Aluzinc Steel Sheet for Roofing with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Sheets Description:

Hot-dip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

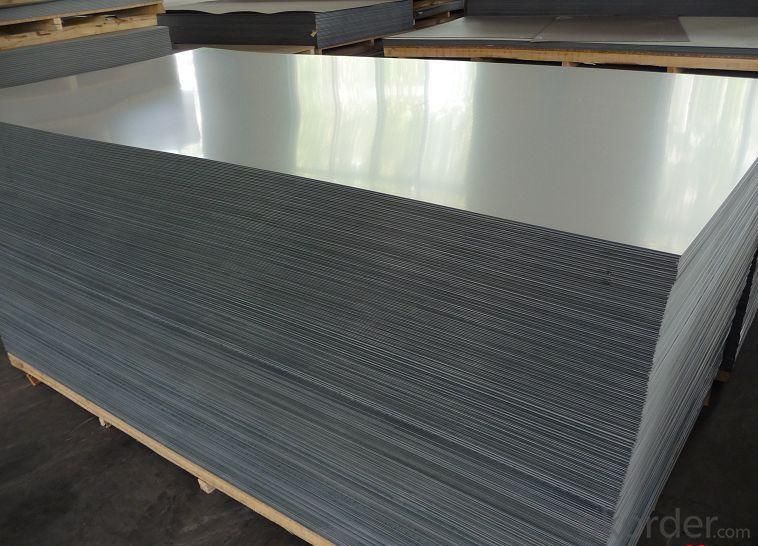

3. Aluzinc Steel Sheets Images

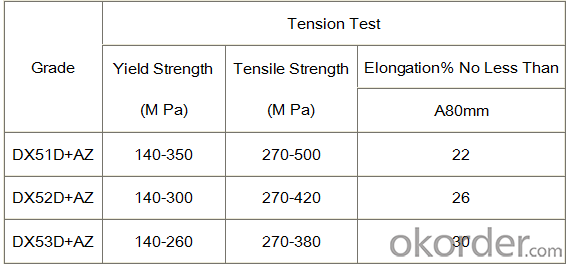

4.Aluzinc Steel Sheets Specification

Thickness: 0.3-0.7mm

Width: 914-1250mm

Inner Diameter: 508-610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Sheets

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How do steel sheets handle static electricity?

- Steel sheets possess excellent electrical conductivity, including the conduction of static electricity. This is due to their high electrical conductivity, allowing them to swiftly eliminate any static charge that accumulates on their surfaces. The effectiveness in handling static electricity is mainly attributed to the presence of unbound electrons within the atomic structure of the steel. When a static charge is applied to a steel sheet, these unbound electrons promptly relocate themselves, nullifying the charge and preventing the accumulation or release of static electricity. Furthermore, steel sheets are frequently coated with a thin protective layer, such as zinc or paint, which further enhances their capacity to dissipate static charges. In general, steel sheets are renowned for their dependable performance in managing static electricity and are commonly utilized in various industrial applications where electrostatic discharge may pose risks to safety or cause damage.

- Q:Can steel sheets be used for automotive suspension components?

- Yes, steel sheets can be used for automotive suspension components. Steel is a commonly used material in the automotive industry due to its strength and durability. It can provide the necessary support and stability required for suspension components to withstand various driving conditions and loads.

- Q:What's the good way to connect two Q235 steel bolts? Why?

- The two scheme should be avoided by 1 reasons, is not easy to locate; 2, the mechanical strength is lower than that of Q235 steel plate bolt, bolt if 8.8 or 10.9 has no significance; 3, time is in low efficiency and tap plate fees, high production cost. Only when the space of the tightening nut is not enough can the connection mode of the steel plate upside screw thread be adopted.

- Q:Can steel sheets be used for manufacturing electrical enclosures?

- Indeed, it is possible to utilize steel sheets in the production of electrical enclosures. The durability, strength, and capability of steel to provide essential safeguarding for electrical components have rendered it a widely employed material for constructing such enclosures. By employing steel sheets, one can ensure that the enclosure possesses robustness and can endure diverse environmental conditions. Furthermore, steel possesses commendable electromagnetic shielding properties, which aid in safeguarding delicate electronic equipment against interference. Additionally, steel sheets are resistant to fire, rendering them appropriate for manufacturing enclosures that must adhere to safety regulations. In summary, steel sheets are a dependable option for fabricating electrical enclosures due to their attributes and appropriateness for the intended purpose.

- Q:What are the different methods of cleaning steel sheets?

- There are several methods of cleaning steel sheets, including mechanical methods such as scrubbing or sanding, chemical methods like using solvents or detergents, and thermal methods like heat treating or flame cleaning.

- Q:Can steel sheets be used for elevator panels or interiors?

- Yes, steel sheets can be used for elevator panels or interiors. Steel is a durable and versatile material that can provide a sleek and modern look to elevator designs. It is commonly used in the construction of elevator interiors due to its strength, resistance to wear and tear, and ease of maintenance.

- Q:What are the color options for steel sheets?

- The color options for steel sheets can vary, but some common choices include silver, black, white, gray, and various shades of metallic colors such as bronze or copper. Additionally, steel sheets can also be painted or coated with a variety of colors to suit specific preferences or design requirements.

- Q:How do steel sheets compare to wood sheets?

- Steel sheets and wood sheets have distinct differences in terms of strength, durability, and use cases. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads, extreme weather conditions, and are highly resistant to warping, rotting, and insect damage. Wood sheets, on the other hand, are less robust and can be vulnerable to moisture, termites, and decay if not properly treated or maintained. In terms of versatility, steel sheets offer a wide range of applications. They are commonly used in construction, automotive, and manufacturing industries due to their high tensile strength and structural stability. Wood sheets, on the other hand, are often used in interior design, furniture making, and smaller-scale construction projects due to their natural aesthetic appeal and ease of manipulation. Additionally, steel sheets are fire-resistant, making them a safer option compared to wood sheets, which are combustible and can contribute to the spread of fire. Steel sheets also have a longer lifespan, requiring less maintenance and replacement compared to wood sheets, which may need regular refinishing, sealing, or replacement due to wear and tear. However, wood sheets have their advantages as well. They are typically more cost-effective than steel sheets, making them a popular choice for budget-conscious projects. Wood sheets also have better insulation properties, providing natural warmth and soundproofing qualities. Ultimately, the choice between steel sheets and wood sheets depends on the specific requirements of the project, including factors such as budget, desired aesthetics, structural needs, and environmental considerations.

- Q:Are steel sheets resistant to warping or bending?

- Steel sheets are generally known for their high tensile strength and stiffness, making them resistant to warping or bending. They are highly durable and can withstand heavy loads without deforming. However, it is important to consider that the thickness and quality of the steel sheet can affect its resistance to warping or bending. Thicker steel sheets tend to be more resistant compared to thinner ones. Additionally, factors like temperature changes and improper handling or installation can also impact the ability of steel sheets to resist warping or bending. Despite these factors, steel sheets are widely used in various industries due to their exceptional resistance to warping or bending.

- Q:Can steel sheets be perforated or embossed?

- Yes, steel sheets can be perforated or embossed. Perforation involves creating holes or a pattern of holes in the steel sheet, while embossing involves creating raised or sunken designs on the surface of the steel sheet. Both techniques are commonly used in various industries for functional or decorative purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluzinc Steel Sheet for Roofing with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords