness. 3. Increase pipe temperature: If possible, increase the temperature of the fluid or gas flowing through the pipes. This can be achieved by adjusting the temperature of the heat source or utilizing heat tracing systems that provide a constant heat supply to the pipe. 4. Proper ventilation: Ensure there is adequate airflow around the pipes, especially in areas where condensation is more likely to occur. This helps to dissipate any moisture that may accumulate and reduce the chances of condensation. 5. Reduce humidity: In areas with high humidity, consider implementing dehumidification methods, such as using dehumidifiers or installing moisture-absorbing materials, to lower the overall moisture content in the air. This can help minimize the potential for condensation. By implementing these preventive measures, you can significantly reduce the risk of condensation in stainless steel pipes, thereby protecting them from potential corrosion and maintaining their overall performance and longevity.

- Q:What are the categories of stainless steel pipes with acid and alkali resistance?

- Stainless steel is usually classified according to the organization of the matrix, as follows:The ferritic stainless steel (200 and 400) the chromium content in 15%~30%, with a body centered cubic crystal structure. This kind of steel does not contain nickel, sometimes also contain a small amount of Mo, Ti, Nb and other elements, this kind of steel has high heat conductivity, low expansion coefficient, good oxidation resistance and anti stress excellent characteristics of stress corrosion, used formanufacturingthecorrosionresistanceofthe atmosphere, water vapor, waterandoxidizing parts. Ferritic stainless steel prices are relatively low and stable, and has many unique characteristics and advantages, it has been proved that in many of the original that can only use austenitic stainless steel (300) application of ferritic stainless steel is a very excellent substitute materials, ferritic stainless steel containing nickel, the main elements of Cr (>10%) and iron, chromium stainless steel special corrosion resistant elements, its price is relatively stable.. Chromium 12% ~ 30%. Its corrosion resistance and toughness increase with the increase of chromium content, and the weldability is excellent.

- Q:304 stainless steel will rust it?

- Why is stainless steel rust? When the stainless steel tube surface appear brown rust (point) when people are surprised: "the stainless steel does not rust, rust is stainless steel, steel may be a problem". In fact, this is a lack of understanding of stainless steel one-sided misconceptions. Stainless steel will rust under certain conditions.

- Q:What's the difference between stainless steel 302 and 304?

- Type 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. Model 304 - general model: 18/8 stainless steel. GB is 0Cr18Ni9. 302 and 304 stainless steel is widely used in curtain walls, side walls, roofs and other building applications. These two, I think, are basically different. The quality and texture are almost the same.

- Q:Are stainless steel pipes suitable for wastewater treatment ponds?

- Yes, stainless steel pipes are suitable for wastewater treatment ponds. Stainless steel is highly resistant to corrosion, making it an excellent choice for handling wastewater, which can be highly corrosive. The durability and strength of stainless steel pipes allow them to withstand the harsh conditions and chemicals found in wastewater treatment ponds. Additionally, stainless steel pipes are easy to clean and maintain, ensuring efficient and effective wastewater treatment processes. Overall, stainless steel pipes are a reliable and long-lasting option for wastewater treatment ponds.

- Q:What is the difference between Schedule and Nominal Pipe Sizes for stainless steel pipes?

- Schedule and Nominal Pipe Sizes are both used to describe stainless steel pipes, but they refer to different aspects of the pipe. Schedule refers to the wall thickness of the pipe and is denoted by a number. It is a standardized system used to categorize pipes based on their wall thickness. The schedule number indicates the thickness of the pipe in relation to its diameter. For example, a Schedule 40 pipe has a thicker wall than a Schedule 10 pipe of the same diameter. The higher the schedule number, the thicker the wall. On the other hand, Nominal Pipe Size (NPS) refers to the approximate inner diameter of the pipe and is expressed in inches. NPS is a non-dimensional size designation that does not correspond directly to the actual dimensions of the pipe. It is used as a convenient reference for pipe identification and is often used in conjunction with the schedule number to specify a particular pipe. In summary, the main difference between Schedule and Nominal Pipe Sizes for stainless steel pipes lies in what they describe. Schedule indicates the wall thickness, while Nominal Pipe Size refers to the approximate inner diameter of the pipe. Both are important factors to consider when selecting the appropriate stainless steel pipe for a specific application.

- Q:What is the maximum length of stainless steel pipes available?

- The maximum length of stainless steel pipes available can vary depending on the manufacturer and supplier. Generally, stainless steel pipes can be produced in lengths up to 12 meters (40 feet). However, it is important to note that some manufacturers may offer longer lengths as per customer requirements. Therefore, it is recommended to check with the specific manufacturer or supplier to determine the maximum length of stainless steel pipes they offer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

quality hot rolled astm a479 316l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords