Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

1. AUTOMATIC FEEDING SYSTERM

2. ABB BRAND INVERTER

3. RKC BRAND TEMPERATURE CONTROLLER

PE PIPE PRODUCTION LINE EQUIPMENTS FEATURES:

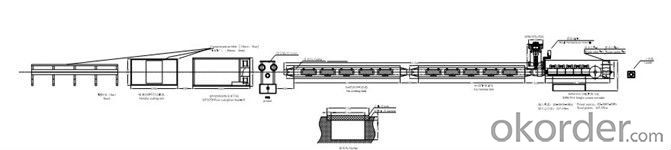

PE pipe production line qingdao benice plastic machinery co.,ltd mainly consists of PE single screw extruder, PE pipe special using mould, PE pipe vacuum calibration water tank, PE pipe drawing machine, PE pipe cutting machine, PE pipe stacker, and the auxiliary machine: SHL200/500 mixer.

PE pipe plastic making machine features:

High speed, high efficiency extrusion single screw extruder is specially designed for extruding PE etc. material, equipped with the lower noise, high speed and hard gear reducer. The Special grooved feeding bush with water cooling system results in increasing compression and filling factors. Specialized screw designs for high output, low melting temperature, good plasticization effection, lower energy consumption.

Spiral diffluence type extrusion die is specially designed for PE extrusion. Unique design of low-pressure inclined flow passage spiral/lattice basket die head, ensures low temperature and high plasticizing extrusion of PE pipes; Special designed die core spiral temperature control, ensures the performance of PE pipes; Multi-layer co-extrusion die offers the advantages of low cost and flexibility of layer structure with different material. it features in easy adjustment and even extrusion, ensures that melting pressure and flux are uniformity, the surface of pipe is smooth and shapely. Skype is benicexiaofei

Plastic PE pipe making machine specifications:

Model | Pipe diameter Range (mm) | Pipe extruder model | Marking- line extruder model | Extrusion speed | Max Output | Total installed power | Dimension |

BAXPEG-50×33-63 | Ø20-Ø63 | BAXSJ-50×33 | BAXSJ-25×25 | 0.3-12 | 120 | 65 | 36 ×2.2 ×2.5 |

BAXPEG-65×33-125 | Ø20-Ø125 | BAXSJ-65×33 | BAXSJ-25×25 | 0.3-12 | 220 | 110 | 56 ×2.2 ×2.6 |

BAXPEG-80×33-160 | Ø63-Ø160 | BAXSJ-65×33 | BAXSJ-30×25 | 0.3-6 | 300 | 150 | 50×2.2 ×2.8 |

BAXPEG-80×33-250 | Ø75-Ø250 | BAXSJ-80×33 | BAXSJ-30×25 | 0.5-5 | 400 | 200 | 52 ×2.2 ×3.0 |

BAXPEG-90×33-400 | Ø160-Ø400 | BAXSJ-90×33 | BAXSJ-30×25 | 0.2-2 | 550 | 280 | 66 ×2.2 ×3.0 |

BAXPEG-90×33-500 | Ø200-Ø500 | BAXSJ-90×33 | BAXSJ-30×25 | 0.1-1 | 700 | 360 | 70 ×2.3 ×3.5 |

BAXPEG-120×33-630 | Ø355-Ø630 | BAXSJ-10×33 | BAXSJ-30×25 | 0.1-1 | 900 | 450 | 72 ×2.3 ×3.5 |

BAXPEG-150×33-1200 | Ø710-Ø1200 | BAXSJ-150×33 | BAXSJ-45×30 | 0.05-0.5 | 1500 | 650 | 80 ×3.0 ×4.0 |

Main Configuration of Plastic Pipe Extrusion Line

Extruder/ Vacuum Shaping part/ Cooling part/ Haul-off Device/ Cutter/ Stirring-up Rack

- Q:What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q:shopping bags, what equipment prices? Raw material type and material price? Please expert advice

- Need injection molding machine and blowing machine, raw materials can be used PE and PP plastic raw particles, using recycled particles, although it can reduce costs, but the quality of products as good as raw materials. To sum up, it is not easy to study a good market and choose a good one.

- Q:Such as title, small items, but also the size of the palm, and want to mass production, plastic, production machinery, abrasives about how much money, the smallest sizeIn addition, the production of plastic products are not required sewage ah, online and other great god!!

- There are thousands of plastic, you first understand some commonly used bar, usually ABS, C material, B material. There are floating water and submerged, and so on. There are 4 kinds of plastic on a mineral water bottle, do you know?

- Q:How are the plastic products made of this texture processed?

- Plastics processing technologyPlastic forming process. It is a general term for various processes that convert synthetic resins or plastics into plastic products. It is a larger manufacturing sector in the plastics industry. Plastic processing generally includes plastic batching, molding, machining, bonding, modification and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.Mixed ingredientsPlastic processing of raw materials, in addition to the polymer, usually also added a variety of plastic additives (such as stabilizer, plasticizer, lubricant, coloring agent, reinforcing agent and filler etc.), to improve the performance of molding process and product or reduce the cost of products. The additive and the polymer are mixed and evenly dispersed into powder, also called dry mixed material. Sometimes, the powder is also processed into pellets. The powders and pellets are referred to as synthetic or moulded plastics.

- Q:Please expert pointing. How high is the profit?. Where are the machines reliable in quality?.

- Profit is not to say, 2000 before doing a ton of 500-1000 net profit, now do a ton of only about 300, but also to do good, large amount of the profit was also lower (puerile) now what things are transparent, not hide what the difference, and too many fakes (it is impurity) also, the factory debt, lead to large investment (scrap price is high, the factory as a result of the large investment in arrears), reliable quality machine: if the water feed on a number of Shandong (lack of the low yield), if the dry material (sheet) on a number of Guangdong Zhongshan presses, the Chinese star can also.

- Q:I am engaged in the plastic processing industry, mainly for ABS and PP through chemical agent for processing, will this be harmful to the body?

- Some large metal washing plants, paper mills, leather factories, food factories, etc., should be used in the use of mechanized operation, reduce manual operation, prevent long time direct contact with the skin. Pregnant women should change jobs appropriately so as not to influence the next generation. The waste water discharged by the factory should be discharged after the sewage treatment has been purified to meet the national discharge standard so as to ensure that our groundwater resources are free from pollution.

- Q:What kind of equipment does the plastic product factory need?

- The current plastic, if the raw materials and semi-finished products are relatively low profits, it is recommended to do directly in the above color printing, the added value of high. Like universal printer, you can achieve this effect. In some plastic shell, plastic, plastic stationery and other top brands.

- Q:Where do engineering plastics processing best?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q:What kind of production equipment will be needed for plastic processing plants for daily necessities?

- 1, the main equipment is injection molding machine, there are many auxiliary machines, such as drying hopper, grinder, mixer, processing products, such as mold.2, plastic products are made of plastic as the main raw materials processed from daily necessities, industrial supplies collectively. Including plastic, raw materials, injection molding, plastic and other products.3, plastic is a kind of synthetic polymer material with plasticity. With synthetic rubber and synthetic fiber, it has become the three most important synthetic materials in daily life. Specifically, the plastic is made of natural or synthetic resin as the main ingredient, adding various additives, in certain conditions such as temperature and pressure can be made into a certain shape, keep shape materials at room temperature.

- Q:I want to make some plastic products. Thank you。 FiveThe four type: first, a one or two meter long, hard, but bent plastic tube. Then there's something like the front end of the syringe. And then a small plastic kettle. Finally, a small thing that can be secured to the mouth of the pipe.

- What other plastic pot instead of well, to know a few thousands of large plastic mold, many tens of thousands of large; if you need a lot of, clear their own requirements, I think there are many manufacturers are willing to do, your preferred OK.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products