P5,Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging Detail: | Bundle or Container or as per customers requirement. |

Delivery Detail: | within 25 days after we receive an irrevocable L/Cor 30% deposit |

Specifications

1) ASTM A335 P11 Steel Pipe&Tube

2) Outer Diameter: 10-914mm

3) Wall thickness: 1-100mm

4) Length:3-16m

Cangzhou Qiancheng Steel-Pipe Group Co.(QCCO)

Our products and sizes scope is as following,

SEAMLESS PIPE OD: 3/8"-36"(17.1mm-914.4mm), WT: 2-100mm,

COLD DRAW TUBES OD: 3/8"-3-1/2" (17.1mm-88.9mm),

HOT ROLLES PIPES OD: 4"-8" (114mm-219.1mm),

HOT EXPANSION OD: 10"-36" (273mm-914mm),

LSAW SIZES SCOPE OD: 16” - 56”( 406.4mm-1422mm),WT 8mm-55mm,

OCTG:Seamless and ERW Casing and Tubing OD: 2-3/8" - 20", WT: 3mm-20mm,

Seamless Steel Tubes for Gas Cylinder GB18248

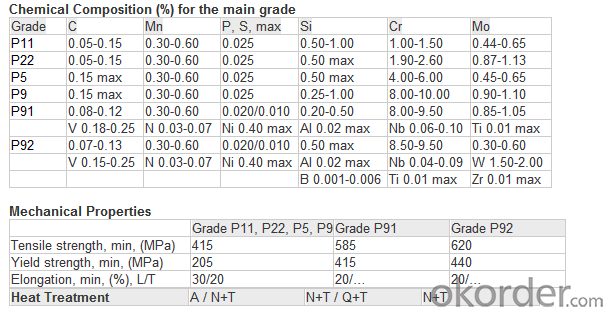

Detailed introduction to ASTM A335 seamless alloy steel pipe:

ASTM A335 seamless alloy steel pipe

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

- Q:Are stainless steel pipes suitable for automotive applications?

- Yes, stainless steel pipes are suitable for automotive applications. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for use in automobile components that are exposed to harsh environments, such as exhaust systems and catalytic converters. Stainless steel pipes offer excellent resistance to heat, chemicals, and abrasion, ensuring long-lasting performance in automotive applications. Additionally, stainless steel is lightweight and has high strength, which contributes to improved fuel efficiency and overall vehicle performance.

- Q:Are stainless steel pipes suitable for architectural applications?

- Yes, stainless steel pipes are highly suitable for architectural applications. They offer excellent durability, corrosion resistance, and aesthetic appeal, making them an ideal choice for various architectural structures such as handrails, facades, and interior designs. Additionally, stainless steel pipes can withstand harsh weather conditions, maintain their appearance over time, and require minimal maintenance, further enhancing their suitability for architectural use.

- Q:Can stainless steel pipes be anodized?

- No, stainless steel pipes cannot be anodized. Anodizing is a process used to create a protective layer on the surface of metals, primarily aluminum. Stainless steel already has a naturally occurring oxide layer that provides corrosion resistance, making anodizing unnecessary.

- Q:Can stainless steel pipes be used for architectural purposes?

- Yes, stainless steel pipes can be used for architectural purposes. Stainless steel has several properties that make it suitable for architectural applications. Firstly, it is highly resistant to corrosion, which is important for structures exposed to the elements. Stainless steel pipes also have a sleek and modern appearance, which can add an aesthetic touch to architectural designs. Additionally, stainless steel is a strong and durable material, providing structural integrity and longevity to buildings. Its versatility allows it to be used in various architectural elements such as handrails, balustrades, staircases, and structural supports. Overall, stainless steel pipes are a popular choice for architectural purposes due to their combination of corrosion resistance, aesthetic appeal, and strength.

- Q:What is the difference between seamless and EFW stainless steel pipes?

- Seamless and EFW stainless steel pipes are distinct types of stainless steel pipes with unique characteristics and manufacturing processes. To begin with, seamless stainless steel pipes are produced without any welding seams or joints. They are formed from a solid cylindrical billet, which is heated and stretched over a mandrel to create a hollow tube. This method guarantees consistent wall thickness and a smooth interior surface, making them ideal for applications requiring high pressure, high temperature, or corrosive environments. Due to their seamless construction, these pipes offer enhanced strength and durability. On the contrary, EFW stainless steel pipes are made by using high-frequency electrical current and pressure to weld the edges of two stainless steel sheets or plates together. This fusion welding process results in a continuous seam running along the length of the pipe. EFW pipes are generally used for lower-pressure and lower-temperature applications, such as conveying fluids or gases in industrial settings. One notable difference between seamless and EFW stainless steel pipes lies in their manufacturing complexity. Seamless pipes necessitate more intricate and precise manufacturing techniques, leading to higher production costs compared to EFW pipes. Additionally, the seamless process allows for a wider range of sizes and thicknesses, whereas EFW pipes are typically limited in their size options. Another distinction lies in the availability of grades and alloys. Seamless stainless steel pipes come in a wide range of grades and alloys, providing greater flexibility for specific applications. In contrast, EFW pipes have a more limited selection of available grades and alloys. Regarding mechanical properties, seamless stainless steel pipes generally exhibit superior strength and corrosion resistance compared to EFW pipes. The absence of welds or joints in seamless pipes reduces the risk of weak points that could be susceptible to corrosion or failure. In conclusion, seamless stainless steel pipes are produced without welding seams, offering improved strength, durability, and corrosion resistance. They are suitable for high-pressure, high-temperature, or corrosive applications. Conversely, EFW stainless steel pipes are created by fusing two stainless steel sheets or plates together, making them more suitable for lower-pressure and lower-temperature applications.

- Q:How do stainless steel pipes compare to titanium pipes?

- Stainless steel pipes and titanium pipes have their own unique characteristics and are used in various applications depending on specific requirements. In terms of strength, titanium pipes are generally stronger than stainless steel pipes. Titanium has a high strength-to-weight ratio, making it ideal for applications that require lightweight but strong materials. Stainless steel, on the other hand, is known for its excellent tensile strength and durability but is relatively heavier compared to titanium. When it comes to corrosion resistance, both stainless steel and titanium pipes are highly resistant to corrosion. However, titanium pipes offer superior corrosion resistance, especially in aggressive environments such as seawater or chemical processing applications. Stainless steel pipes also have good corrosion resistance, but may require additional coatings or treatments to enhance their resistance in certain conditions. Another aspect to consider is the temperature resistance. Titanium pipes can withstand high temperatures without losing their strength or structural integrity, making them suitable for high-temperature applications such as aerospace or power generation industries. Stainless steel pipes also exhibit good heat resistance, but their performance may vary depending on the specific grade of stainless steel and the temperature range involved. Cost is an important factor to consider as well. Stainless steel pipes are generally more cost-effective compared to titanium pipes. Titanium is a more expensive material due to its scarcity, difficult fabrication process, and higher production costs. Therefore, if cost is a significant consideration, stainless steel pipes might be a more viable option. In summary, stainless steel pipes and titanium pipes have their own advantages and are suitable for different applications. Titanium pipes offer superior strength, corrosion resistance, and heat resistance, but come at a higher cost. Stainless steel pipes provide good strength, corrosion resistance, and cost-effectiveness. Ultimately, the choice between the two will depend on the specific requirements, budget, and intended application of the pipes.

- Q:Are stainless steel pipes suitable for power plant systems?

- Stainless steel pipes prove to be a suitable option for power plant systems. Stainless steel is renowned for its exceptional ability to resist corrosion, a critical characteristic required in power plant systems. These systems expose pipes to elevated temperatures, pressures, and various corrosive elements like water, steam, and chemicals. The stainless steel pipes demonstrate remarkable resistance to rust, oxidation, and scaling, ensuring their reliability and durability over extended periods of time in power plant operations. Moreover, the stainless steel pipes possess considerable strength, enabling them to endure the high pressure and stress commonly encountered in power plant systems. Additionally, they exhibit outstanding heat resistance, a crucial feature given the extreme temperatures to which the pipes are exposed in power plants. In summary, due to their corrosion resistance, strength, and heat resistance properties, stainless steel pipes enjoy widespread popularity as a favored choice in power plant systems.

- Q:What is the difference between electropolished and bright annealed stainless steel pipes?

- Two distinct surface treatments are applied to stainless steel pipes in order to enhance their properties and appearance: electropolishing and bright annealing. Electropolishing, an electrochemical process, eliminates a thin layer of material from the stainless steel pipe's surface. This procedure eradicates any impurities, contaminants, or roughness, resulting in a polished and smooth finish. Additionally, electropolishing bolsters the stainless steel's resistance to corrosion by generating a passive oxide layer on the surface, which safeguards the underlying material against corrosion. On the contrary, bright annealing is a heat treatment process involving heating the stainless steel pipe to a precise temperature and gradually cooling it under controlled conditions. This technique alleviates internal stresses, enhances the material's ductility and toughness, and improves its mechanical properties. Bright annealing also produces a smooth and reflective surface finish comparable to electropolishing, but without the electrochemical removal of material. In conclusion, the primary discrepancy between electropolished and bright annealed stainless steel pipes lies in the methods employed to achieve the desired surface finish. Electropolishing entails removing material through an electrochemical process, whereas bright annealing is a heat treatment process that yields a smooth and reflective surface without material removal. Both treatments enhance the appearance and corrosion resistance of stainless steel pipes, but bright annealing also elevates the material's mechanical properties.

- Q:How do you calculate the pipe volume for a specific application?

- To calculate the pipe volume for a specific application, you need to multiply the cross-sectional area of the pipe by its length. The cross-sectional area can be determined by using the formula for the area of a circle (πr^2), where r is the radius of the pipe. Once you have the cross-sectional area, multiply it by the length of the pipe, and you will have the volume.

- Q:Can stainless steel pipes be used for chemical refineries?

- Indeed, chemical refineries can utilize stainless steel pipes. Stainless steel possesses exceptional resistance to corrosion, rendering it an appropriate option for the management of diverse chemicals and corrosive substances prevalent in refineries. It provides exceptional strength, durability, and high temperature resistance, making it an ideal choice for the arduous conditions and demanding settings within chemical refineries. Moreover, stainless steel pipes are effortless to clean and maintain, a critical aspect in industries where cleanliness is of utmost importance to prevent contamination or compromise product quality. In summary, stainless steel pipes are extensively employed in chemical refineries due to their corrosion resistance, strength, and long lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

P5,Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords