GI , GL, CR and Corrugated steel sheet, Color steel laminboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy),with pallet |

| Delivery Detail: | 20-25 days after receiving the deposit |

Specifications

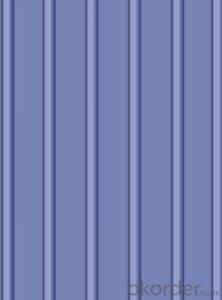

PPGI, PPGL , GI , GL, CR and Corrugated steel sheet

thickness : 0.12mm to 1.2mm,

width :600mm to 1500mm

zinc coat:30-275g

We can offer PPGI and GI in thickness available from 0.12mm to 1.2mm, width available from 600mm to 1500mm

Basic information

1: Size: 0.15-1.2mm*600-1250mm

2: Paint: Top side: 15-25um, Back side: 5-9um, or according to customer’s order.

3: Base material: Hot dipped galvanized steel coil, GL

4: Zinc coating: 30-275g.

5: Coil weight: 3-6tons

6: Coil ID: 508mm

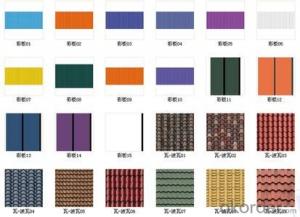

7: Color: Any color.

8: Standard: ASTM, GB, JIS

9:Grade: CGCC,CGCH,SGCC, DX51D and ASTM

10:Surface Treatments: skin passed, chromated, oiled and antifinger

11: Approved Certificate: SGS / ISO9001 / BV

12: Package Method: Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy)

13: Payments terms: T/T ,L/C,etc.

Brief Introductionof product

1. Color Coated steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Color Coated Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color Coated Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Color Coated Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Color Coated Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

SGLCC | 140-350 | 270-500 | 22 |

SGLCD | 140-300 | 270-420 | 26 |

SGLCDD | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q:Air conditioning year after the addition of Calvary is not the reason for refrigeration

- The system after spraying the rigid foam polyurethane insulation layer in the wall to form a continuous seamless overall, winter can avoid the heat bridge, greatly reduce the indoor heat loss; summer can greatly reduce the sun due to the external walls of the heat conduction, and then So that heating, air conditioning, energy consumption, energy saving effect is obvious, can reduce energy consumption, protect the theme structure, to extend the life of the building

- Q:Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. Sandwich panels are a type of construction material that consists of two outer layers (usually made of metal) with an insulating core in between. This combination of materials provides excellent thermal insulation, fire resistance, and soundproofing properties, making them ideal for train station applications. The insulation properties of sandwich panels help to regulate the temperature inside the train station, ensuring a comfortable environment for passengers and staff regardless of external weather conditions. This can help reduce energy consumption and lower heating or cooling costs. Sandwich panels are also highly fire-resistant, which is crucial for train stations where the risk of fire is a major concern due to the presence of electrical systems, passengers, and potentially flammable materials. The fire-resistant properties of sandwich panels can help contain and slow down the spread of fire, providing valuable time for evacuation and firefighting efforts. Furthermore, sandwich panels offer excellent soundproofing capabilities. Train stations are typically noisy environments due to the constant movement of trains, announcements, and passenger conversations. The use of sandwich panels can significantly reduce noise transmission, creating a more peaceful and comfortable atmosphere for passengers and staff. Additionally, sandwich panels are lightweight and easy to install, making them a cost-effective and efficient choice for train station construction or renovation projects. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are indeed suitable for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, providing a positive experience for both passengers and staff.

- Q:3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- I have a veteran to sell, because I just bought a new Taiwan, the price of ..

- Q:Steel structure workshop roof load is the number of specific Please thank you

- General color steel foam sandwich panels. Price in the 45 - 60 yuan / M ? or so.

- Q:Sandwich panels and Malacca ecological board what is the difference

- You can use the shear wall, and then hollow insulation can reduce the noise, but the cost of high

- Q:Similar to the color steel tile, floor board, the roof of the push is how much ah

- General wallpaper glue is sticky, you can consider using white latex to try.

- Q:Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q:Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q:Color steel sandwich board on the price of how much?

- Due to the level of restrictions, there must be inappropriate, hope to add to the same channel or finger scaffolding erection of quality requirements and safety requirements should be organically unified to ensure that the erection process and the subsequent use and removal process of safety and application

- Q:What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GI , GL, CR and Corrugated steel sheet, Color steel laminboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords