Bearing Steel Rod 52100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Steel Grade: | Standard: | Dimensions: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Technique: | Application: | Alloy Or Not: | |||

| Special Use: | Type: | Grade: | |||

| Surface treatment: | Delivery condition: | Main products: | |||

| Trade term: |

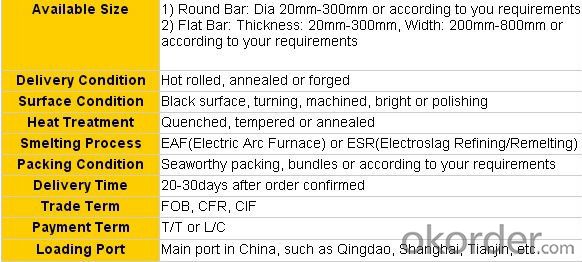

Packaging & Delivery

| Packaging Detail: | GCr15 bearing steel: Seaworthy package or according to buyers' requirement |

| Delivery Detail: | 30days |

Specifications

Bearing Steel Rod 52100

1)Competitive price

2)High chromium bearing steel

3)ISO 9001:2008 and SGS

Bearing Steel Rod 52100

Steel Material: ASTM 52100,JIS SUJ2,BS100Cr6, GB GCr15 high-carbon chromium bearing steel

Similar or Equivalent Grades

GB | AISI | ISO | JIS |

GCr15 | 52100 | 100Cr6 | SUJ2 |

Chemical composition

Mechanical Property

Delivery State | |

Brinell Hardness HBS | Impression Diameter /mm |

179-207 | 4.2-4.5 |

Characteristics

1) Good hardability and high toughness

2) Long fatigue life

3) Medium cold processing plasticity

4) Certain machinability

5) Poor weldability

Application

1) Steel ball, roller and collar of large machinery bearing

2) High-hardness and high contact fatigue strength machinery parts with heavy load, such as axis of rotation, blade, stator pump, profiling, sleeve, mandril, etc.

Description Details

- Q:How is weathering steel used in outdoor structures?

- Weathering steel is commonly used in outdoor structures due to its unique ability to form a protective rust-like coating, which not only enhances its aesthetic appeal but also acts as a barrier against further corrosion. This steel is often utilized in bridges, sculptures, buildings, and other architectural elements, providing durability, strength, and a distinct rust-colored appearance that blends harmoniously with the natural surroundings.

- Q:What is the chemical composition of special steel?

- Special steel is a broad term that encompasses a variety of steel alloys with specific properties and characteristics. The chemical composition of special steel can vary depending on the specific grade or type of steel being referred to. However, in general, special steel often contains higher amounts of alloying elements compared to regular carbon steel. These alloying elements can include elements such as chromium, nickel, molybdenum, vanadium, tungsten, and others. The specific combination and proportion of these alloying elements determine the unique properties of special steel, such as increased strength, enhanced corrosion resistance, improved heat resistance, or better wear resistance. For example, some common types of special steel include stainless steel, which typically contains high amounts of chromium and nickel, providing excellent corrosion resistance; tool steel, which has high carbon content and often contains other elements like vanadium or tungsten, making it suitable for cutting, drilling, or shaping tools; and high-speed steel, which contains elements like molybdenum, cobalt, or tungsten, giving it exceptional hardness and heat resistance for use in cutting tools or drills. In summary, the chemical composition of special steel varies depending on the specific type or grade, but it generally includes higher amounts of alloying elements to achieve desired properties such as strength, corrosion resistance, heat resistance, or wear resistance.

- Q:What are the different special steel products available in the market?

- There are a wide variety of special steel products available in the market, each designed to meet specific industrial needs. Some of the common special steel products include: 1. Stainless Steel: This is a corrosion-resistant steel alloy that contains a minimum of 10.5% chromium. It is widely used in applications that require high resistance to corrosion, such as kitchen utensils, medical instruments, and chemical processing equipment. 2. Tool Steel: Tool steel is a type of carbon and alloy steel that is specifically designed to be used in the manufacturing of tools. It is known for its high hardness, resistance to abrasion, and ability to retain sharp edges. Tool steel is commonly used in the production of cutting tools, dies, and molds. 3. Alloy Steel: Alloy steel is a steel that has been alloyed with other elements, such as manganese, silicon, nickel, or chromium, to enhance its mechanical properties. It offers improved strength, toughness, and wear resistance compared to carbon steel. Alloy steel is used in various applications, including automotive components, construction equipment, and machinery parts. 4. High-Speed Steel: High-speed steel is a type of tool steel that is capable of cutting at high speeds without losing its hardness or ability to retain sharp edges. It is commonly used in the production of drills, milling cutters, and saw blades. 5. Spring Steel: Spring steel is a low-alloy, medium or high carbon steel that is known for its ability to retain its shape and elasticity even under high stress or repeated loadings. It is widely used in the manufacturing of springs, suspension systems, and shock absorbers. 6. Electrical Steel: Electrical steel, also known as silicon steel, is a specialized steel alloy that exhibits low electrical losses and high magnetic permeability. It is used in the production of electrical transformers, motors, and generators. 7. Heat-Resistant Steel: Heat-resistant steel is designed to withstand high temperatures without losing its mechanical properties. It is commonly used in applications such as furnaces, heat exchangers, and gas turbines. These are just a few examples of special steel products available in the market. The choice of steel product depends on the specific requirements of the application, including factors such as corrosion resistance, strength, hardness, and heat resistance.

- Q:How does special steel contribute to the thermal conductivity of products?

- Special steel contributes to the thermal conductivity of products by having a higher thermal conductivity compared to other materials. This means that when special steel is used in the production of products, it allows for efficient transfer of heat, resulting in better heat distribution and dissipation.

- Q:How is high-temperature stainless steel used in the production of gas turbines?

- High-temperature stainless steel is used in the production of gas turbines due to its exceptional heat resistance and corrosion resistance properties. It is utilized to make critical components such as turbine blades, rotors, and casings that are exposed to extreme temperatures and harsh environments. This stainless steel helps gas turbines operate efficiently and reliably by withstanding high temperatures without losing strength or degrading, ultimately enhancing the performance and lifespan of gas turbines.

- Q:How is tool steel used in the manufacturing of molds and dies?

- Tool steel is commonly used in the manufacturing of molds and dies due to its excellent hardness, toughness, and wear resistance properties. It is used to create molds and dies that can withstand high pressures and temperatures during the manufacturing process. Tool steel is ideal for shaping and forming materials, such as plastic or metal, as it provides the necessary strength and durability to produce accurate and precise components. Additionally, tool steel can be easily machined and heat-treated to enhance its performance, making it an essential material in the manufacturing industry.

- Q:How does special steel contribute to the aerospace landing gear industry?

- Special steel plays a vital role in the aerospace landing gear industry by providing the necessary strength, durability, and resistance to extreme conditions. It enables the landing gear to withstand heavy loads, high temperatures, and corrosive environments, ensuring the safe landing and takeoff of aircraft. Additionally, special steel's lightweight properties help reduce the overall weight of the landing gear, resulting in improved fuel efficiency and increased payload capacity.

- Q:How does special steel contribute to reducing product downtime?

- Special steel contributes to reducing product downtime by offering enhanced durability and resistance to wear, corrosion, and high temperatures. Its unique properties enable components made from special steel to withstand harsh operating conditions and maintain their integrity over extended periods. By using special steel in critical parts, manufacturers can minimize the frequency of component failures, repairs, and replacements, thereby reducing product downtime and increasing overall productivity.

- Q:What are the different methods of surface cleaning for special steel?

- There are several different methods of surface cleaning for special steel, including mechanical methods such as abrasive blasting or grinding, chemical methods like pickling or passivation, and electrochemical methods such as electrocleaning or electropolishing. Each method has its own advantages and is chosen based on the type of contamination or surface condition that needs to be addressed.

- Q:Can special steel be used in the medical device manufacturing industry?

- Yes, special steel can be used in the medical device manufacturing industry. Special steel alloys, such as stainless steel, are commonly used in the production of medical devices due to their excellent corrosion resistance, biocompatibility, and mechanical properties. These materials provide durability, sterilization compatibility, and are suitable for various medical applications, including implants, surgical instruments, and diagnostic equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bearing Steel Rod 52100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords