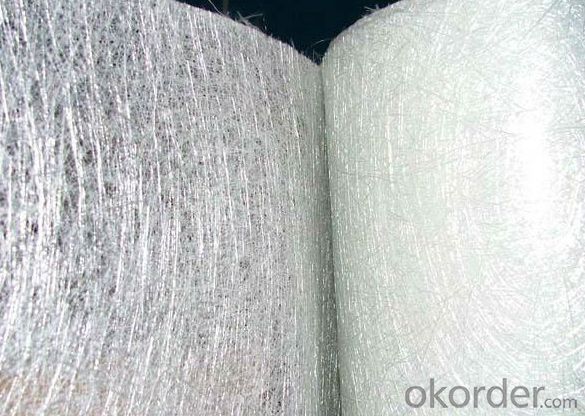

E-glass Chopped Strand Mat 2700mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 2700mm

2.Main Features

With Excellent compatibility with resin,heating resistance,Faster and well wet-out

Chopped strand mats are made of chopped strands of 50mm in length,which are randomly dispersed and bonded together by the polyester binder in powder or emulsion.

Chopped strand mats are mainly used in FRP fields,such as hand lay-up,filament winding and molding process. The typical products are panels,tanks,boats,automotive parts,cooling towers,pipes and so on.

3.Specifications

Bond type: Powder or Emulsion.

Density: 80g/m2-900g/m2.

Bond Content: 100g/m2 (10%-15%). 300g/m2.450g/m2.600g/m2 (4%-6%)

Roll Width: 2700mm.

Normal types :750mm.1040mm.1250mm.1270mm.1450mm.

4.FAQ

Q: Can you supply samples for us?

A: Yes we can send you sample with few quantity

- Q:Does fiberglass mat tissue absorb water?

- Yes, fiberglass mat tissue does absorb water.

- Q:Is fiberglass mat tissue suitable for sound absorption?

- Fiberglass mat tissue is indeed appropriate for sound absorption. Its exceptional acoustic properties make it a highly efficient material for decreasing noise levels and enhancing sound quality in different settings. The fibrous composition of the mat tissue offers a large surface area capable of absorbing sound waves and converting them into heat energy. This renders it an optimal choice for soundproofing walls, ceilings, and floors in buildings, as well as for automotive, industrial, and marine applications. Moreover, fiberglass mat tissue is lightweight, simple to install, and possesses excellent durability and fire resistance, further augmenting its aptness for sound absorption objectives.

- Q:Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. Fiberglass mat tissue is a versatile material that can be used with various types of resin systems, including polyester, epoxy, and vinyl ester resins. It has excellent wet-out properties, meaning that it can easily absorb and distribute the resin evenly throughout the mat. This compatibility allows for the creation of strong and durable composite structures in a wide range of applications such as automotive, marine, construction, and aerospace industries. However, it is important to consider the specific properties and characteristics of the resin system being used in order to ensure optimal performance and compatibility with the fiberglass mat tissue.

- Q:Does fiberglass mat tissue provide any sound insulation?

- Yes, fiberglass mat tissue does provide sound insulation. It is a common material used in various industries, including construction and automotive, to absorb and reduce sound transmission. The fibrous structure of the material helps to trap and absorb sound waves, preventing them from passing through walls or other surfaces. Fiberglass mat tissue is often used as an acoustic insulation material in walls, floors, and ceilings to create a more comfortable and noise-free environment.

- Q:Is fiberglass mat tissue suitable for electrical insulation applications?

- Yes, fiberglass mat tissue is suitable for electrical insulation applications. It possesses excellent dielectric properties, high tensile strength, and thermal resistance, making it an ideal material for insulating electrical components and preventing electrical current leakage.

- Q:Can fiberglass mat tissue be used for making boat hulls?

- Fiberglass mat tissue is indeed suitable for the construction of boat hulls. This lightweight and robust material is widely employed in the boat-building and repairing industry. By combining fiberglass strands with a binder, a flexible mat is formed, allowing for easy shaping and molding into various forms. Boat hulls necessitate a sturdy, water-resistant material with excellent structural integrity, all of which fiberglass mat tissue offers. Moreover, this material is relatively easy to manipulate and can be layered to enhance its strength according to requirements. Consequently, it is a favored option for constructing boat hulls.

- Q:Can fiberglass mat tissue be used for making lightweight furniture?

- No, fiberglass mat tissue is not typically used for making lightweight furniture. It is primarily used as a reinforcement material in applications such as insulation, automotive parts, and construction, but not for furniture production.

- Q:Can fiberglass mat tissue be used for making insulation panels?

- Yes, fiberglass mat tissue can be used for making insulation panels. It is a commonly used material due to its excellent thermal insulation properties and its ability to resist heat and cold. Additionally, fiberglass mat tissue is lightweight, durable, and can be easily molded into various shapes and sizes, making it suitable for insulation panel production.

- Q:Can fiberglass mat tissue be used for insulation boards?

- Yes, fiberglass mat tissue can be used for insulation boards. It is frequently utilized in insulation boards due to its excellent thermal and acoustic insulation properties. The fiberglass mat tissue helps to enhance the insulation capabilities of the boards, making them more energy-efficient and effective in reducing heat transfer and sound transmission.

- Q:Can fiberglass mat tissue be used for soundproofing?

- Indeed, soundproofing can be achieved with the utilization of fiberglass mat tissue. Renowned for its remarkable sound absorption capabilities, fiberglass proves to be an exceptional choice. Whether employed as a mat or tissue, it effectively diminishes noise transmission by absorbing and attenuating sound waves. The porous composition of fiberglass enables it to capture and disperse sound energy, rendering it a perfect material for soundproofing purposes. Furthermore, fiberglass possesses the advantages of being lightweight, flexible, and straightforward to install, thus making it an exceedingly convenient option for soundproofing endeavors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Chopped Strand Mat 2700mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords