Water Ring Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. high vacuum, low power,high pump speed2. widely used in mining industry

3. ultimate pressure: 33mbar

Instructio

2BV series liquid ring type vacuum pump and compressor as the new generation of energy saving products, its outstanding performance and advantages will replace SK, 2SK series water ring vacuum pump, W, WY, WL series reciprocating vacuum pump.

Advantage

2BV series pump for air and water vapour pressure to breathe, 33mbar absolute pressure (97%), vacuum pump suction pressure when in 80mbar below the condition, long-term work connected with protecting tube cavitation erosion of pump injector, i.e., protecting atmosphere, inspiratory pressure can reach 10mbar, injector pump can be directly mounted in a compressor, the pressure, to 0.26 MPa (maximum absolute pressure).

2BV series water ring vacuum pumps as a new generation energy-saving products, and the excellent performance and numerous advantages will be fully replace with same properties of SK, 2SK series water ring vacuum pumps and W, WY, WL series reciprocating vacuum pump.

Vacuum pump accessories: impeller,disc, the pump cover, pump body materials can be chosen as following:

SUS304 (0Cr18Ni9)

SUS316 (0Cr17Ni12Mo2)

SUS316L (00Cr17Ni14Mo2)

Pump shaft materials:2Cr13, SUS304 and SUS316L

Mechanical seal uses imported products, Seals can use viton or PTFE.

2BV2 - Ex, 2BV6 series water ring type vacuum pump/compressor is mainly used for surking explosive gas, and various inflammable and explosive of working environment, its performance parameters are as the same as 2BV2, 2BV5 series

Model | Max. capacity m3/h | Limiting vacuum | Motor power | Speed | Flowrate | Noise | Weight |

2BV-B060 | 27 |

33mbar

| 0.81 | 2840 | 2.5 | 62 | 37 |

2BV2-B061 | 52 | 1.45 | 2840 | 2.5 | 65 | 41 | |

2BV2-B070 | 80 | 2.35 | 2860 | 3 | 66 | 66 | |

2BV2-B071 | 110 | 3.85 | 2880 | 4.7 | 72 | 85 | |

2BV-E110 | 165 | 4 | 1440 | 7.2 | 63 | 120 | |

2BV-E111 | 230 | 5.5 | 1440 | 8.8 | 68 | 150 | |

2BV-E121 | 280 | 7.5 | 1440 | 11 | 69 | 210 | |

2BV-E131 | 400 | 11 | 1460 | 16 | 73 | 280 | |

2BV-E161 | 500 | 15 | 970 | 22 | 74 | 390 | |

2BV-F110 | 165 | 4 | 1440 | 67 | 63 | 150 | |

2BV-F111 | 230 | 5.5 | 1440 | 10 | 68 | 200 | |

2BV-F121 | 280 | 7.5 | 1440 | 12 | 69 | 230 | |

2BV-F131 | 400 | 11 | 1460 | 17 | 73 | 315 | |

2BV-F161 | 500 | 15 | 970 | 23 | 74 | 426 |

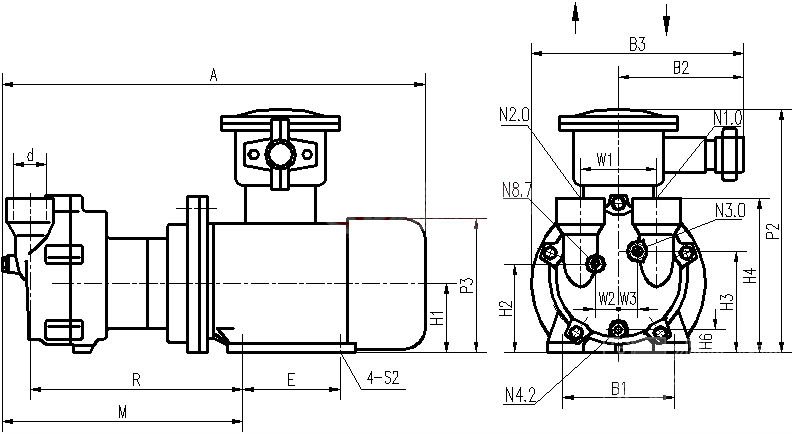

Picture

- Q:Is the diaphragm pump and the drain pump one?

- First of all, there's something wrong with your concept.Diaphragm pump is in accordance with the way the pump classification, drain pump is in accordance with the use of pumps classification.

- Q:What are the general water pump failure, how to repair?

- (4) because of the long latent water and the corrosion of the pipe wall, the water inlet of the water inlet is constantly dropping. When the holes appear above the water, the air enters the water inlet pipe from the hole.(5) there is a crack at the bend of the inlet pipe, and there is a small gap between the inlet pipe and the water pump, which may cause the air to enter the inlet pipe.

- Q:What is a solution pump?

- Principle and structure features of canned motor pumpThe ordinary centrifugal pump is driven by coupling the pump impeller shaft is connected with the motor shaft, the impeller and the motor rotates while working and shielding pump is a kind of non seal pumps, pump and motor is sealed in a medium filled by pumping the pressure vessel, the pressure vessel only static seal and, by a group of wires to provide a rotating magnetic field and drive the rotor. This structure eliminated the traditional centrifugal pump with a rotary shaft sealing device, it can do no leakage.The pump and motor pump together, motor rotor and pump impeller fixed on the same shaft, use of shielding the rotor and the stator of the motor rotor separated in the medium, its power is transferred to the rotor through the stator magnetic field.

- Q:Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- (1) pump connected outside pipes, containers, pipes, joints and other leakage test instrument, large leakage, rotary gas plug exhaust sound big, and the gas and oil mist discharge, should find leakage cancellation.(2) the assembly of rubber of intake pipe is not proper, damage or aging should be adjusted or replaced.(3) plug hole, the vacuum degree can be decreased, put the oil, remove the tank, loosen the nozzle plate, pull out the oil inlet nozzle, dredge oil hole, try not to use cotton wipe parts.(4) the vacuum system has serious pollution, including containers, pipes and so on. It should be cleaned.(5) the spring of the vane is broken and should be adjusted.

- Q:What do you mean by the self coupling device on the pump?

- Installation of GAK self coupling device:The installation of automatic coupling submersible sewage pump is mainly the installation of coupling device and the lifting of pump. In the pump before the installation of the rings on the chain, and the pump used for lifting.Installation procedure of coupling device:The coupling frame with four bolts fixed on the pump body; the water outlet pipe is fixed on the substrate; positioning cone mounted on the pipe seat; the lower end of the guide pipe is sleeved in the positioning cone, the upper end is sheathed on the guide rod of the rubber block; the guide rod frame is fixed on the pool wall. The function of the rubber block: the axial compression degree of the rubber block is adjusted by the screw on the guide rod frame, so that the diameter of the rubber block is consistent with the inner diameter of the guide rod, and the guide rod is stable.

- Q:What are the failures and causes of the replacement of the fuel pump assembly?

- Common troubles of gasoline pump:Gasoline pump supply shortage of gasoline pump supply depends on the pump membrane stroke, stroke, pump oil should be more; however, the amount of gasoline pump oil pump will reduce the consumption of gasoline engine, and the fuel pump is inevitable, if the engine fuel consumption, but the actual amount of oil is less, this situation is the amount of oil in the petrol pump, there will be a float chamber of a carburetor oil level is reduced, the engine power shortage.

- Q:What is pump suction work?

- Pump is mainly used to transport liquid, including water, oil, acid and alkali liquid, emulsion, suspension emulsion and liquid metal, etc., also can transport liquid, gas mixture and liquid containing suspended solids.

- Q:What is the name of the day pump and ground pump? Specific introduction

- Day pumpDay pump is called "day pump", the main reason is that it can deliver concrete to a certain height, make up for other concrete pump transportation shortage. Compared with other concrete pumps, the pump has its own boom, and the concrete can be transported without the use of artificial cloth. It is very convenient for use. At present, China's longest boom pump is 101 meters, which means that 101 meters under the floor can be completed with the help of day pump concrete delivery. In addition, the pump is equipped with a chassis, so compared with the ground pump, it can walk independently, moving very convenient, you can quickly move from one site to another location.

- Q:Water pump can not be pumped out, how to maintain water?

- Packing overheating:Due to packing too tight, the cooling water can not enter the filler, or the shaft surface damage. Measures for proper relaxation of packing and cleaning of sealing pipe are adopted. Filler wear must be replaced with new ones. Before installation, soak in the oil and rotate it in turn. The incision should be staggered so that water leakage can be reduced. Fill the last lap after installed loading pressed to cover operation for further adjustment of the tightness.

- Q:Why can the centrifugal pump hold down the pressure?

- Centrifugal pumps are vertical, horizontal, single-stage, multi-stage, single suction, double suction, self suction and other forms. Vertical centrifugal pump is referred to as submerged pump, molten salt pump and submerged pump. Centrifugal pumps use the impeller to rotate and cause centrifugal motion of the water to work.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Water Ring Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords