High Quality Construction Material laminboard

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 1,Each bare coil to be securely tied with two bands through the eye of coil (or not) and one circumferential. 2,the contact points of these bands on the coil edge to be protect with edge protectors. 3,Coil then to be properly wrapped with water proof /resistant paper, it then to be properly and completely metal wrapped. 4,Wooden and iron pallet can be used or as your requirements. |

| Delivery Detail: | 7-30 days |

Specifications

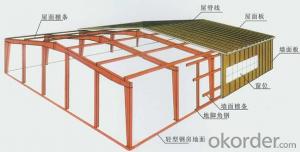

laminboard

1.Technique: Cold Rolled

2.Width: 40-1250mm

3.Thickness:0.18-2mm

4.Color:all RAL color

NAME | laminboard |

Other Names | Color Coated Steel Plate |

Materials | Hot Galvanised Steel |

Place of Origin | China (Mainland) |

Grade Standard | National Standard Grade |

Type | 950 960 1150 |

Appearance | Any Color With ribbed |

Application | For wall or roof building |

Brand Name | CAMELSTEEL |

Thickness | 0.18mm-2mm |

Width | 600 mm-1150mm |

Length | as your requirement |

Advantages

1)Lower Price and Best Price

2)Waterproof and Fireproof

3)The advantage of the rock wool sandwich wall panel

4)High Strength

5)Durable

6) Heat insulation and Sound insulation

7) Energy-saving and Most area-saving

8)Environmental protection

Specifications

1.Base mental: hot galvanized steel

2.Thickness: 0.18mm-2.0mm

3.Width: 40mm-1250mm

4.Color: all RAL color(standard international color)

5.Zinc-coating: 40g-275g

6.Packing: standard export package

7.Painting: Top and bottom:20mic+5mic Back:6mic-8mic

8.Tolerance: Thickness: +/-0.02mm Width: +/-0.02mm

9.The special order can be negotiated oils

10.Welcome to send inquiry to us freely, hoping we could build a long-term cooperation in the future.

- Q:Are sandwich panels suitable for food kiosks?

- Sandwich panels are indeed appropriate for food kiosks. They have gained significant popularity in the construction industry due to their durability, insulation properties, and ease of installation. These panels consist of two external layers, typically constructed from metal, and a core material, such as polyurethane foam or rockwool, which offers outstanding thermal insulation. To meet food safety regulations, food kiosks necessitate a hygienic and clean atmosphere. Sandwich panels provide a smooth, non-porous surface that is simple to clean and maintain, making them an ideal choice for food kiosks. Furthermore, these panels offer thermal insulation, helping to maintain the appropriate temperature for storing and serving food, regardless of the climate. In addition, sandwich panels are lightweight, facilitating effortless transportation and assembly. This allows for quick setup and relocation if necessary. Moreover, they possess remarkable structural strength, ensuring stability and security for the kiosk. All in all, due to their durability, insulation properties, hygienic surfaces, and ease of installation, sandwich panels are a suitable option for food kiosks.

- Q:Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q:Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

- Q:What are the different types and uses of clean color steel plates?

- Playing glass glue, with a little better quality.

- Q:Sandwich panels and Malacca ecological board what is the difference

- Not count But it is best to mark the gun in the obvious place.

- Q:How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q:What is the weight per unit area of 100 thick rock wool sandwich panels?

- First, the electricity management: ⒈ temporary electricity must be "" construction site temporary electricity safety technical specifications "JGJ46-88" compilation of electricity construction organization design and development of safe electricity technical measures and electrical fire protection measures. ⒉ temporary electricity engineering drawings must be drawn solely by the electrical engineering and technical personnel, after the approval of the technical person as a temporary basis for construction. ⒊ temporary electricity construction organization design content and steps: ⑴ site exploration, to determine the power line into the total distribution box (cabinet), the distribution of electrical box location and line direction. ⑵ load calculation, select the wire cross-section and electrical type, specifications. ⑶ draw electrical plan, elevation and wiring system diagram.

- Q:Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- Wood insulation effect can be, the smaller the density the better insulation, asbestos or glass wool will be better, but the price of your Kazakhstan

- Q:Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Clamp material, and pressure ah, a little bit of deformation of the clamp will lead to the next time the use of water leakage; some clamp is sealed with rubber ring, pressure, the rubber ring is not fully restored, will lead to Leakage of water; some cases in the pressure, the pipeline to the development of the process of training, but also lead to tight hoop tightly

- Q:What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Construction Material laminboard

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords