Hot Rolled JIS Standard H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled JIS Standard H-beam Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Hot Rolled JIS Standard H-beam Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Hot Rolled Steel H-beam For Sale

1. Standard: JIS

2. Grade: SS400

3. Length: 12m

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

H x B

(mm)

| T1 | T2 | JIS Weight

(kg/m)

| GB Weight

(kg/m)

|

100*100 | 6 | 8 | 16.9 | 17.2 |

125*125 | 6.5 | 9 | 23.6 | 23.8 |

150*75 | 5 | 7 | 14 | 14.3 |

148*100 | 6 | 9 | 20.7 | 21.4 |

150*150 | 7 | 10 | 31.1 | 31.9 |

175*90 | 5 | 8 | 18 | 18.2 |

175*175 | 7.5 | 11 | 40.4 | 40.4 |

198*99 | 4.5 | 7 | 17.8 | 18.5 |

200*100 | 5.5 | 8 | 20.9 | 21.7 |

194*150 | 6 | 9 | 29.9 | 31.2 |

200*200 | 8 | 12 | 49.9 | 50.5 |

248*124 | 5 | 8 | 25.1 | 25.8 |

250*125 | 6 | 9 | 29 | 29.7 |

244*175 | 7 | 11 | 43.6 | 44.1 |

250*250 | 9 | 14 | 71.8 | 72.4 |

298*149 | 5.5 | 8 | 32 | 32.6 |

298*201 | 9 | 14 | 65.4 | |

300*150 | 6.5 | 9 | 36.7 | 37.3 |

294*200 | 8 | 12 | 55.8 | 57.3 |

300*300 | 10 | 15 | 93 | 94.5 |

346*174 | 6 | 9 | 41.2 | 41.8 |

350*175 | 7 | 11 | 49.4 | 50 |

340*250 | 9 | 14 | 78.1 | 79.7 |

350*350 | 12 | 19 | 135 | 137 |

400*200 | 8 | 13 | 65.4 | 66 |

390*300 | 10 | 16 | 105 | 107 |

400*400 | 13 | 21 | 172 | 172 |

446*199 | 8 | 12 | 65.1 | 66.7 |

450*200 | 9 | 14 | 77.9 | 79.5 |

440*300 | 11 | 18 | 121 | 124 |

496*199 | 9 | 14 | 77.9 | 79.5 |

500*200 | 10 | 16 | 88.2 | 89.6 |

488*300 | 11 | 18 | 125 | 129 |

596*199 | 10 | 15 | 92.5 | 95.1 |

600*200 | 11 | 17 | 103.4 | 106 |

588*300 | 12 | 20 | 147 | 151 |

700*300 | 13 | 24 | 182 | 185 |

800*300 | 14 | 26 | 207 | 210 |

900*300 | 16 | 28 | 240.1 | 243 |

Usage & Applications of Hot Rolled Steel H-beam For Sale

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam For Sale

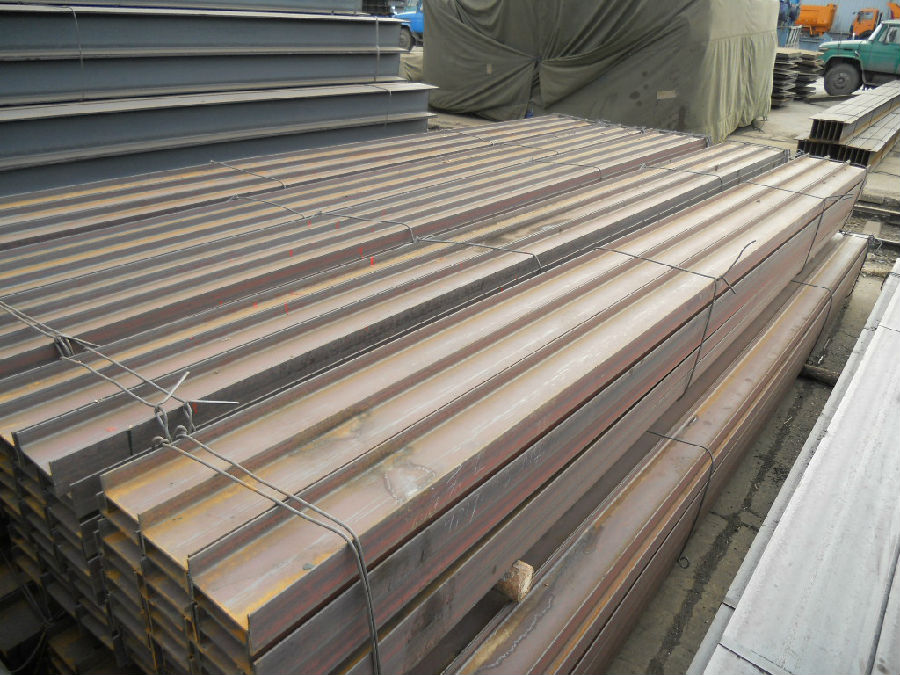

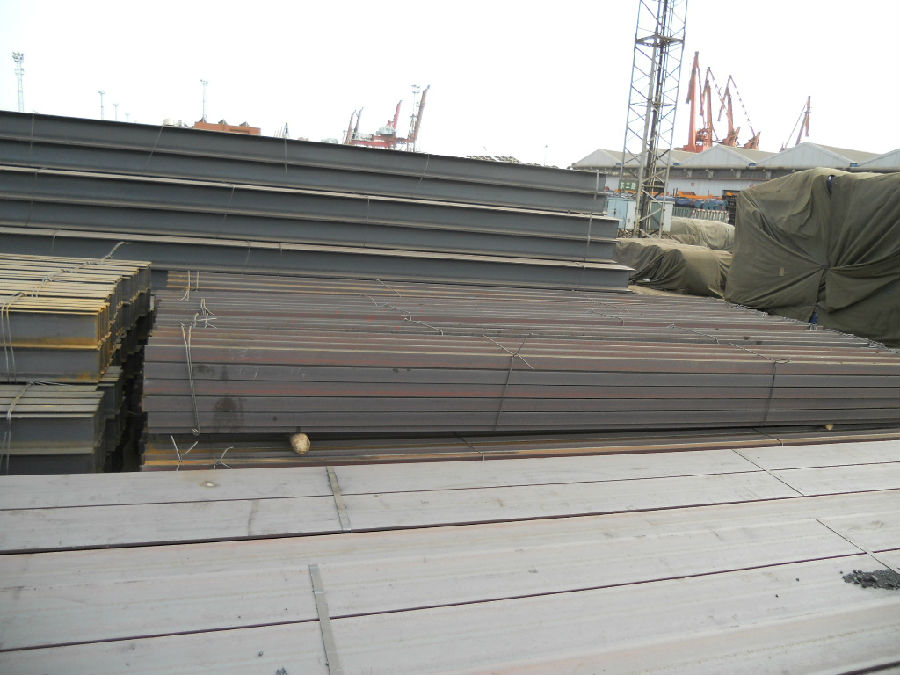

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:How are steel H-beams manufactured?

- Steel H-beams are manufactured through a process called hot rolling, where molten steel is poured into molds and then passed through a series of rollers to shape it into the desired H-beam profile. The heat and pressure applied during hot rolling help to achieve the required strength and structural integrity of the beams. After the hot rolling process, the H-beams are further cooled, cut to the desired length, and undergo various quality checks before being ready for use in construction projects.

- Q:How do you calculate the torsional constant for steel H-beams?

- To calculate the torsional constant for steel H-beams, you need to consider the geometry and dimensions of the beam. The torsional constant, denoted as J, represents the resistance of the beam to torsional or twisting loads. The formula to calculate the torsional constant for an H-beam is given by: J = ((b1 * h1^3) + (b2 * h2^3))/3 Where: J = Torsional constant b1 = Flange width of the top flange h1 = Flange height of the top flange b2 = Flange width of the bottom flange h2 = Flange height of the bottom flange First, measure the dimensions of the H-beam, specifically the flange width and height for both the top and bottom flanges. Ensure that the measurements are in the same units, such as inches or millimeters. Next, substitute the measured values into the formula. Square the height values (h1 and h2) and cube the height values (h1^3 and h2^3). Multiply the appropriate flange width and the cubed height for each flange, and sum them together. Divide the result by 3 to obtain the torsional constant (J). It's important to note that the torsional constant assumes a uniform distribution of torsional stress across the section and neglects any warping effects. Therefore, it provides an approximate measure of the beam's resistance to torsion. For accurate results, it is recommended to consult relevant engineering specifications or perform detailed structural analysis using advanced software.

- Q:How do Steel H-Beams contribute to the overall occupant productivity of a building?

- There are several ways in which steel H-beams significantly enhance the productivity of building occupants. To begin with, these beams offer exceptional support and stability to the building, creating a safe and secure environment that allows individuals to focus on their work without concerns about the building's stability. Additionally, the high load-bearing capacity of steel H-beams enables the construction of larger and more open spaces. This open layout promotes collaboration and communication among occupants, fostering a more efficient and productive work environment. The absence of obstructive columns or walls also allows for flexible space planning, making it easier to accommodate different work styles and adapt to changing needs. Moreover, steel H-beams have a high strength-to-weight ratio, allowing for the construction of taller and more spacious buildings while maintaining safety. This feature not only provides ample natural light and views from higher floors, but also improves the overall well-being and productivity of occupants. Furthermore, steel H-beams are highly durable and resistant to various environmental factors such as fire, earthquakes, and severe weather conditions. This durability ensures the longevity of the building, minimizing disruptions to occupants' work routines and reducing the need for frequent renovations or repairs. Lastly, the ease of fabrication and installation of steel H-beams contributes to shorter construction time and lower costs. This efficiency allows occupants to move into the building sooner and start their operations faster, maximizing their productivity. In conclusion, the utilization of steel H-beams in building construction greatly enhances occupant productivity by providing structural stability, creating open and collaborative spaces, optimizing natural light and views, ensuring durability, and enabling faster construction.

- Q:Can steel H-beams be used in the construction of commercial buildings or offices?

- Yes, steel H-beams can be used in the construction of commercial buildings or offices. H-beams are widely used in the construction industry due to their strength, durability, and load-bearing capabilities. They provide structural support and can withstand heavy loads, making them suitable for larger commercial buildings and office spaces. Additionally, steel H-beams are versatile and can be easily customized to meet the specific requirements of a construction project.

- Q:Can steel H-beams be used in data center construction?

- Yes, steel H-beams can be used in data center construction. Steel H-beams are commonly used in construction projects due to their strength, durability, and versatility. They provide excellent load-bearing capabilities, making them suitable for supporting heavy equipment and structures in data centers. Additionally, steel H-beams offer a high degree of flexibility in design and can be easily customized to meet specific construction requirements. Their use ensures the stability and longevity of the data center, making them a popular choice in the construction industry.

- Q:How do steel H-beams perform in extreme weather conditions, such as high winds or heavy snow?

- Steel H-beams perform exceptionally well in extreme weather conditions, including high winds and heavy snow. Their robust structural design and high strength-to-weight ratio make them highly resistant to bending, twisting, and buckling under these conditions. Additionally, the steel used in H-beams is known for its durability and ability to withstand harsh climates without compromising its structural integrity. Overall, steel H-beams are a reliable choice for withstanding extreme weather conditions.

- Q:How do steel H-beams perform in areas with high levels of wind or hurricane force?

- Steel H-beams perform exceptionally well in areas with high levels of wind or hurricane force. Due to their robust structural design, they offer superior strength and resistance against strong winds and extreme weather conditions. The H-shape of the beams allows for efficient distribution of forces, making them highly reliable in maintaining structural integrity during severe storms. As a result, steel H-beams are widely used in construction projects located in hurricane-prone regions to ensure the safety and durability of buildings.

- Q:What is the weight per meter of steel H-beams?

- The weight per meter of steel H-beams can vary depending on their size and specifications. Generally, the weight of steel H-beams is calculated by multiplying the cross-sectional area of the beam by the density of steel, which is typically around 7850 kilograms per cubic meter. To determine the weight per meter, you would need to know the dimensions of the H-beam, including its height, width, and flange thickness. By calculating the cross-sectional area using these dimensions, you can then multiply it by the density of steel to obtain the weight per meter. For example, let's say we have an H-beam with a height of 200 millimeters, a width of 100 millimeters, and a flange thickness of 10 millimeters. The cross-sectional area of this beam would be (200 * 100) + 2 * (10 * 100), which equals 22,000 square millimeters or 0.022 square meters. Assuming a density of steel of 7850 kilograms per cubic meter, the weight per meter of this H-beam would be 0.022 * 7850 = 173 kilograms per meter. It's important to note that this is just an example calculation, and the weight per meter can vary depending on the specific dimensions and specifications of the steel H-beams.

- Q:How do you calculate the deflection limits for steel H-beams under dynamic loads?

- To calculate the deflection limits for steel H-beams under dynamic loads, several factors need to be considered. Firstly, it is important to determine the type of dynamic load that the H-beam will be subjected to. Dynamic loads can be categorized into two main types: impact loads and vibration loads. Impact loads typically occur due to sudden and intense forces, such as a falling object, while vibration loads result from repetitive or oscillatory forces, such as machinery or wind. Next, the beam's material properties, such as the Young's modulus (E) and the moment of inertia (I), need to be known. These properties provide information about the beam's stiffness and resistance to bending. Once the type of dynamic load and the material properties are known, the deflection limits can be determined using several methods. The most common approach is to calculate the maximum allowable deflection based on the beam's maximum permissible stress. This is often expressed as a percentage of the beam's span or a specific limit in millimeters. Another method involves calculating the natural frequency of the beam. By ensuring that the dynamic load's frequency is significantly lower than the beam's natural frequency, excessive deflection can be avoided. This approach is particularly important for vibration loads. In addition to these methods, it is crucial to consider any applicable design codes or standards that govern the deflection limits for steel H-beams under dynamic loads. These codes provide guidelines and safety factors to ensure the structural integrity of the beam. It is worth noting that calculating deflection limits for steel H-beams under dynamic loads requires expertise and knowledge of structural engineering principles. Therefore, it is recommended to consult with a qualified structural engineer or refer to established design codes to ensure accurate and safe calculations.

- Q:What are the factors to consider when selecting steel H-beams for a construction project?

- When selecting steel H-beams for a construction project, several factors need to be considered. These factors include the required load-bearing capacity, the length and size of the beams, the material grade and quality, the cost, and the supplier's reputation. It is important to ensure that the selected H-beams can withstand the expected loads and meet the project's structural requirements while considering the budget and ensuring a reliable and reputable supplier.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled JIS Standard H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords