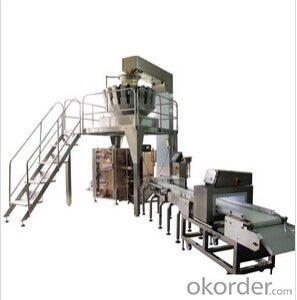

VG42 High Speed Packaging Machine ( MD18 heads combination weigher)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a professional manufacturer of food packaging machines. We are major in the packing machine for more than 11 years.

In China, we are the leading company in this area. Our machine exported over 40 countries and welcomed by the customers since good quality but inexpensive. The best quality of the machine will make user increase productivity and reduce maintenance costs, achieve higer economic efficiency. We got CE & ISO9001:2000 certification. Also, we have perfect after-sale service, when the packing machine has problems just send us an E-mail, our engineer will reply you how to solve the problem or go to your factory. We have the comprehensive abilities in many fields such as design and development of whole projects, production and manufacture, installation and testing, technical training and surpport. Adhering to the spirit of "quality, efficiency, credibility and practicality", we guarantee the high quality of our products.

With the market spreading over Europe, America and Southeast Asia, we sincerely hope to cooperate with customers from all over the world. Please contact us for more details. We ensure to provide qualified products with the best service.

VG42 high speed packaging machine

* Three Specifications

The machine is controlled by three servor motors, with continuou pulling film system and of maximum speed can catch 120 bags/min

Item | Content |

Capacity | 100-120 bags/min |

Bag size | (L)50-300mm (W)50-200mm |

Max film width | 420mm |

Film thickness | 0.04-0.09mm |

Pulling belt type | Intermittent pulling film |

Air consumption | 0.8Mpa 0.3m3/min |

Main power/voltage | 4KW/220V 50/60Hz |

Dimension | L1850*W1100*H1450mm |

Weight | 700kg |

Features

servo motors for film drawing down system. Automatic film rectifying deviation function.

* Horizontal sealing controlled by servo motor;

* Famous brand PLC. Pneumatic system for vertical seal and horizontal seal;

MD18 heads combination weigher

Features

*Adopt high precision digital weighing load cell and A/D module to get preciser weighing than before.

*LCD operating display with multiple languages such as English, Russian, German, Spanish,Italian, etc.

Specification

Item | Parameter |

Drive method | Stepper motor |

The max weighing | 3000g |

Type of weight setting | 99types |

Accuracy | ±0.1~1.5g |

Max capacity | *80bags/min |

Hopper Capacity | 150-2000ml |

Type of hopper | Double layer without memory |

Dimension | L1150xW950xH1129mm |

Voltage | 2KW 50/60/HZ 220V |

TK9 Z type Bucket Elevator (including the vibration feeder)

Features

The conveyor is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. It’s used for vertical feeding of grain or small block material.

Supporting Platform

Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher. In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

Specification

The size of the supporting platform is according to the type of the machines.

TP200 Finished Products Conveyor

Features

Automatically transport the finished products to the turn table which can rotation 360° convenient packaging.

- Q:What is the delay time of the packer's cross sealing?

- There is also a delay in the end of the last movement of the machine to the beginning of the sealing action.

- Q:What are the main functions of packaging machinery and equipment?

- Sealing and other major operations, and related processes before and after,

- Q:How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q:How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resinUre-aformaldehyde resinsUrea formaldehyde polymer. Also called urea formaldehyde resin. The cross-linking English abbreviation UF. molding, the product is insoluble and infusible thermosetting resin, urea formaldehyde resin cured phenolic resin than the color of light, translucent resistance, weak acid and weak alkali, good insulation properties, excellent wear resistance, low price but, in case of strong acid and strong alkali decomposition, weather resistance is poor. The name Beetle. urea and 37% formaldehyde aqueous solution can be obtained by the polycondensation of linear urea formaldehyde oligomer in catalytic acid or alkali industry, with alkali as catalyst, reaction temperature of about 95, the molar ratio of formaldehyde to urea as 1.2.0, to ensure that the resin curing reaction. The first step to generate and dimethylol urea, then hydroxymethyl amino and soluble resin by further condensation, if by acid catalysis, easy to cause the product to be stored to gel. In neutral condition. The linear UF resin for ammonium chloride Curing agent can be cured at room temperature. The molding powder at 130 to 160 DEG C heat curing accelerators such as zinc sulfate, trimethyl phosphate, two oxalic acid ethyl ester can accelerate the curing process. The urea formaldehyde resin is mainly used in the manufacture of molded plastic manufacturing, daily life products and appliance parts, also can be used as adhesive, paper and fabric sheet the pulp, plywood, decorative board and so on. Because of its light color and easy coloring, products often colorful and magnificent.

- Q:Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

- Q:The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q:What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q:Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q:The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping machinery should have rolling, holding, brushing, packaging machinery, bagging, weighing, sealing.

- Q:Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It's a good mechanical design problem! In principle, yes, for example, to achieve the rated torque of the motor. He'll stop by himself! What isn't that great torque? You can zoom in on the load torque

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

VG42 High Speed Packaging Machine ( MD18 heads combination weigher)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords