AUTOMATIC AEROSOL HIGH PRESSURE LEAK TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

high pressure difference inspection

non-destructive inspecting

parameter control

digital display

quick to change can size

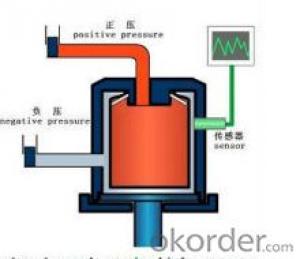

Ths machine adopts a hermetic device to insulate the interior and exterior of the empty can. Empty cans are transfered to the hermetic sleeve, then fill with 8-12bar compressed air into the empty cans, at the same time, pumping out 0.2-0.4 bar from the exterior of the empty cans, thus, there will have a value comes from the interior and exterior high pressure different; pressure sensor is set in a vacuum space, which measure the pressure in the beginning value and at the end value during the holding time,then making comparison two of them, the over value can will be rejected out as defective can.

Specialist for on line leak tester and on line vision inspection, high pressure leak tester for aerosol can, vacuum leak tester for food can, on line vision inspection for body and end.

Main Technical Datas

Model | EST-P15 | EST-P24 | EST-P36 |

Diameter | 45-65mm | 45-65mm | 45-65mm |

Height | 80-330mm | 80-320mm | 80-320mm |

Detectable leak | Up to 2cc/10bar/ min 2.5cc/8bar/min | Up to 2cc/10bar/min | Up to 2cc/10bar/min |

Capacity | 120cpm | 200cpm | 320cpm |

Working heads | 15 | 24 | 36 |

Compressed air | 8 to 10bar | 8 to 10bar | 8 to 10bar |

Air consumption | 3M3/min | 2.5M3/min | 3M3/min |

Power | 3kw | 5kw | 5kw |

- Q:Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

- Q:What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q:What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q:What is the working principle of the pillow packing machine?

- In fact, the special machine is often better than the packaging of the compatible machine. A packing machine should be packed in no more than 3-5 varieties. What's more, the products with the larger size and the difference in size should be packed separately as much as possible.

- Q:What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q:Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q:What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

- Q:The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q:Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q:What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AUTOMATIC AEROSOL HIGH PRESSURE LEAK TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords