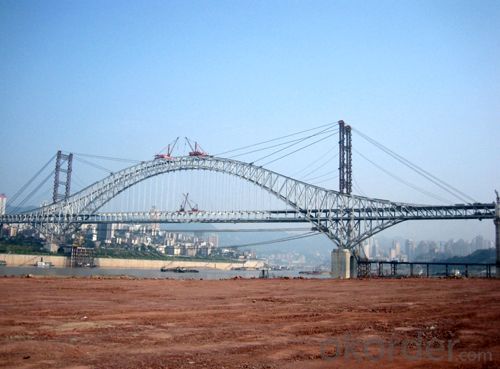

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

| Model Number | B |

| Material | Metal |

| Drawing for design | According to your requirement.We can quote according to your drawing. |

| Surface Treatment | Hot galvanized,painted,powder coated |

Packing Details

| a)Steel strip. |

| b)According to the customers' requirement |

Payments and Shipping Terms

| MOQ | 25 Ton |

| Supply Ability | 100 ton/Month |

| Payment Term | a)L/C b)T/T |

| FOB Shanghai Price | USD1000-1200/Ton |

Check Below for more imformation on placing an order

| 1. Inquiry-Professional quotation. |

| 2. Confirm the price, lead time, payment term etc. |

| 3. Our sales send the Proforma Invoice. |

| 4.Customer make the payment for deposit and send us Bank receipt. |

5.We will arrange the production & inform the estimated time. |

6. Middle Production:send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

7. End Production:Mass production products photos will send to you for approval. You can also arrange the third party Inspection. |

8. Clients make payment for balance and we Ship the goods .Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients. |

9. Order can be say “finish” when you receive the goods and satisfy with them . |

10. Feedback to us about Quality , Service, Market Feedback & Suggestion. And we will do better. |

- Q:How are steel structures designed to be resistant to corrosion in industrial settings?

- Various methods are employed to ensure that steel structures in industrial settings remain resistant to corrosion. Among these methods, the use of protective coatings is one of the most common. These coatings serve as a barrier between the steel surface and its surroundings, preventing corrosive substances from directly contacting the metal. Examples of protective coatings include paint, epoxy, and galvanizing. Paint coatings are frequently used as the primary defense against corrosion. They create a protective layer that seals the steel surface, preventing moisture and chemicals from reaching the metal. On the other hand, epoxy coatings are more durable and better equipped to withstand harsh industrial environments, making them suitable for such settings. Another effective method of corrosion protection is galvanizing. This involves coating the steel with a layer of zinc, which acts as a sacrificial anode. When exposed to corrosive substances, the zinc layer corrodes instead of the steel, thus safeguarding it. Galvanizing is particularly beneficial in environments with high humidity or exposure to saltwater. In addition to protective coatings, steel structures can be designed with features that minimize the risk of corrosion. Incorporating proper drainage systems, for example, prevents water accumulation on the steel surfaces, thereby reducing the likelihood of corrosion caused by prolonged exposure to moisture. Regular maintenance and inspection are crucial to maintaining the long-term corrosion resistance of steel structures in industrial settings. This includes routine cleaning, inspecting coatings for damage or wear, and promptly repairing any defects or damages. By adhering to these practices, steel structures can preserve their integrity and corrosion resistance, ensuring their longevity in harsh industrial environments.

- Q:What is the role of steel in plumbing and water supply systems?

- Steel plays a vital role in plumbing and water supply systems due to its strength, durability, and corrosion resistance. It is commonly used in various components and infrastructure such as pipes, fittings, valves, and tanks. Firstly, steel pipes are widely used in plumbing and water supply systems due to their high strength and ability to withstand high pressure and temperature. They are commonly used for transporting both cold and hot water, as well as other fluids like gas and sewage. Steel pipes are available in different sizes and thicknesses to accommodate different needs and can be easily welded or threaded to create a seamless network of supply lines. Additionally, steel fittings and valves are crucial in plumbing systems as they allow for proper control and regulation of the water flow. Fittings such as elbows, tees, and couplings are used to connect pipes at different angles and directions, enabling the creation of complex plumbing networks. Valves, on the other hand, are used to control the flow and direction of water, allowing for easy maintenance and repair of the system. Moreover, steel tanks are commonly used for storing water in both residential and commercial buildings. These tanks are designed to be robust and leak-proof, ensuring the safe storage of water for various purposes. Steel tanks can be customized to different sizes and capacities, making them suitable for different applications ranging from small residential water storage to large-scale industrial water reserves. One of the key advantages of steel in plumbing and water supply systems is its corrosion resistance. Steel pipes and tanks are often coated with protective layers such as zinc or epoxy to prevent corrosion and extend their lifespan. This is especially important in areas with harsh water conditions or high levels of chemical contaminants that may cause corrosion and degradation of other materials. In summary, the role of steel in plumbing and water supply systems is indispensable. Its strength, durability, and corrosion resistance make it an ideal choice for various components and infrastructure, ensuring the safe and efficient transportation and storage of water in both residential and commercial settings.

- Q:How are steel structures designed for wind uplift loads?

- Steel structures are designed to withstand wind uplift loads by employing various design techniques and considerations. These are aimed at ensuring the structural integrity and stability of the steel framework under the influence of strong wind forces. Firstly, the design process typically involves calculating the expected wind loads based on the specific location and environmental conditions. This is done in accordance with recognized national or international codes and standards, such as the American Society of Civil Engineers (ASCE) 7 or Eurocode 1. The design of steel structures for wind uplift loads takes into account factors such as the shape and height of the building, its exposure to the wind, and the expected wind speed. These factors are considered to determine the wind pressure that the structure will experience. To resist wind uplift forces, engineers employ a combination of structural elements and connections. The structural elements, such as beams, columns, and braces, are designed to have sufficient strength and stiffness to withstand the wind loads. They are often designed as trusses or frames to efficiently distribute the forces and minimize deformations. The connections between the structural elements are designed to ensure their integrity and transfer the applied forces. These connections are typically bolted or welded and are designed to resist both tension and compression forces. Special attention is given to the connection design, as it can significantly affect the overall strength and stability of the structure. In addition to the structural elements and connections, other design considerations are also important. These include the use of appropriate materials with high strength-to-weight ratios, the consideration of aerodynamic shapes to minimize wind resistance, and the use of bracing systems or shear walls to enhance overall stability. Furthermore, computer-aided design and analysis tools are utilized to simulate the behavior of the structure under wind loads. This allows engineers to optimize the design and identify potential areas of concern, such as areas with high stress concentrations or excessive deflections. Overall, the design of steel structures for wind uplift loads is a complex process that requires careful analysis and consideration of various factors. Through a combination of appropriate design techniques, materials, and connections, steel structures can be effectively designed to withstand the forces imposed by strong winds.

- Q:How are steel structures used in retail and shopping centers?

- Steel structures are commonly used in retail and shopping centers for their strength, durability, and versatility. They provide the framework for the buildings, allowing for large open spaces, high ceilings, and flexible layouts. Steel structures are ideal for supporting heavy loads and can withstand extreme weather conditions, making them a reliable choice for retail spaces. Additionally, their construction process is faster and more efficient compared to traditional building materials, ensuring quicker completion of projects. Overall, steel structures play a crucial role in creating functional and visually appealing retail and shopping centers.

- Q:What are the applications of steel structures in industrial buildings?

- Due to their numerous advantages, steel structures find a wide range of applications in industrial buildings. Firstly, they possess incredible strength and durability, making them ideal for supporting heavy machinery and equipment commonly found in industrial settings. This enables the creation of larger open spaces within the building, offering flexibility in layout and accommodating various production processes. Moreover, steel structures provide great flexibility in terms of design and construction. They can be easily tailored to meet specific requirements and erected swiftly, resulting in time and cost savings. Additionally, steel structures can be expanded or modified easily in the future, allowing for scalability as the needs of the industrial building evolve over time. Another significant application of steel structures in industrial buildings is their ability to withstand harsh environmental conditions. Steel exhibits resistance to fire, corrosion, and pests, ensuring the safety and longevity of the building. This is particularly vital in industrial environments where hazardous materials or processes are frequently present. Furthermore, steel structures are renowned for their sustainability. Steel is a recyclable material, making it an environmentally friendly choice for construction. Moreover, steel structures can be designed to maximize natural light, reducing the reliance on artificial lighting and conserving energy costs. In conclusion, the applications of steel structures in industrial buildings are extensive and diverse. From providing strength and durability to enabling flexibility and customization, steel structures are an exceptional choice for supporting the demanding requirements of industrial environments.

- Q:Can steel structures be designed with skylights or sky domes?

- Yes, steel structures can be designed with skylights or sky domes. The use of steel as a structural material provides flexibility in creating openings for natural light sources. Skylights or sky domes can be incorporated into steel structures, allowing for the introduction of daylight and enhancing the aesthetic appeal of the building.

- Q:How are steel structures used in telecommunications infrastructure?

- Due to their strength, durability, and versatility, steel structures have found wide application in telecommunications infrastructure. They serve as robust support systems for a variety of telecommunications equipment and facilities. A prominent example of steel structures in telecommunications is their use in cell phone tower installation. Steel, being able to withstand harsh weather conditions and provide stability, is the preferred material for constructing these towers. Steel towers can be erected in different heights and designs to optimize signal transmission and coverage. They are also designed to accommodate multiple antennas, microwave dishes, and other wireless communication equipment. Apart from cell phone towers, steel structures are utilized in the installation of other communication infrastructure like satellite dishes and broadcasting towers. Satellite dishes require a sturdy and stable structure to ensure accurate signal reception and transmission. Steel structures offer the necessary support for these dishes, enabling the provision of satellite television, internet, and other communication services. Furthermore, steel structures are employed in the construction of telecommunication equipment shelters or cabinets. These shelters house sensitive telecommunications equipment, including servers, routers, and switches, which necessitate protection from external elements. Steel structures provide a secure and weather-resistant enclosure for these critical components, ensuring their proper functioning and longevity. In conclusion, steel structures have a crucial role in telecommunications infrastructure, providing support, stability, and protection for various communication systems and equipment. Their strength, durability, and flexibility make them an ideal choice for constructing cell phone towers, satellite dishes, communication shelters, and other essential components of the telecommunications network.

- Q:What are the factors to consider when designing steel structures for retail and commercial spaces?

- When it comes to designing steel structures for retail and commercial spaces, there are various factors that must be taken into account. These factors encompass: 1. Load requirements: The foremost consideration in the design of steel structures is to ensure their ability to support the expected loads. This includes the weight of the building itself, as well as the weight of its contents and any additional loads like HVAC systems or machinery. The structural engineer must calculate the necessary load-bearing capacity of the steel components to ensure they can withstand the projected loads. 2. Compliance with building codes and regulations: It is crucial to adhere to local building codes and regulations to ensure the safety and structural integrity of the steel structure. The design must meet all relevant codes, including those pertaining to fire resistance, seismic design, wind loads, and accessibility. 3. Flexibility and adaptability: Retail and commercial spaces often require the ability to adapt to changing needs and layouts. The steel structure should be designed in a way that allows for future modifications or expansions without compromising its stability or integrity. This can involve incorporating provisions for adjustable partitions, removable walls, or flexible floor plans. 4. Architectural aesthetics: The design of retail and commercial spaces is not solely focused on functionality, but also on creating an attractive environment for customers and employees. Steel structures offer a wide range of architectural possibilities, enabling unique and visually pleasing designs. Factors such as the type of steel used, finishes, and integration of other materials should be considered to achieve the desired visual impact. 5. Cost-effectiveness: Steel structures are recognized for their cost-effectiveness in terms of construction time and material efficiency. However, it is important to take the overall project budget into consideration when designing steel structures for retail and commercial spaces. The design should aim to optimize costs without compromising safety or functionality. 6. Energy efficiency: With the increasing emphasis on sustainability, energy efficiency should also be considered. Steel structures can be designed to incorporate insulation, efficient HVAC systems, and natural lighting, thereby reducing energy consumption and operating costs. 7. Maintenance and durability: Retail and commercial spaces often experience high traffic and require regular maintenance. The design should consider factors that facilitate easy maintenance and durability, such as corrosion-resistant coatings, accessible service routes, and durable finishes. In conclusion, the design of steel structures for retail and commercial spaces necessitates careful consideration of load requirements, building codes, flexibility, aesthetics, cost-effectiveness, energy efficiency, and maintenance. By taking these factors into account, architects and engineers can create spaces that are safe, functional, and visually appealing, all while meeting the specific needs of their clients.

- Q:How are steel structures used in the construction of distribution centers?

- Distribution centers rely heavily on steel structures for their construction due to the numerous advantages they offer. Firstly, steel structures are renowned for their durability, strength, and cost-effectiveness, making them an ideal choice for these facilities. One major benefit of steel structures is their ability to bear heavy loads. Given the substantial quantities of goods handled by distribution centers, robust support systems are essential. Steel beams and columns can withstand significant weight, allowing for the creation of spacious storage areas and high ceilings that maximize storage capacity. Moreover, steel structures possess excellent resistance to environmental factors such as fire, moisture, and pests. This is particularly crucial in distribution centers, where the safety and protection of goods are of utmost importance. Steel's inherent fire-resistant properties help prevent the spread of fires and minimize damage. Additionally, steel structures offer flexibility in design and construction. Distribution centers often require customization to meet specific operational needs, such as tall racking systems, mezzanine floors, and conveyor systems. Steel's versatility allows for easy modification and expansion of the facility as business needs evolve. Furthermore, steel construction is relatively faster compared to traditional building materials. The use of pre-engineered components enables off-site fabrication, reducing construction time and ensuring quicker project completion. This advantage is particularly significant for distribution centers that face tight deadlines and must commence operations promptly. Lastly, steel structures provide cost savings over the lifespan of a distribution center. Although the initial investment in steel construction may be higher than other materials, the long-term benefits outweigh the costs. Steel's durability and low-maintenance requirements result in reduced repair and replacement expenses over time. Additionally, steel is recyclable, making it an environmentally-friendly option. In conclusion, the strength, durability, flexibility, and cost-effectiveness of steel structures make them indispensable in the construction of distribution centers. They provide the necessary support for heavy loads, resistance to environmental factors, customization options, and faster construction. Ultimately, steel structures contribute to the efficient and reliable operation of distribution centers.

- Q:What is the cost comparison between steel structures and other construction materials?

- The cost comparison between steel structures and other construction materials can vary depending on various factors such as project size, location, design complexity, and market conditions. However, steel structures are generally considered to be cost-effective due to their durability, versatility, and faster construction times. While steel may have a higher upfront cost compared to materials like wood or concrete, its long-term benefits often outweigh the initial investment. Additionally, steel structures require less maintenance and are less susceptible to damage from pests, fire, and weather, resulting in potential cost savings over time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords