Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Main Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

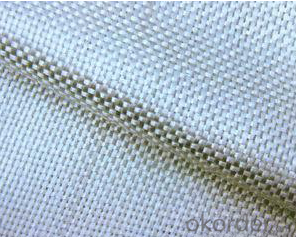

Weave:Plain,Twill,Satin,Multiaxial,UD

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:Can fiberglass fabric be used for making shower curtains?

- Absolutely! When it comes to making shower curtains, fiberglass fabric is a stellar choice. Renowned for its durability, water resistance, and effortless upkeep, it's an ideal material. This fabric resists mildew and mold, which are frequent concerns in bathrooms, and can withstand the moisture and humidity found in shower areas. What's more, fiberglass fabric is a breeze to clean and doesn't absorb water, preventing saturation or unpleasant odors. All in all, opting for fiberglass fabric to create shower curtains ensures a lasting and hygienic solution for any bathroom.

- Q:What are the different fiberglass fabric finishes for abrasion resistance?

- There are several different fiberglass fabric finishes that enhance abrasion resistance, including silicone, PTFE (Teflon), acrylic, and neoprene. Each of these finishes provides varying levels of protection against wear and tear, making fiberglass fabrics suitable for a wide range of applications requiring durability and longevity.

- Q:Can fiberglass fabric be used for making wall coverings?

- Yes, fiberglass fabric can be used for making wall coverings. Fiberglass fabric is a versatile material that offers numerous benefits for wall coverings. It is highly durable and resistant to wear and tear, making it a long-lasting option for covering walls. Additionally, fiberglass fabric is fire-resistant, making it a safe choice for wall coverings. It can also be easily customized to fit any wall size or shape, providing a seamless and professional finish. Furthermore, fiberglass fabric is available in a wide range of colors, textures, and patterns, allowing for endless design possibilities. Overall, fiberglass fabric is a practical and stylish choice for wall coverings.

- Q:What are the different widths available for fiberglass fabric rolls?

- Fiberglass fabric rolls typically come in various widths to accommodate different applications and preferences. The available widths can vary depending on the manufacturer, but some common options include 1 inch, 2 inches, 3 inches, 4 inches, 6 inches, 12 inches, and 24 inches. These widths are designed to provide flexibility and versatility for a range of projects, from small repairs and patching to larger-scale applications such as boat construction or automotive repairs. It is important to check with the specific supplier or manufacturer to determine the exact widths available for fiberglass fabric rolls, as they may offer additional or customized options to cater to specific needs.

- Q:Can fiberglass fabrics be used for waterproofing?

- Indeed, waterproofing can be achieved with the utilization of fiberglass fabrics. Renowned for its exceptional water-resistant properties, fiberglass is a versatile substance extensively employed in numerous sectors, such as construction and marine industries. By adopting the fabric form, fiberglass can undergo a coating process with waterproof substances like silicone or polyurethane, thereby augmenting its waterproofing capabilities. These coatings establish a formidable barrier that effectively repels water, rendering fiberglass fabrics an optimal choice for waterproofing endeavors. Moreover, the resistance of fiberglass fabrics to mildew and rot further bolsters their appropriateness for waterproofing applications.

- Q:Can fiberglass fabric be used for making sails or kites?

- Fiberglass fabric is suitable for the production of sails and kites, as it is a lightweight and durable material commonly utilized in various industries such as marine and aerospace. Its exceptional strength and ability to resist tearing and stretching make it an excellent choice for constructing sails and kites. Furthermore, the water-resistant properties of fiberglass fabric are essential for sails that will be exposed to moisture. The flexibility of fiberglass fabric also enables it to be molded and shaped into the desired form, making it perfect for creating the aerodynamic shapes necessary for sails and kites. In conclusion, the strength, durability, water resistance, and flexibility of fiberglass fabric make it a suitable material for the fabrication of sails and kites.

- Q:Can fiberglass fabric be used for making industrial curtains?

- Yes, fiberglass fabric can be used for making industrial curtains. Fiberglass is a strong and durable material that is resistant to heat, chemicals, and abrasion. It is commonly used in industrial applications where protection and safety are paramount, such as in manufacturing plants, warehouses, and construction sites. Fiberglass fabric has excellent insulation properties, making it ideal for creating curtains that can control temperature and reduce energy costs. Additionally, it is lightweight and flexible, allowing for easy installation and maintenance. Overall, fiberglass fabric is a suitable choice for making industrial curtains due to its strength, durability, and insulation capabilities.

- Q:Can fiberglass fabric be used in corrosive environments?

- Yes, fiberglass fabric can be used in corrosive environments. It is resistant to many common chemicals and acids, making it suitable for applications in corrosive environments where metal materials would corrode or degrade.

- Q:Is fiberglass fabric resistant to insects?

- Yes, fiberglass fabric is generally resistant to insects. Fiberglass is made from woven strands of glass fibers, which insects are not attracted to or able to consume. Additionally, fiberglass fabric does not provide a suitable environment for insects to nest or breed, as it is non-porous and does not retain moisture. This makes it a popular choice for insect screens and protective covers, as it effectively keeps insects out without the need for chemical insecticides. However, it is important to note that while fiberglass fabric itself is resistant to insects, the seams and openings in the fabric may still allow insects to enter. Therefore, proper installation and maintenance are necessary to ensure complete insect resistance.

- Q:What industries commonly use fiberglass fabrics?

- Fiberglass fabrics are commonly used in a variety of industries due to their exceptional properties and versatility. Some of the industries that commonly use fiberglass fabrics include: 1. Automotive industry: Fiberglass fabrics are extensively used in the automotive sector for the manufacturing of various components, such as car bodies, bumpers, hoods, and interior parts. The lightweight and high strength-to-weight ratio of fiberglass fabrics make them ideal for improving fuel efficiency and overall performance while ensuring durability. 2. Aerospace industry: Fiberglass fabrics find numerous applications in the aerospace industry, especially in the production of aircraft components. They are used in the construction of wings, fuselages, rotor blades, and other structural elements. The high strength, resistance to extreme temperatures, and low weight of fiberglass fabrics make them suitable for aerospace applications. 3. Construction industry: Fiberglass fabrics are widely utilized in the construction sector for reinforcing concrete structures. They are commonly used in the form of fiberglass-reinforced polymers (FRP) to enhance the strength, durability, and crack resistance of concrete elements like beams, columns, and slabs. Additionally, fiberglass fabrics are employed in roofing materials, insulation, and as a reinforcement in wallboards. 4. Marine industry: Due to their excellent resistance to corrosion, water, and UV rays, fiberglass fabrics are extensively used in the marine industry. They are employed for manufacturing boat hulls, decks, and other structural parts. Fiberglass fabrics provide lightweight yet robust solutions, making them highly suitable for various marine applications. 5. Sports and recreation industry: Many sports and recreational equipment manufacturers utilize fiberglass fabrics for their products. Fiberglass fabrics are commonly used in the production of sporting goods such as surfboards, kayaks, paddleboards, and skis. Their strength, flexibility, and resistance to impact make fiberglass fabrics a popular choice in this industry. 6. Chemical and industrial applications: Fiberglass fabrics are highly resistant to chemicals, making them essential in industries dealing with corrosive substances. They are used in the production of chemical storage tanks, pipes, and ducts. Additionally, fiberglass fabrics are utilized for insulation in thermal and electrical applications, such as electronic equipment and furnaces. Overall, fiberglass fabrics have a wide range of applications across various industries due to their remarkable properties. Their high strength, lightweight nature, resistance to corrosion, and versatility make them a preferred material for countless industrial and commercial applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords