High-end Steel Structure Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

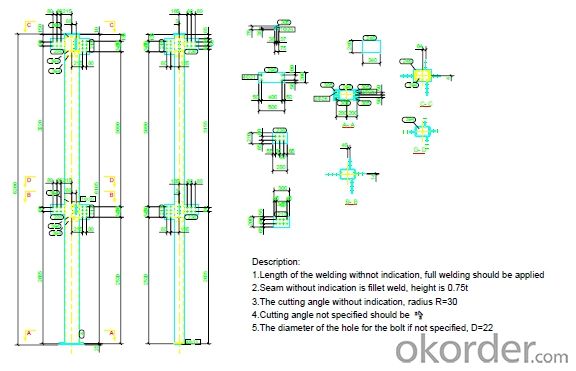

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

The new railway section of bullet train is the inspection and repair base for north China and

the inspection and repair center for the north section of Beijing to Shanghai high-speed

railway. The total area is 183,330 square meters. The steel structure adopt arch steel truss

with maximum span 36 meters.

- Q:How do steel structures perform in terms of energy efficiency?

- Steel structures are known for their excellent energy efficiency. They have a high thermal mass, which means they can effectively absorb and store heat, reducing the need for additional heating or cooling. Additionally, steel structures can be designed with insulation materials to further enhance their energy efficiency. Overall, steel structures are a sustainable choice that can significantly contribute to energy savings.

- Q:How are steel structures used in the construction of observatories?

- Observatories often use steel structures because they are incredibly strong, durable, and versatile. Steel ensures the structural integrity needed to support the observatory's equipment, including telescopes, domes, and scientific instruments. One notable advantage of steel structures is their ability to withstand extreme weather conditions. Many observatories are situated in remote and harsh environments, like mountaintops, where they face strong winds, heavy snow loads, and seismic activity. Steel's high tensile strength and corrosion resistance make it the perfect material for enduring these challenging conditions, ensuring the observatory's safety and stability. Steel structures also allow for spacious areas to accommodate telescopes and equipment. The use of steel beams and columns creates unobstructed views of the sky, minimizing interference with observatory operations. This is crucial for capturing top-quality astronomical data. Moreover, steel structures are highly flexible and can be easily modified or expanded as the observatory's needs change over time. This is especially important for observatories engaged in ongoing research or technological advancements, as they may need to upgrade or replace equipment periodically. Steel structures enable seamless integration of new equipment or expansion without compromising structural integrity. Furthermore, steel is an environmentally friendly and sustainable material. It can be completely recycled, reducing the observatory's carbon footprint during construction. Steel structures also require less maintenance compared to other materials, reducing long-term costs and ensuring the observatory's longevity. In conclusion, steel structures are essential in observatory construction due to their strength, durability, and versatility in supporting equipment and withstanding challenging environmental conditions. Their flexibility, sustainability, and low maintenance requirements make them an ideal choice for observatories requiring long-term reliability and adaptability.

- Q:Ratio of width to thickness in steel structure design,

- The slenderness ratio of columns in the design of components in the main role is to calculate to consider the load bearing capacity of reinforced concrete columns under eccentric compression is long, due to the impact of additional eccentric component elastic-plastic deformation caused by the eccentricity, stability coefficient and coefficient of axial compression member, and the slenderness ratio.The columns are also divided into short columns, long columns and slender columns due to slenderness. From here we determine the type of column and, in practice, try to avoid slender columns

- Q:What are the advantages of steel structure houses?

- Because of its advantages of light weight, good seismic performance, short construction period, green and pollution-free, the steel structure system has been widely used in the field of construction. The strengthening of the national economic strength and the requirements of commercialization and industrialization of the housing have promoted the steel structure to be the most suitable structural system in the construction house.

- Q:What are the design considerations for steel agricultural buildings?

- Some design considerations for steel agricultural buildings include ensuring proper ventilation and natural lighting, incorporating flexible layouts to accommodate various farming activities, incorporating insulation for temperature control, and designing for durability and resistance to weather conditions. Additionally, considerations for easy maintenance, efficient use of space, and compliance with local building codes and regulations are also important.

- Q:How are steel structures used in sports training facilities?

- Steel structures are commonly used in sports training facilities due to their durability, strength, and versatility. They provide the necessary support for large open spaces, such as indoor stadiums, training halls, and gyms. Steel beams and columns are used to create the framework for these structures, allowing for the construction of high ceilings and wide spans without the need for excessive columns or walls. This enables athletes to train in spacious environments, accommodating various sports activities and equipment. Additionally, steel structures can be easily customized and modified to meet specific training requirements, making them ideal for sports facilities that need to adapt to changing needs over time.

- Q:What is the process of demolishing a steel structure?

- The process of demolishing a steel structure typically involves several key steps. First, a thorough assessment is conducted to determine the structural integrity, potential hazards, and the most appropriate demolition methods. Next, any hazardous materials such as asbestos are safely removed. Then, the steel structure is systematically dismantled, starting from the top and working downwards. Various methods like cutting, shearing, or using heavy machinery like cranes and bulldozers may be employed to bring down the structure. Finally, the steel debris is sorted, recycled, and disposed of properly, adhering to environmental regulations.

- Q:How are steel structures tested for structural integrity?

- Steel structures are tested for structural integrity through a combination of non-destructive testing methods, such as visual inspections, ultrasonic testing, magnetic particle testing, and liquid penetrant testing. These techniques help identify any potential defects or weaknesses in the steel components that could compromise the overall structural stability. Additionally, load testing is conducted to simulate real-life conditions and ensure that the structure can withstand the expected loads and stresses it will be subjected to.

- Q:What are the factors that affect the construction schedule of a steel structure?

- Several factors can affect the construction schedule of a steel structure. Some key factors include the complexity and size of the project, availability of materials and labor, weather conditions, site conditions and accessibility, design changes or modifications, and any unforeseen challenges or delays encountered during the construction process. Proper planning, coordination, and proactive management of these factors are crucial to ensure the timely completion of the steel structure.

- Q:How are steel structures used in the construction of distribution centers?

- Distribution centers rely heavily on steel structures for their construction due to the numerous advantages they offer. Firstly, steel structures are renowned for their durability, strength, and cost-effectiveness, making them an ideal choice for these facilities. One major benefit of steel structures is their ability to bear heavy loads. Given the substantial quantities of goods handled by distribution centers, robust support systems are essential. Steel beams and columns can withstand significant weight, allowing for the creation of spacious storage areas and high ceilings that maximize storage capacity. Moreover, steel structures possess excellent resistance to environmental factors such as fire, moisture, and pests. This is particularly crucial in distribution centers, where the safety and protection of goods are of utmost importance. Steel's inherent fire-resistant properties help prevent the spread of fires and minimize damage. Additionally, steel structures offer flexibility in design and construction. Distribution centers often require customization to meet specific operational needs, such as tall racking systems, mezzanine floors, and conveyor systems. Steel's versatility allows for easy modification and expansion of the facility as business needs evolve. Furthermore, steel construction is relatively faster compared to traditional building materials. The use of pre-engineered components enables off-site fabrication, reducing construction time and ensuring quicker project completion. This advantage is particularly significant for distribution centers that face tight deadlines and must commence operations promptly. Lastly, steel structures provide cost savings over the lifespan of a distribution center. Although the initial investment in steel construction may be higher than other materials, the long-term benefits outweigh the costs. Steel's durability and low-maintenance requirements result in reduced repair and replacement expenses over time. Additionally, steel is recyclable, making it an environmentally-friendly option. In conclusion, the strength, durability, flexibility, and cost-effectiveness of steel structures make them indispensable in the construction of distribution centers. They provide the necessary support for heavy loads, resistance to environmental factors, customization options, and faster construction. Ultimately, steel structures contribute to the efficient and reliable operation of distribution centers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-end Steel Structure Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords