Trustable Cuplock Scaffolding System with Best Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Ring-lock Scaffolding

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2.Main Features of Cup-lock Scaffolding

Each Cup-lock is welded on post every 0.6m. Choose step pitch based on mechanical requirementsWhen installing the scaffolding, insert ledger connector into the pole of the cup-lock, then hammer ledger connector to finish fastening.The more load, the more reliable fasten.Cup-lock Scaffolding has no special retaining member and no active parts. It’s easy and convenient to operation with integral low costs.

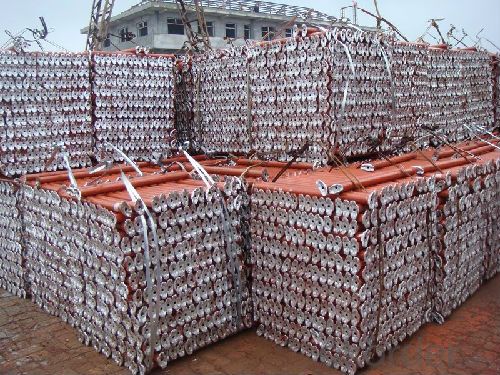

3.Cup-lock Scaffolding Images

4.Cup-lock Scaffolding Specification

A support system for construction, owns advantages of both cup-lock scaffolding and shoring tower.It is in the development direction of new type scaffolding.

It is widely used in buildings, bridges, tunnels etc.

5.FAQ OF Cup-lock Scaffolding

What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we

are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Ring-lock Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:Are there any alternatives to steel tube couplers in scaffolding?

- Indeed, scaffolding offers various alternatives to steel tube couplers. One option entails the utilization of aluminum tube couplers. Made from lightweight and durable aluminum, these couplers offer comparable strength and functionality to steel. They tend to be preferred in scenarios where weight is a concern or where frequent assembly and disassembly of the scaffolding is necessary. Another alternative involves the adoption of plastic tube couplers. These lightweight couplers are easy to handle and resistant to corrosion. They find common use in industries that require non-conductive scaffolding, such as electrical work or environments with high voltage. Furthermore, specialized couplers are also available for specific scaffolding applications. Swivel couplers enable adjustable angles between tubes, sleeve couplers connect two tubes end-to-end, and putlog couplers link tubes to ledger beams. In summary, although steel tube couplers are widely utilized in scaffolding, alternative materials and designs exist that offer similar functionality and cater to specific requirements. It is crucial to take into account the specific needs of the project and seek advice from scaffolding experts to determine the most suitable alternative for the job.

- Q:Can steel tube couplers be used in high-load scaffolding applications?

- Yes, steel tube couplers can be used in high-load scaffolding applications. Steel tube couplers are strong and durable, making them suitable for supporting heavy loads in scaffolding structures. They provide a secure and reliable connection between steel tubes, ensuring the stability and safety of the scaffolding system even under high loads.

- Q:My mom is making me choose between and industrial/ scaffold ear piercing or a six pack of colored contacts?

- I'd go with the piercing. Colored contacts for no reason look fake and are are really stupid I think.

- Q:Do steel tube couplers require any special maintenance or care?

- Yes, steel tube couplers do require some special maintenance and care to ensure their proper functioning and longevity. Regular inspections should be performed to check for any signs of wear, corrosion, or damage. If any issues are identified, immediate action should be taken to repair or replace the coupler. Additionally, it is crucial to keep the couplers clean and free from dirt, debris, or any other substances that can cause corrosion or hinder their performance. Regular cleaning with a mild detergent and water solution can help remove any buildup and maintain the couplers in good condition. Furthermore, the couplers should be stored in a dry and protected environment to prevent exposure to moisture or extreme temperatures, which can lead to rust or other forms of damage. It is advisable to keep the couplers covered or stored in a sealed container when not in use. Proper handling and usage are also essential to ensure the longevity of steel tube couplers. Avoid excessive force or rough handling during installation or removal, as this can cause damage to the couplers. It is recommended to follow the manufacturer's instructions and guidelines for the specific coupler model to ensure proper use and maintenance. In summary, steel tube couplers require regular inspections, cleaning, and proper storage to maintain their performance and durability. Following these maintenance practices will help extend the lifespan of the couplers and ensure their safe and efficient operation.

- Q:What are the requirements of the fastener scaffolding specification?

- Its main features, first of all is simplicity in the production of the concept is relatively simple, but also in terms of the structure is relatively simple, in the production can be a good self-designed There is also a feature that is flexible in the design of the variability, its changes in the production process is inevitable Another feature is the scalability, which can be extended in the design of a single shot of the toilet can be very beautiful, and increase the use of different production methods or different stations Flexible tube in the flexibility is also very good, and its production process has been constantly adjusted in the construction can be adapted to different changes in the field of the process FRP composite pipe is an ideal alternative to stainless steel pipe, the appearance of color is also relatively different The company specializes in:

- Q:What is the typical lifespan of steel tube couplers?

- The typical lifespan of steel tube couplers can vary depending on several factors such as usage conditions, maintenance, and quality of the couplers. However, with proper care and regular inspections, steel tube couplers can have a lifespan ranging from 10 to 20 years or even longer.

- Q:Can steel tube couplers be used in scaffolding projects with limited ground anchoring options?

- Yes, steel tube couplers can be used in scaffolding projects with limited ground anchoring options. Steel tube couplers are designed to join scaffold tubes together securely, providing a strong and stable structure. In situations where ground anchoring options are limited, steel tube couplers offer a reliable alternative for creating a safe scaffolding system. Steel tube couplers are typically manufactured from high-quality steel, ensuring durability and strength. They are designed to withstand heavy loads and provide a secure connection between scaffold tubes. This makes them suitable for use in scaffolding projects where ground anchoring options may not be available or feasible. Additionally, steel tube couplers offer flexibility in scaffolding design and assembly. They can be used to create various configurations and adapt to different project requirements. This adaptability allows scaffolding to be constructed in areas where traditional ground anchoring methods, such as base plates or anchors, may not be possible. However, it is important to note that the use of steel tube couplers in scaffolding projects with limited ground anchoring options should be done in accordance with relevant safety regulations and guidelines. Proper planning, design, and installation are crucial to ensure the stability and safety of the scaffold structure. In summary, steel tube couplers can be effectively used in scaffolding projects with limited ground anchoring options. Their strength, durability, and flexibility make them a reliable choice for creating stable scaffolding structures in various situations.

- Q:How do steel tube couplers affect the overall adaptability and versatility of scaffolding designs?

- The adaptability and versatility of scaffolding designs are significantly improved by steel tube couplers. These couplers play a crucial role in connecting steel tubes together, creating a stable and secure structure that can be easily adjusted and modified. One way in which steel tube couplers contribute to adaptability is by allowing tubes to be connected at different angles. By using different types of couplers, such as swivel couplers and right-angle couplers, scaffolding structures can be constructed to fit into irregular or confined spaces. This flexibility enables scaffolding to be adapted to meet the requirements of various construction and maintenance tasks. Furthermore, steel tube couplers provide versatility by enabling quick and easy assembly and disassembly of scaffolding systems. These couplers are designed to be securely tightened, ensuring the stability of the structure while also allowing for efficient adjustments or modifications. This versatility is particularly beneficial in projects with changing requirements or tight timelines, as scaffolding can be easily reconfigured or extended without significant time or effort. Another important aspect of steel tube couplers is their compatibility with different scaffolding components. These couplers can be used to connect steel tubes of varying sizes and lengths, as well as other scaffolding elements such as boards, platforms, and braces. This compatibility enables the construction of scaffolding systems that can support different loads and heights, meeting the specific needs of each project. In conclusion, steel tube couplers greatly enhance the adaptability and versatility of scaffolding designs. Their ability to connect tubes at different angles, facilitate quick assembly and disassembly, and compatibility with various scaffolding components make them essential in creating versatile and adaptable scaffolding structures.

- Q:What are the advantages of using steel tube couplers in scaffolding?

- There are several advantages of using steel tube couplers in scaffolding: 1. Strength and Durability: Steel tube couplers are made from high-grade steel, which provides exceptional strength and durability. They can withstand heavy loads and adverse weather conditions, making them ideal for construction projects that require sturdy scaffolding. 2. Versatility: Steel tube couplers can be used with a wide range of scaffold tubes, allowing for flexible configurations and easy assembly. This versatility makes them suitable for various construction applications, such as building maintenance, renovations, and infrastructure projects. 3. Safety: Steel tube couplers provide a secure and reliable connection between scaffold tubes, ensuring the stability and safety of the scaffolding structure. They are designed to prevent slippage or disconnection, reducing the risk of accidents and injuries. 4. Cost-effectiveness: Steel tube couplers are a cost-effective solution for scaffolding needs. They are relatively inexpensive compared to other scaffolding systems, and their durability ensures a longer lifespan, reducing the need for frequent replacements or repairs. 5. Easy Installation and Dismantling: Steel tube couplers are easy to install and dismantle, saving time and effort during construction projects. They do not require specialized tools or skills, making them accessible to a wide range of workers. 6. Compatibility: Steel tube couplers are compatible with various scaffolding accessories, such as platforms, boards, and guardrails. This compatibility allows for the customization and adaptation of scaffolding systems to meet specific project requirements. 7. Reduced Weight: Compared to traditional scaffolding systems, steel tube couplers are lightweight, which makes them easier to transport and handle. This advantage is particularly beneficial for projects that require frequent mobility or access to confined spaces. In summary, the advantages of using steel tube couplers in scaffolding include their strength, durability, versatility, safety, cost-effectiveness, ease of installation, compatibility with accessories, and reduced weight. These benefits make steel tube couplers an excellent choice for construction projects that require reliable and efficient scaffolding solutions.

- Q:Are there any specific guidelines for spacing steel tube couplers along a scaffolding structure?

- Yes, there are specific guidelines for spacing steel tube couplers along a scaffolding structure. These guidelines are defined by industry standards and regulations to ensure the safety and stability of the scaffolding. The spacing of steel tube couplers depends on various factors, including the type of scaffolding, the height of the structure, the load it will bear, and the specific requirements of the job site. Generally, the spacing between steel tube couplers should not exceed certain limits to prevent excessive deflection, instability, or failure of the scaffolding. The National Access and Scaffolding Confederation (NASC) in the UK provides comprehensive guidelines for scaffolding erection, including recommendations for the spacing of steel tube couplers. According to their guidelines, the maximum spacing between couplers on a single run of a scaffold tube should not exceed 2.5 meters. This is to maintain the structural integrity of the scaffold and prevent any potential hazards. Additionally, it is important to consider the requirements for bracing and tying of the scaffold structure. These guidelines suggest that couplers should be positioned at each end of a scaffold tube and at intervals not exceeding 2.5 meters along the length. This helps to ensure stability and prevent any movement or deformation of the structure. It is crucial to consult the specific regulations and standards applicable to your region or country, as they may vary. Local construction authorities or scaffolding organizations can provide detailed guidelines specific to your location. Overall, the spacing of steel tube couplers along a scaffolding structure is subject to specific guidelines to ensure the safety and stability of the scaffold. Adhering to these guidelines is essential to prevent accidents, maintain structural integrity, and comply with industry standards and regulations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Trustable Cuplock Scaffolding System with Best Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords