New fireproof aluminum ceiling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Function: | Feature: | |||

| Ceiling Tile Shape: | Ceiling Tile Type: | Surface Treatment: | |||

| Metal Ceiling Material: | Key word: | Specification: | |||

| Height: | Thickness: | Perforated diameter: | |||

| Color: | MOQ: | Delivery time: | |||

| Packing: | Certificate: |

Specifications

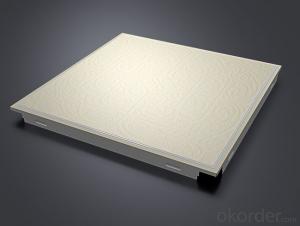

2014 New fireproof aluminum ceiling

Specification:600*600

Material: Aluminum alloy

Certification:ISO,BV, TUV

Factory price

2014 New fireproof aluminum ceiling

1) Our clip in aluminum ceiling:

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

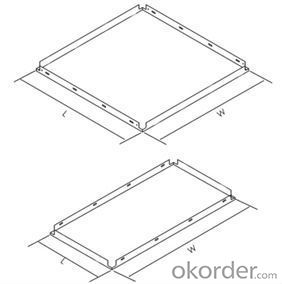

2) Specifications:

| Specification | Thickness | Height | Legend |

| 300×300mm | 0.4-1.0mm | 19mm(short edge) 25mm(High edge) |  |

| 300×450mm | |||

| 300×600mm | |||

| 300×1200mm | |||

| 400×400mm | 0.5-1.2mm | ||

| 500×500mm | |||

| 600×600mm | |||

| 600×1200mm | |||

| Base materials | Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available | ||

| Surface treatment | Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated | ||

| Type of Surface | Plain plate or perforated plate is selected according to the actual requirements | ||

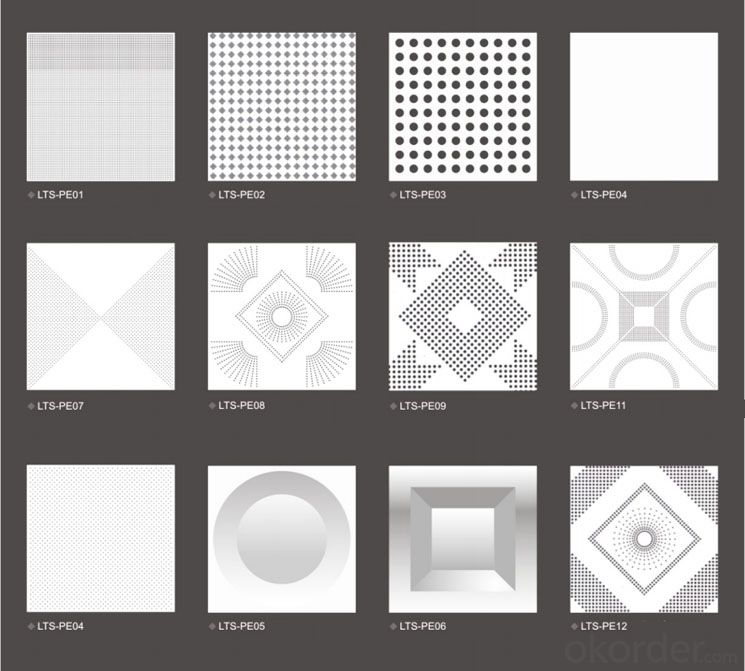

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

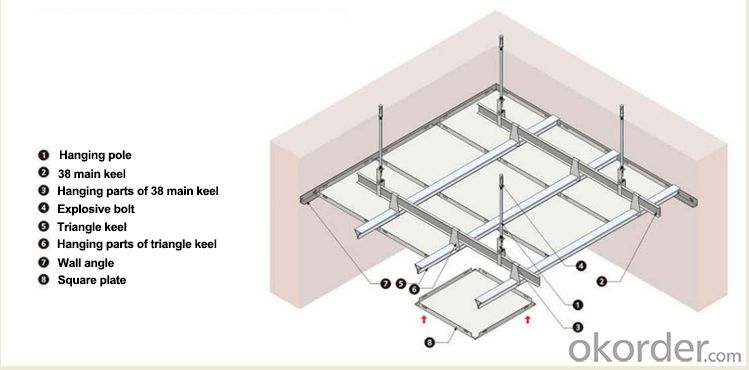

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

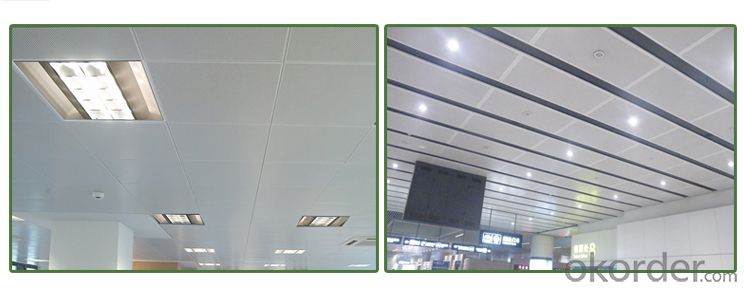

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

- Q:Integrated ceiling aluminum slab board know how much knowledge?

- According to the source of the surface film can be divided into: domestic pearl lamination aluminum plate, imported pearl lamination aluminum plate, LG pearl coated aluminum slab plate (covered with aluminum slab plate in turn Future service life and performance and gradually increased)

- Q:0.6 mm aluminum buckle plate is multiple

- Equal to 12.2 kg weight of a board.

- Q:I do the aluminum slab plate integrated ceiling, drying rack above the flower drum top should be what glue

- It is best to punch as some durable, with a long time is not very good glue ????? Integrated ceiling is a combination of metal square board and electrical appliances, sub-lighting module, heating module, ventilation module. With the installation is simple, easy maintenance, flexible layout, a bathroom, kitchen ceiling of the mainstream. In order to change the monotonous lack of ceiling color, integrated art ceilings are becoming the market trendy.

- Q:How the kitchen ceiling is blackened

- First shovel the original wall paint, and then re-scraping putty, putty scraping twice, sandpaper playing sand, and then paint. Dew paint the reasons there may be two: 1. The original bottom of the putty did not scratch, there may be cut corners; 2. Kitchen water vapor and hot air caused by changes in temperature. If the kitchen is high, it is recommended to make an aluminum slab ceiling, clean and convenient and durable.

- Q:600 × 600 aluminum slab plate production equipment how much money

- The price may be different in general are used in public places ... ... home decoration without the price in addition to the brand and pattern outside ... ... the most important is to see the thickness of 0.45mm-1mm have 9 yuan -20 yuan / piece about 1mm above are 30 yuan / piece above the 600 * 600 specifications, each square needs 2.78 sheets, for example: 10 square, then 10 square * 2.78 = 28 (27.8) Zhang also keel and other accessories

- Q:What is the difference between a grid ceiling and an aluminum slab plate ceiling? Please all of you

- Grille ceiling no panel, only hanging tendons, light steel keel, grille keel no panel, and aluminum slab ceiling by the hanging steel keel aluminum buckle plate composition!

- Q:How to buy aluminum buckle board can save money

- Material To know how to identify the quality of aluminum cords hanging ceiling, the main thing is to understand the ceiling plate material. Aluminum plate material is basically aluminum alloy, the current surface of the ceiling kitchen and bathroom mainly by the titanium alloy, aluminum and manganese alloy and aluminum-magnesium alloy. The greatest advantage of using aluminum-magnesium alloy is the strong antioxidant capacity and durability. While the strength and steel grade of aluminum-manganese alloy are better than aluminum-magnesium alloy, but the antioxidant capacity is lower than that of aluminum-magnesium alloy. Ordinary aluminum alloy materials due to magnesium, manganese content less, strength, steel and antioxidant capacity are weaker than the previous two. Now the market is the most common aluminum-magnesium alloy plate, which has a bright color, anti-oxidation, light weight, high flatness advantages. Determine the merits of aluminum plate material, you can see the elasticity of the aluminum plate. Choose a model, hand it bent, it is easy to be bent and will not restore the original shape, indicating that the aluminum material is not good. After being bent there will be a certain degree of rebound, indicating a good texture of aluminum.

- Q:Exhibition hall ceiling aluminum grid 3d is how to do

- In fact, with the other curtain wall concealed works the same practice, concealed works will be closed after the invisible place to the supervision and acceptance, and confirmed on the acceptance can be, the glass curtain wall is basically covered by the part of the hidden layer of the hidden , The information around the electronic dog has.

- Q:Ceiling ceiling aluminum grille with a long time how to clean

- Pour half pot of warm water to the amount of detergent and then add point Mr. Wei Meng in addition to oil, put the towel in the water. Slightly wring dry and then wipe it.

- Q:What is the difference between aluminum-plastic and aluminum-plated boards?

- Aluminum plate: aluminum alloy plate as the raw material of the ceiling material, generally aluminum-magnesium alloy; from the shape points can be divided into square plate and bar plate two categories, from the surface treatment process can be divided into spray board, Peritoneal plate, roller plate, which, the peritoneal plate to a higher cost and easy to clean, anti-discoloration of the advantages of home improvement. Rolling plate is higher, but the production of sophisticated roller coating in the anti-discoloration, the use of persistence, etc., even better, most of the requirements for the airport hall and other places higher, recently, part of the home improvement High-end brands have begun to roll coating process for home improvement production. Aluminum-plastic plate: the plastic surface is coated with a thin layer of aluminum, aluminum plate that most of the use of roller coating process, according to the thickness of aluminum different price differences, in general, more than 12s of aluminum-plastic plate is more suitable for home improvement Use, too thin will affect the service life. Aluminum-plastic plate can be used for kitchen and toilet ceiling, but requires the substrate of the wood keel and wood to do a strict waterproof treatment, otherwise it will rot. Relative to this problem, the aluminum plate in the installation process does not require the use of any wood, more suitable for the damp environment of the ceiling. In addition: the cost of materials, the aluminum plate is slightly higher than the aluminum plate, but the comprehensive accessories, artificial and other costs, the cost of aluminum slab plate is higher than the aluminum plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New fireproof aluminum ceiling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords