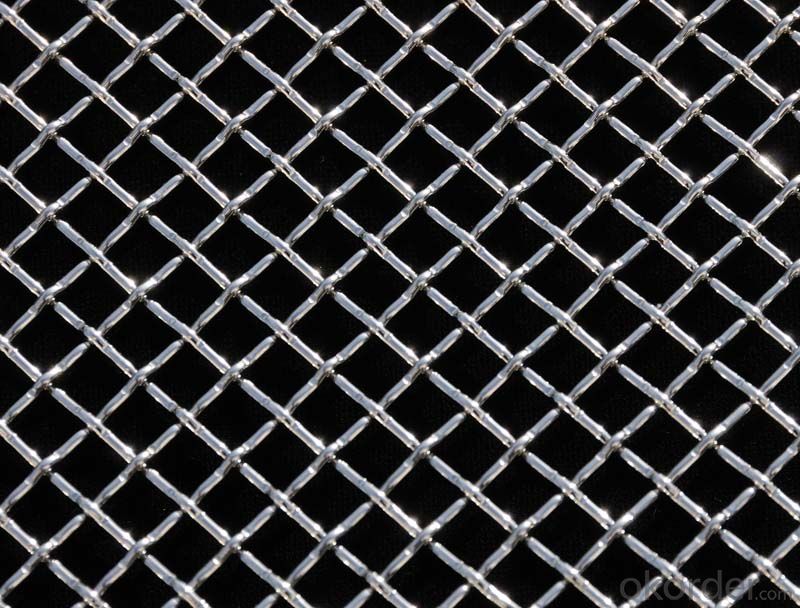

Crimped wire screen for Mine

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GeneralInformation

GeneralInformation

Type: blank/uncoated, galvanized*, stainless steel, aluminum,copper, brass, plastic-coated

• Width of the grid: 400 – 2.200 mm

• Length of the grid: 300 – 7.000mm, or in roll form up to 50

• Dimensional tolerances in lengthand width: -0 mm /+1 mesh width (customary)

• On request fixed measures withtolerances of +/-2 mm in length and width

Galvanized double intermediate crimp screens aremanufactured from previously galvanized wire. The zinc coating is ca. 7 µm.Galvanized double crimp screens therefore are only limitedly suitable foroutdoor use.

Product Range

Weight of double intermediate crimp screens – in kg/m² | ||||||||||

Mesh width [mm] | Wire diameter [mm] | Crimps* | ||||||||

1,6 | 1,8 | 2,0 | 2,5 | 3,0 | 3,4 | 4,0 | 5,0 | 5,8 | ||

8 x 8 | 3,5 |

|

|

|

|

|

|

|

| 3 |

10 x 10 | 3,0 | 4,2 | 4,5 |

|

|

|

|

|

| 3 |

12 x 12 |

|

| 3,8 |

|

|

|

|

|

| 3 |

15 x 15 |

|

| 3,1 | 4,7 | 6,7 |

|

|

|

| 3 |

20 x 20 |

|

| 2,4 | 3,7 |

|

|

|

|

| 5 |

20 x 20 |

|

|

|

| 5,0 | 6,8 | 9,5 |

|

| 3 |

25 x 25 |

|

|

| 3,1 | 4,3 |

|

|

|

| 5 |

25 x 25 |

|

|

|

|

| 5,5 | 7,7 |

|

| 3 |

30 x 30 |

|

|

| 2,7 |

|

|

|

|

| 7 |

30 x 30 |

|

|

|

| 3,8 | 4,6 |

|

|

| 5 |

30 x 30 |

|

|

|

|

|

| 6,0 | 10,7 |

| 3 |

35 x 35 |

|

|

|

| 2,9 | 4,1 | 5,2 |

|

| 5 |

40 x 40 |

|

|

| 2,4 |

|

|

|

|

| 9 |

40 x 40 |

|

|

|

| 2,8 |

|

|

|

| 7 |

40 x 40 |

|

|

|

|

| 3,5 | 4,7 |

|

| 5 |

40 x 40 |

|

|

|

|

|

|

| 7,3 | 10,2 | 3 |

50 x 50 |

|

|

|

| 2,3 |

|

|

|

| 9 |

50 x 50 |

|

|

|

|

| 2,9 | 3,8 |

|

| 7 |

50 x 50 |

|

|

|

|

|

|

| 5,8 | 8,1 | 5 |

60 x 60 |

|

|

|

|

|

| 3,3 |

|

| 7 |

60 x 60 |

|

|

|

|

|

|

| 5,3 | 6,9 | 5 |

75 x 75 |

|

|

|

|

|

|

| 4,4 | 5,9 | 7 |

100 x 100 |

|

|

|

|

|

|

| 3,5 | 4,5 | 9 |

Application Areas

Our doubleintermediate crimp screens are used in the following fields as:

Safety grids (e.g. car industry,mechanical engineering, building industry)

Filling elements for gates andfences in buildings and gardens

Booth construction

Plant breeding

Pigeon barriers

Noise protection

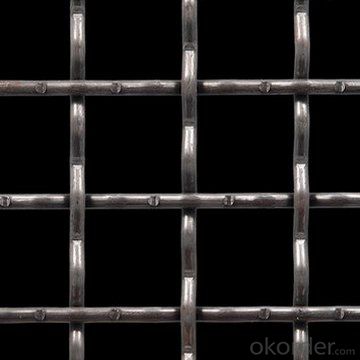

Lock crimp/Lock-Crimp Weave/Scalping Weave

Slotted screens (against flow)

Flat top screens with aone-sided plane surface have their chain and weft wires in plane position atthe intersection points due to the single-sided crimp of the wire. This methodgenerates a grid with a plane, unbroken bottom side.

General Information

Type:blank/uncoated, galvanized*,stainless steel, aluminium, copper, brass.

• Width ofthe grid: up to 2.200 mm

• Length ofthe grid: up to 5.000 mm or in roll form up to 50 m

•Dimensional tolerances in length and width: -0 mm /+1 mesh width (customary)

• Onrequest fixed measures with tolerances of +/-2 mm in length and width

The nominal size of the flat top screen always specifiesthe mesh width (=inner width).

Application Areas

Weight of flat top screens with a one-sided plane surface – in kg/m² | |||||

Mesh width [mm] | Wire diameter [mm] | ||||

2,0 | 2,5 | 3,0 | 4,0 | 5,0 | |

8 x 8 | 5,2 |

|

|

|

|

10 x 10 | 4,3 |

|

|

|

|

12 x 12 | 3,7 |

| 7,7 |

| 18,9 |

13 x 13 |

| 5,2 |

|

|

|

15 x 15 | 3,0 | 4,7 |

|

|

|

16 x 16 |

|

| 6,1 | 11,0 |

|

20 x 20 | 2,3 | 3,5 | 5,0 |

|

|

25 x 25 |

|

| 4,1 | 7,3 |

|

30 x 30 |

| 2,7 | 3,5 | 6,2 |

|

40 x 40 |

|

| 2,7 | 4,5 | 7,5 |

50 x 50 |

|

| 2,4 | 3,6 | 5,8 |

60 x 60 |

|

|

|

| 4,9 |

75 x 75 |

|

|

|

| 4,0 |

Flat topscreens with a one-sided plane surface are used in all fields where constantmesh width and the advantage of a one-sided plane surface are required, e.g.shelves, cage bottoms, support grids for filter fabric, stackable bin walls,security and cover grids. Flat top screens are becoming more and more importantas creative element in the architectural sector (e.g. as cladding for walls andceilings.)

Hook Strips for Screen Sections | ||

|

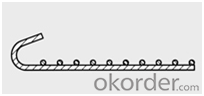

| Standard Hook Strip, Type 21, for side tensioning |

|

|

|

| Standrad Hook Strip, Type 21, for end tensioning | |

|

|

|

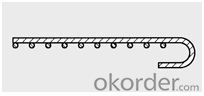

| Double Fold Hook Strip, Type 30, for side tensioning | |

|

|

|

| Double Fold Hook Strip, Type 30, for end tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for side tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for end tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for side tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for end tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

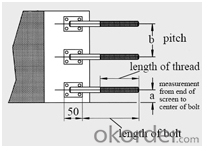

Tensioning Bolts | ||

| Flat Tensioning Bar with tensioning bolts. Please indicate measurements a + b and length of bolt. | |

- Q:How does steel wire mesh perform in high-pressure applications?

- Due to its inherent strength and durability, steel wire mesh proves itself as a reliable performer in high-pressure applications. Its tightly woven structure enables it to withstand and evenly distribute pressure, thus rendering it highly resistant to deformation or failure even in the face of extreme pressures. Moreover, steel wire mesh exhibits the ability to retain its structural integrity even when subjected to harsh environmental conditions or fluctuations in temperature. Consequently, it emerges as an optimal selection for high-pressure applications like filtration systems, hydraulic systems, and industrial processes that demand dependable and consistent performance under intense pressure.

- Q:What are the different surface textures available for steel wire mesh?

- Steel wire mesh offers a variety of surface textures, each with its own unique characteristics and benefits. Some of the most commonly used textures include: 1. Plain: This is a smooth and flat texture that is suitable when no specific texture or surface roughness is necessary. 2. Twilled: Twilled texture consists of diagonal lines formed by the weaving pattern of the wires. It provides a slightly rougher texture than plain, which can improve grip and prevent slippage in certain applications. 3. Crimped: Crimped texture is achieved by bending the wires during the weaving process. This increases the strength and stability of the mesh, making it ideal for heavy-duty applications or when extra rigidity is needed. 4. Woven: Woven texture refers to the pattern created by the interweaving of wires in a specific manner. It can vary depending on the weaving pattern used, such as plain weave, twill weave, or Dutch weave. Each pattern offers distinct characteristics in terms of strength, filtration capabilities, or visual aesthetics. 5. Expanded: Expanded texture is achieved by cutting and stretching metal sheets, resulting in a mesh with diamond-shaped openings. This texture provides a lightweight and rigid structure, making it suitable for applications requiring ventilation, filtration, or decorative purposes. 6. Welded: Welded texture is formed by welding individual wires at their intersection points. It creates a strong and durable mesh, commonly used in construction, fencing, or industrial applications where high strength and security are crucial. Ultimately, the choice of surface texture for steel wire mesh depends on the specific requirements of the application, including strength, rigidity, grip, filtration, or visual appearance.

- Q:How does steel wire mesh perform in water resistance?

- Steel wire mesh exhibits excellent performance when it comes to its ability to resist water. Its composition and construction render it impervious to corrosion and rust, thereby making it suitable for a wide range of applications in environments that are wet or submerged. The interlocked nature of the wire mesh ensures a robust and durable barrier that can endure the pressure and force exerted by water. Furthermore, the mesh structure facilitates efficient drainage, thereby reducing the accumulation of water and preventing potential damage that may arise from prolonged exposure to moisture. All in all, steel wire mesh is a dependable option for achieving water resistance, making it an ideal choice for applications including water filtration, the marine industry, construction, and other water-related purposes.

- Q:What are the different wire shapes available in steel wire mesh?

- The different wire shapes available in steel wire mesh include plain weave, twill weave, Dutch weave, and reverse Dutch weave.

- Q:Can steel wire mesh be used for safety barriers and fencing?

- Yes, steel wire mesh can definitely be used for safety barriers and fencing. Steel wire mesh is a versatile material that is commonly used in various applications due to its durability and strength. It is often employed in safety barriers and fencing as it provides a secure and reliable barrier to prevent unauthorized access or to ensure the safety of individuals in restricted areas. Steel wire mesh offers several advantages for safety barriers and fencing. Firstly, it is resistant to corrosion, making it suitable for outdoor use where it may be exposed to harsh weather conditions. Additionally, steel wire mesh is difficult to cut or penetrate, making it an effective deterrent against intruders. It also provides clear visibility, allowing for better monitoring and surveillance of the protected area. Furthermore, steel wire mesh can be easily customized to suit specific requirements. It can be constructed in various sizes, mesh patterns, and wire gauges, allowing for flexibility in design and application. This adaptability makes it suitable for a wide range of safety barrier and fencing needs, including securing construction sites, enclosing swimming pools, protecting machinery, and restricting access to restricted areas. Overall, steel wire mesh is a reliable and durable material that can be effectively used for safety barriers and fencing. Its strength, resistance to corrosion, and customization options make it a popular choice for ensuring security and safety in various settings.

- Q:What are the different mesh counts available for steel wire mesh?

- Steel wire mesh comes in a range of mesh counts, offering options from very fine to more open weaves. The mesh count indicates the number of openings or holes per linear inch in the mesh screen. For steel wire mesh, the most common mesh counts typically fall between 2 and 400. Coarse mesh counts, below 10, have larger openings and thicker wires, making them suitable for heavy-duty applications like mining screens or fencing. On the other hand, fine mesh counts, above 200, have smaller openings and thinner wires, making them ideal for precise filtration or separation in industries such as pharmaceuticals, food processing, and laboratory testing. Medium mesh counts, ranging from 12 to 100, strike a balance between strength and openness. They are commonly used in applications like filtration, separation, and reinforcement. These mesh counts provide durability while still allowing for adequate airflow or visibility. It is worth noting that the availability of specific mesh counts for steel wire mesh may vary depending on the manufacturer or supplier. Custom mesh counts can also be created to meet specific project requirements.

- Q:Is steel wire mesh resistant to chemicals used in water treatment?

- Generally, steel wire mesh is resistant to the chemicals commonly used in water treatment. It is typically made from stainless steel, which offers excellent chemical resistance. It can resist corrosion and withstand exposure to various chemicals, including chlorine, fluorine, and different acids used in water treatment. Due to this, steel wire mesh is a suitable choice for filtration, separation, and reinforcement in water treatment plants. However, it is important to note that the resistance of the wire mesh to specific chemicals can be influenced by the type and grade of stainless steel used. Therefore, it is advisable to consult the manufacturer or supplier to ensure compatibility with the specific chemicals used in the water treatment process.

- Q:Can steel wire mesh be used for mesh baskets?

- Yes, steel wire mesh can be used for mesh baskets. Steel wire mesh is commonly used for a variety of applications including mesh baskets. It is strong, durable, and resistant to corrosion, making it an ideal material for creating baskets that can withstand heavy loads and harsh conditions. The open design of the mesh allows for good airflow and visibility, making it suitable for storing and organizing items. Additionally, steel wire mesh can be easily customized to different sizes and shapes, allowing for flexibility in designing mesh baskets for specific needs.

- Q:How is steel wire mesh used in reinforcement of residential buildings?

- Steel wire mesh is commonly used in the reinforcement of residential buildings to enhance the structural integrity and durability of concrete structures. It is mainly used in areas where concrete is prone to cracking or where additional strength is required. One of the primary applications of steel wire mesh in residential buildings is in the construction of concrete slabs. The steel mesh is placed in the middle of the slab, creating a reinforcement layer that helps distribute the load evenly and prevent cracking. This is particularly important in areas with heavy foot traffic or where heavy loads such as furniture or appliances will be placed. Steel wire mesh is also used in the reinforcement of concrete walls. It is typically placed in the middle of the wall, parallel to the surface, to provide additional strength and prevent cracking. This is especially crucial in areas prone to seismic activity or where the soil conditions may cause the walls to shift or settle. In addition to slabs and walls, steel wire mesh is also used in the reinforcement of residential building foundations. By placing the mesh below the concrete footing, it helps distribute the load more evenly and prevents the foundation from cracking or settling. This is particularly important in areas with unstable soil or where the water table is high. Overall, steel wire mesh plays a crucial role in the reinforcement of residential buildings by providing additional strength and preventing cracking. It helps improve the longevity and stability of the building, ensuring that it can withstand various external forces such as heavy loads, seismic activity, and soil movements.

- Q:Hot galvanized steel wire mesh and galvanized steel mesh how to identify?

- then the surface color is relatively bright silver, the surface is smooth without a small zinc piece of solder and hot galvanized, then the color is darker, The surface is not smooth small zinc fast but are essentially silver white

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Crimped wire screen for Mine

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products