Climbing Formwork-Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

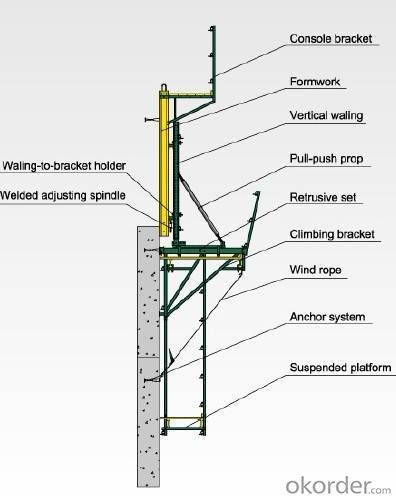

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on.

The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect.

Cantilever formwork has several types, the structure is similar, and has its own different characteristic.The client can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

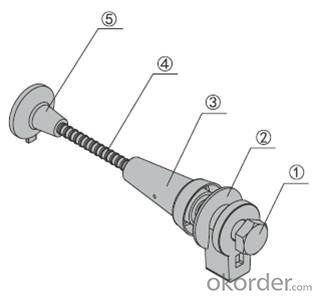

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

We dedicated to the offer the whole formwork solutions to you, which includes the design, manufacture, sale and after-sale services. Please feel free to contact us if you have any requirement.

- Q:Are steel props adjustable with computer-controlled automation systems?

- Yes, steel props can be adjustable with computer-controlled automation systems. These systems utilize advanced technology to control the height and positioning of the steel props. By integrating computer-controlled automation systems, the adjustment process becomes more precise and efficient. These systems can be programmed to adjust the height of the steel props based on specific requirements, such as load-bearing capacity or changes in the structure. Additionally, computer-controlled automation systems allow for real-time monitoring and adjustments, ensuring optimal performance and safety.

- Q:Can steel props be used in the construction of temporary hoardings?

- Indeed, the utilization of steel props is viable for the construction of temporary hoardings. Commonly referred to as steel supports or adjustable steel props, these structures are frequently employed in construction to offer temporary support to various edifices. Their adaptable nature allows for height adjustment, rendering them versatile and appropriate for a multitude of applications. In regard to temporary hoardings, steel props serve to fortify and stabilize the structure. They can be effortlessly installed and modified to meet the required height specifications, ensuring the hoarding's security and capacity to withstand external pressures. Additionally, these steel props possess exceptional durability and strength, making them highly suitable for temporary construction endeavors.

- Q:What are the common maintenance requirements for steel props?

- Some common maintenance requirements for steel props include regular inspection for signs of damage or wear, cleaning and lubricating moving parts, and ensuring proper storage and handling to prevent rust or corrosion. It is also important to follow manufacturer guidelines for the safe and effective use of steel props.

- Q:What are the typical dimensions of a steel prop?

- The typical dimensions of a steel prop can vary depending on the specific manufacturer and the intended use of the prop. However, in general, steel props are commonly available in a range of sizes. The standard dimensions for a steel prop usually include a height that can vary from approximately 1.8 meters to 5 meters. The diameter of the steel tube used for the prop can typically range from 40mm to 60mm. The wall thickness of the tube is typically around 3mm to 5mm, providing enough strength to support the intended load. Steel props are often adjustable in height to accommodate different construction needs. They typically have a threaded screw mechanism or a pin and hole system that allows for easy height adjustment and stabilization. The adjustable range for the height can vary, but it is commonly between 0.5 meters to 1.5 meters. It is important to note that these dimensions are not set in stone and can vary depending on the specific requirements of the construction project or the manufacturer's specifications. Therefore, it is always advisable to check with the supplier or manufacturer to determine the exact dimensions of the steel props you require.

- Q:What are the primary materials used in manufacturing steel props?

- The primary materials used in manufacturing steel props are typically high-quality steel alloys, such as carbon steel or stainless steel.

- Q:How do you install and set up a steel prop?

- Follow these steps for the installation and setup of a steel prop: 1. Begin by assessing the area where the steel prop will be installed to determine the appropriate location. Ensure that the ground is stable and capable of supporting the prop's weight. 2. Next, select a steel prop that matches the required load capacity. Consider factors such as the height and weight that the prop needs to support. 3. Prepare the installation site by clearing away any debris or obstacles. It is important to ensure that there are no underground utilities or cables that could be damaged during the installation process. 4. Position the prop in the desired location, ensuring that it is aligned vertically. Adjust the prop's height to meet the required level or support needed. 5. Use a spirit level to check that the prop is perfectly vertical. Secure the prop in place using a steel prop clamp, ensuring that the clamp is tightened securely to prevent any movement. 6. If necessary, adjust the height of the steel prop to meet the required specifications. This can be achieved by extending or shortening the prop's telescopic sections. 7. Confirm that the prop is supporting the intended load and double-check the weight capacity to ensure it is not exceeded. 8. Conduct regular inspections of the steel prop to ensure it remains secure and properly aligned. Look out for any signs of damage or movement, and take immediate action to rectify any issues that are detected. Always refer to the manufacturer's instructions for the specific steel prop being used. If you are unsure, it is advisable to consult a professional or seek expert advice to ensure proper installation and setup of the prop.

- Q:Are steel props suitable for all types of building materials?

- No, steel props may not be suitable for all types of building materials. The suitability of steel props depends on various factors such as the weight and structural characteristics of the building material, as well as the specific requirements and regulations of the construction project. It is important to consult with structural engineers and construction professionals to determine the appropriate support systems for different building materials.

- Q:Can steel props be used in the construction of dams?

- Yes, steel props can be used in the construction of dams. Steel props, also known as steel supports or steel shoring, are commonly used in construction projects to provide temporary support to structures or excavations. In dam construction, steel props can be utilized during various stages of the project. During the excavation phase, steel props can be used to secure the sides of the excavation and prevent soil or rock collapse. This is crucial to ensure the safety of workers and maintain the stability of the site. Steel props can be adjusted and installed at different lengths to accommodate the specific requirements of the excavation. Additionally, steel props can also be used during the construction of the dam walls. They can be employed to support the formwork or molds used to shape the concrete walls of the dam. Steel props provide stability and strength to the formwork, allowing construction workers to pour and shape the concrete in a controlled manner. Moreover, steel props can be utilized during the maintenance or repair of dams. When certain sections of a dam need to be accessed for maintenance or repair work, steel props can be used to provide temporary support to the surrounding structures. This ensures the safety of workers and prevents any potential collapse or damage to the dam. Overall, steel props are versatile and reliable tools that can be effectively used in the construction of dams. They provide temporary support, stability, and safety, making them an essential component in the construction and maintenance of dams.

- Q:Do steel props require any special certifications or inspections?

- Yes, steel props typically require special certifications and inspections in order to ensure their safety and compliance with industry standards. These certifications and inspections are necessary because steel props are commonly used in construction projects to provide temporary support to structures during construction or renovation. The specific certification requirements may vary depending on the country or region, but in general, steel props are required to meet certain standards such as ISO 9001 (quality management), ISO 3834 (welding quality requirements), and EN 12811-1 (temporary works equipment). Certifications for steel props are typically obtained from accredited certification bodies that specialize in assessing the compliance of construction equipment with relevant standards. These bodies conduct thorough inspections and tests to ensure that the props are structurally sound, have proper load-bearing capacities, and are built to withstand the anticipated working conditions. Inspections of steel props are important to verify their condition and ensure that they are being used correctly and safely on construction sites. Regular inspections help identify any potential defects or signs of wear and tear that could compromise the props' integrity and safety. Inspections are usually carried out by qualified personnel, such as structural engineers or certified inspectors, who are trained to identify any issues and recommend necessary actions, such as repairs or replacements. In summary, steel props typically require special certifications and inspections to ensure their compliance with industry standards and guarantee their safety on construction sites. These measures are in place to protect workers and ensure the stability of structures during construction or renovation projects.

- Q:Can steel props be used in the construction of temporary educational or classroom facilities?

- The construction of temporary educational or classroom facilities can incorporate steel props. These props, also referred to as adjustable steel props or acrow props, are commonly used in construction projects to offer temporary support to walls, ceilings, or other structures during construction or renovation. When it comes to temporary educational or classroom facilities, quick and hassle-free installation is often required, along with the ability to easily relocate or dismantle the structures. Steel props are highly suitable for this purpose due to their lightweight nature, versatility, and ability to be adjusted to different heights. Hence, they can accommodate various types of structures and layouts. Moreover, steel props provide a secure and safe support system for temporary educational or classroom facilities, as they are both durable and stable. Manufactured from high-quality steel, they are designed to withstand heavy loads, ensuring structural integrity and reliability. Furthermore, steel props are a cost-effective option compared to other support systems. They can be rented or purchased at a reasonable price, making them a financially efficient choice for temporary construction projects like educational or classroom facilities. In conclusion, the versatility, durability, and cost-effectiveness of steel props make them a viable option for the construction of temporary educational or classroom facilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Climbing Formwork-Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords