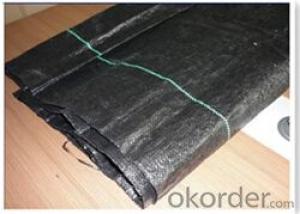

Weed control fabric,textile,geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Weed control fabric,textile,geotextile

1.anti-weed textile,landscape fabric

2.Materials:PP

3.Unit weight:70~200g/m2

4.Width:1 ~4m

Introduction: Plastic woven film yarn geotextile is a kind of geotextile made by extruding, cuting film,stretching to film yarn (monofilament, split-film yarn) ,weaving.

Application:

used in weed control in the garden or agriculture,

also used in dam, tunnel, reservoir, channel and roofing for anti-leakage and scrap yard protection

Technical index of the Plastic woven film yarn geotextile

Item | Index | ||||||

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | |

Breaking strength at warp direction (kN/m) ≥ | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking strength at weft direction (kN/m) ≥ | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation at break (%) ≤ | 28 | ||||||

Trapezoid tearing strength( warp direction ) (kN) ≥ | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

Bursting strength (kN) ≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical permeability coefficient (cm/s) | 10-1~10-4 | ||||||

Effective pore size O95,mm | 0.08~0.5 | ||||||

Mass per unit area (g/m2) | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Mass error in unit area (%) | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 |

- Q:How do plastic nets perform in high-altitude areas?

- Plastic nets perform well in high-altitude areas as they are lightweight, durable, and resistant to extreme weather conditions. They provide effective protection against erosion, wind, and snow, making them suitable for various applications such as slope stabilization and construction projects in mountainous regions.

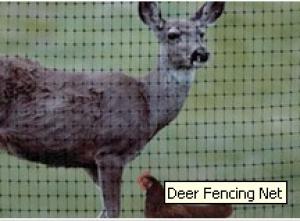

- Q:How do plastic nets affect wildlife?

- Plastic nets can negatively affect wildlife in various ways. They can entangle animals, leading to injuries, suffocation, or even death. Marine animals like turtles, dolphins, and seabirds are particularly vulnerable to becoming entangled in fishing nets or discarded plastic nets, hindering their movement and feeding abilities. Additionally, plastic nets can also disrupt the natural habitats and ecosystems of various species, causing imbalances in the food chain. Overall, plastic nets pose a significant threat to the well-being and survival of wildlife.

- Q:Can plastic nets be used for pond protection?

- Yes, plastic nets can be used for pond protection. They are commonly used to cover ponds and prevent debris, leaves, and animals from entering the water, which helps maintain the pond's cleanliness and protects the aquatic life.

- Q:Are plastic nets resistant to bacterial growth?

- Yes, plastic nets are generally resistant to bacterial growth. The non-porous nature of plastic materials makes it difficult for bacteria to adhere and grow on the surface of plastic nets. Additionally, plastic nets can be easily cleaned and sanitized, further reducing the risk of bacterial growth.

- Q:Can plastic nets be used for creating plant support systems?

- Yes, plastic nets can be used for creating plant support systems.

- Q:Do plastic nets have any electrical conductivity?

- No, plastic nets do not have electrical conductivity.

- Q:Are plastic nets resistant to abrasion?

- Yes, plastic nets are generally resistant to abrasion.

- Q:Can plastic nets be used for privacy screens in residential areas?

- Yes, plastic nets can be used as privacy screens in residential areas. They provide a cost-effective and easy-to-install solution for creating privacy in outdoor spaces such as balconies, patios, and gardens. Plastic nets are lightweight, durable, and often come in various colors and patterns to suit different preferences. They can block unwanted views while still allowing airflow and natural light, making them a popular choice for residential privacy screens.

- Q:How do plastic nets compare to rubber mesh materials?

- Plastic nets and rubber mesh materials have some similarities but also notable differences. Both materials are commonly used for various applications such as packaging, sports equipment, and industrial purposes. Plastic nets are typically made from synthetic polymers like polyethylene or polypropylene, while rubber mesh materials are usually composed of rubber compounds. In terms of strength and durability, plastic nets tend to be more resilient and resistant to wear and tear compared to rubber mesh materials. Plastic nets are also often more lightweight and have higher tensile strength, making them suitable for applications that require higher load-bearing capacity or protection against impact. On the other hand, rubber mesh materials offer greater flexibility and elasticity, allowing them to conform to irregular shapes more easily. Rubber mesh can stretch and bounce back to its original form, making it ideal for applications that require shock absorption or impact resistance, such as protective padding or sports equipment. Additionally, plastic nets are generally more cost-effective and easier to mass-produce compared to rubber mesh materials. Plastic nets can be manufactured in various sizes and configurations, providing versatility and customization options. Rubber mesh materials, however, are usually more expensive and require specialized manufacturing techniques. Ultimately, the choice between plastic nets and rubber mesh materials depends on the specific requirements of the intended application. Factors such as strength, flexibility, cost, and manufacturing feasibility need to be considered to determine the most suitable material for the given purpose.

- Q:How do plastic nets contribute to environmental pollution?

- Plastic nets contribute to environmental pollution primarily because they are not biodegradable and often end up in our oceans, rivers, and landfills. These nets can entangle and harm marine animals, disrupt ecosystems, and take hundreds of years to decompose. Additionally, microplastics can be released from these nets, further contaminating the environment and posing a threat to wildlife and human health.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Weed control fabric,textile,geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords