Aluminum-frame table Formwork System and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Aluminum-frame table Formwork System and Scaffolding System

Aluminum Form Work Systems are the type of formworks that are manufactured using light weight aluminum. These products are widely appreciated in the market for its sturdiness and durability. This formwork offers one time pouring as the forming is done very quickly. This formwork is made up of aluminum metal frame that provides very sturdy and durable mold for pouring concrete. These are extensively used as concrete frame and cast in -situ concrete j heavy shuttering system. Aluminum formwork owing to its light weight helps to form better quality frameworks. It provides excellent slot arrangement that provides speedy and accurate adjustment in any direction. This can be constructed in very less time reducing labor costs. Aluminum formwork is constructed by using is special high strength aluminum alloy extrusions and 4 mm thick sheets as per the exact specification. Forms are easily and quickly assembled to a desirable shape and thus it is very helpful for rapid paced building construction. With their strong strength, these formworks are very suitable for reinforced concrete construction of multi- storey construction projects. We offer the products at the reasonable prices. The product under this range is Aluminum Form Work Systems.

2. Main Features of Aluminum-frame table Formwork System and Scaffolding System

◆ The complete formwork system for slab casting, easy & quick assembly.

◆ The panel can be supported by both props and scaffolding.

◆ High standardization with components.

◆ Light panel weight, easy to carry.

◆ Economical, versatile & hi-speed formwork system; comes with a permissible slab thickness of 400 mm.

◆ Working efficiency is greatly improved by fast erection and dismantlement.

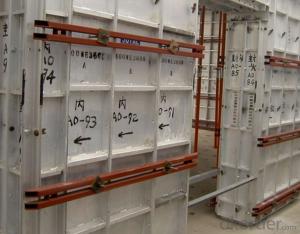

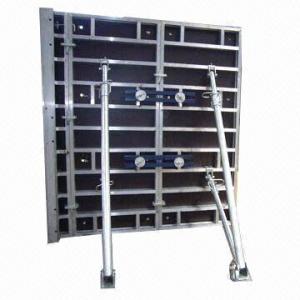

3. Aluminum-frame table Formwork System and Scaffolding System Images

4. Aluminum-frame table Formwork System and Scaffolding System Specification

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

5. FAQ of Aluminum-frame table Formwork System and Scaffolding System

1) What can we do for you?

.We can ensure the quality of the Aluminum-frame table Formwork System and Scaffolding System and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Aluminum-frame table Formwork System and Scaffolding System, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Aluminum-Frame Formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Aluminum-frame table Formwork System and Scaffolding System, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:Case Study of Aluminum Alloy Formwork

- For example: the beam section of the project is larger, the design of the beam at the end of the support with double column support, pole spacing 1200mm, beam at the end of the plate, the beam at the end of support aluminum beam 125mm wide, arranged on both sides of the beam at the end. Aluminum sheet 4mm thick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum-frame table Formwork System and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords