New Green PVC Coated Wire Mesh Fence with Multi-Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New Green PVC Coated Wire Mesh Fence with Multi-Purpose

1. Structure of PVC Coated Wire Mesh Fence Description:

Hexagonal wire mesh is also called chicken wire, poultry netting ,rabbit netting. It is common used to fence chicken, poultry, rabbit and other animals.

The hexagonal wire mesh is made of black iron wire, galvanized iron wire, brass wire or stainless steel wire with hexagonal gaps, available in3/8 inch to 4inch ( 10mm to 100mm),wire gauge from BWG14 to BWG27 (2.1mm to 0.4mm).

Hexagonal wire mesh is extensively used in industrial and agricultural construction, building works, and all such made for the purpose of reinforcing and fencing as protective cage, guards for window and machinery safety isolation, floor screen reinforcement and poultry cage, fishing, garden and children's play-ground.

2. Main Features of PVC Coated Wire Mesh Fence :

• Firm structure,

• Flat surface

• Beautiful shape

• Oxidation –resistant

• Nice vision

• Good anti-corrosion

• Anti-oxidation

3. PVC Coated Wire Mesh Fence Images

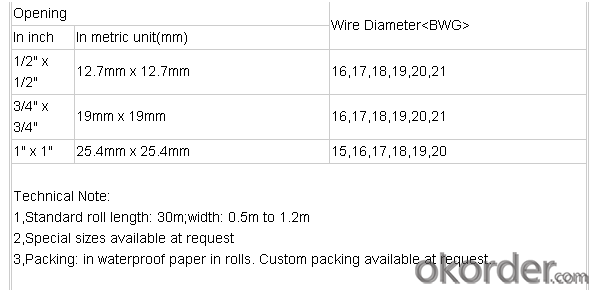

4. PVC Coated wire mesh Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your PVC Coated wire mesh?

Our company is the professional manufacture of PVC Coated wire mesh and any other wire mesh. We have more than 15years experience in producing welded wire mesh. Based on our experience, with our reasonable price, high quality and considerate service, our products enjoy high reputation in our market. Our main products like PVC Coated wire mesh, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia,South Asia, North America, and many other countries and regions.

② The reason why you choose us

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③ How long can we receive the product after purchase?

In the purchase of PVC Coated wire mesh within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q:Can steel wire mesh be used for water filtration?

- Yes, steel wire mesh can be used for water filtration. It has a fine mesh structure that can effectively filter out larger particles and impurities from water, making it suitable for various filtration applications.

- Q:What are the maintenance requirements for steel wire mesh?

- Steel wire mesh requires minimal maintenance, but it is still crucial to regularly inspect and clean it to ensure it lasts long and functions properly. Here are some essential maintenance guidelines for steel wire mesh: 1. Regularly clean the mesh to remove any accumulated dirt, debris, or contaminants. Use a brush or cloth to wipe away dirt, and for stubborn stains, utilize a mild detergent or non-abrasive cleaner. 2. Prevent rust formation by keeping the mesh dry and avoiding contact with corrosive substances or moisture. Applying a protective coating like paint or a rust-resistant spray can also help prevent rust. 3. Inspect the mesh regularly for damage, such as tears, holes, or loose connections, to maintain its structural integrity. Promptly repair any damages to prevent further deterioration and potential safety hazards. 4. Lubricate moving parts, such as hinges or joints, if present in the steel wire mesh. Use a lubricant specifically designed for metal surfaces to reduce friction and prevent wear and tear. 5. Protect the mesh from extreme weather conditions like heavy rain, snow, or prolonged exposure to direct sunlight. Install a cover or shelter to shield the mesh from these elements. By adhering to these maintenance requirements, steel wire mesh can remain in excellent condition and continue to effectively and safely serve its intended purpose.

- Q:Can steel wire mesh be used in construction?

- Certainly, construction can make use of steel wire mesh. This adaptable material presents numerous advantages for diverse construction purposes. In reinforced concrete structures, steel wire mesh is frequently employed to bolster their robustness and endurance. Similarly, in masonry work, it offers assistance and stability to walls and structures. Additionally, steel wire mesh serves as fencing and safety barriers at construction sites. Its exceptional tensile strength and resistance to corrosion establish it as a dependable option for construction endeavors.

- Q:Is steel wire mesh resistant to staining?

- Generally, steel wire mesh is resistant to staining. Typically, the steel wire used in the mesh is coated or treated with a protective layer to prevent corrosion and enhance its stain resistance. This protective layer can take the form of galvanization, PVC coating, or epoxy coating, among others. These coatings create a barrier between the steel wire and external elements, such as moisture, chemicals, and environmental factors that could cause staining. However, it is important to note that the level of stain resistance may vary depending on the specific type of steel wire mesh and the type of staining agent. In certain cases, exposure to strong chemicals or harsh environmental conditions may still result in minor discoloration or staining on the mesh. Regular cleaning and maintenance can help minimize potential staining and keep the steel wire mesh in optimal condition.

- Q:Can steel wire mesh be used for creating mesh screens?

- Yes, steel wire mesh can be effectively used for creating mesh screens. Steel wire mesh is known for its high strength, durability, and resistance to corrosion, making it an ideal material for constructing mesh screens. The tightly woven pattern of the wire mesh allows for the passage of air and light while effectively preventing the entry of insects, debris, or other unwanted particles. Additionally, steel wire mesh can be easily cut, shaped, and customized to fit various screen sizes and shapes, making it highly versatile for different applications. Whether for windows, doors, fencing, or industrial applications, steel wire mesh is a reliable choice for creating mesh screens due to its sturdiness and long-lasting performance.

- Q:Can steel wire mesh be used for fencing?

- Fencing can be done using steel wire mesh, which is known for its versatility and durability. This material is commonly used for various fencing purposes due to its strength, resistance to corrosion and weather conditions, and its ability to provide a high level of security. The use of steel wire mesh fencing is prevalent in industrial, commercial, and residential settings. It serves multiple purposes such as securing properties, creating boundaries, enclosing areas, and protecting assets. The design of the mesh allows for visibility while still acting as a barrier, making it suitable for areas where visibility is crucial. There are different sizes and gauges available for steel wire mesh fencing, enabling customization based on specific requirements. Its installation and maintenance are easy, and it can be adapted to various types and shapes of terrain. Moreover, steel wire mesh can be combined with other materials like posts, gates, and barbed wire to enhance the fence's security and effectiveness. It can also be coated with protective finishes to increase its durability and lifespan. In conclusion, steel wire mesh is a reliable and cost-effective choice for fencing. It offers strength, security, and versatility, making it an excellent option for various fencing needs.

- Q:Can steel wire mesh be used for landscaping purposes?

- Yes, steel wire mesh can be used for landscaping purposes. It is commonly used as a fencing material for gardens and can help to define boundaries, protect plants from animals, and add a decorative element to the landscape. Additionally, steel wire mesh can be utilized to create trellises and support structures for climbing plants, such as vines and creepers. It can also serve as a barrier for retaining walls, preventing soil erosion and providing stability. Steel wire mesh is durable and long-lasting, making it a practical choice for various landscaping applications.

- Q:Can steel wire mesh be used for creating partitions in warehouses?

- Yes, steel wire mesh can be used for creating partitions in warehouses. Steel wire mesh is a versatile and durable material that can effectively divide large open spaces into separate areas. It provides a strong and secure barrier, ensuring the separation of different sections within a warehouse. Steel wire mesh partitions are commonly used to create storage spaces, secure sensitive areas, or separate specific work zones. They are easy to install, cost-effective, and can be customized to fit any warehouse layout. Additionally, steel wire mesh allows for visibility and airflow, providing a safe and well-ventilated environment for warehouse personnel. Overall, using steel wire mesh for creating partitions in warehouses is a practical solution that offers flexibility, security, and efficient space utilization.

- Q:What are the benefits of using steel wire mesh in the telecommunications recycling industry?

- There are several benefits of using steel wire mesh in the telecommunications recycling industry. First and foremost, steel wire mesh is incredibly strong and durable. This means that it can withstand the heavy loads and constant wear and tear that are often associated with the recycling industry. This strength and durability ensure that the wire mesh can effectively contain and protect the valuable telecommunications equipment during the recycling process, minimizing the risk of damage or loss. Additionally, steel wire mesh is highly resistant to corrosion. This is particularly important in the telecommunications recycling industry, as many of the equipment and components being handled may contain corrosive substances or have been exposed to harsh environmental conditions. By using steel wire mesh, the risk of corrosion is significantly reduced, ensuring the longevity of the equipment and maintaining its value during the recycling process. Furthermore, steel wire mesh is highly versatile and can be customized to fit specific requirements. In the telecommunications recycling industry, where equipment sizes and shapes can vary greatly, having a flexible and adjustable containment solution is crucial. Steel wire mesh can be easily cut and shaped to fit any equipment or storage area, providing a secure and tailored solution for handling and storing telecommunications devices during recycling. Another benefit of steel wire mesh is its transparency. Unlike solid barriers, wire mesh allows for clear visibility of the equipment being stored or transported. This visibility is important in the telecommunications recycling industry, as it allows for easy visual inspection, identification, and organization of the equipment, enhancing efficiency and reducing the chances of errors or mix-ups. Lastly, steel wire mesh is a sustainable choice. Steel is a highly recyclable material, and using wire mesh made from recycled steel further contributes to the environmental sustainability of the telecommunications recycling industry. By opting for steel wire mesh, companies can align their operations with green initiatives and reduce their carbon footprint. In summary, the benefits of using steel wire mesh in the telecommunications recycling industry include its strength and durability, corrosion resistance, versatility, transparency, and sustainability. These advantages make steel wire mesh an ideal choice for securely containing and protecting valuable equipment throughout the recycling process, ensuring efficiency, longevity, and environmental responsibility.

- Q:How is steel wire mesh used in reinforcement of slabs?

- Steel wire mesh is commonly used in the reinforcement of slabs to enhance their strength and durability. It is placed within the concrete mixture to provide additional support and prevent cracking. The mesh helps distribute the load evenly across the slab, reducing the risk of structural failure and improving its overall performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New Green PVC Coated Wire Mesh Fence with Multi-Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords