Quick Assembly Slab Formwork System with Ring Lock Scaffolding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1. Brief introduction

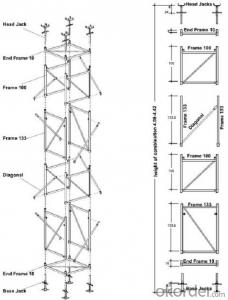

FA-TNOR system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, it is good choice for slab construction.

2. About the infill areas

Like RA-INST system, infill materials are necessary for small space or same special area. They are usually composed of timber beam, head-jack, scaffold support, and plywood as the below picture shown.

3. Competitive advantage

① Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover.

②Easy operation

The formwork is composed of plywood, timber beam, channel beam, connectors and ring-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

③Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

④Mature system with specific tools for removing.

We afford trolley for FA-TNOR system, trolley is especially for shifting table formwork from the slab, it guarantees easy operation and safe removing.

4. Applications

- Q:Can steel tube couplers be used in scaffolding projects with multiple levels or tiers?

- Indeed, scaffolding projects with multiple levels or tiers can employ steel tube couplers. These couplers are specifically engineered to connect and secure steel tubes, thereby establishing a robust and steadfast structure for scaffolding. They find frequent application in construction endeavors necessitating multiple levels or tiers of scaffolding. These couplers possess versatility, enabling the creation of diverse configurations and layouts, thereby permitting flexibility in scaffolding design. Furthermore, steel tube couplers exhibit durability and can endure substantial loads, thereby guaranteeing the safety and stability of the scaffolding structure.

- Q:How do steel tube couplers perform in areas with high levels of electromagnetic fields?

- Steel tube couplers perform well in areas with high levels of electromagnetic fields. The use of steel as a material for couplers provides excellent shielding properties against electromagnetic interference (EMI). Steel is a highly conductive material, which means it can effectively divert and absorb electromagnetic waves, preventing them from interfering with the performance of the couplers. In areas with high levels of electromagnetic fields, such as near power lines or electrical equipment, the steel tube couplers act as a barrier, preventing the electromagnetic waves from penetrating through and causing interference. This shielding effect helps maintain the integrity and reliability of the couplers, ensuring their optimal performance even in challenging electromagnetic environments. Moreover, steel tube couplers are commonly used in various industries, including telecommunications, power transmission, and construction, where high levels of electromagnetic fields are prevalent. They are specifically designed and manufactured to withstand these environmental conditions. Overall, steel tube couplers are a reliable choice for areas with high levels of electromagnetic fields due to their excellent shielding properties and ability to maintain optimal performance in challenging electromagnetic environments.

- Q:Are steel tube couplers compatible with different types of scaffolding stairs or access systems?

- Yes, steel tube couplers are typically compatible with different types of scaffolding stairs or access systems. Steel tube couplers are commonly used in scaffolding construction to connect tubes together, allowing for the creation of various scaffolding structures, including stairs and access systems. These couplers are designed to provide a secure and reliable connection between different scaffolding components, ensuring stability and safety. Whether it is a single or double coupler, swivel coupler, or sleeve coupler, they are generally designed to fit standard scaffolding tubes, which are commonly made of steel. However, it is important to ensure that the specific coupler being used is compatible with the type and size of the scaffolding stairs or access system being constructed. Different manufacturers may have variations in their coupler designs, so it is advisable to consult the product specifications or seek professional advice to ensure compatibility.

- Q:What are the common sizes and dimensions of steel tube couplers?

- The specific application and industry requirements determine the varying common sizes and dimensions of steel tube couplers. However, there are standard sizes commonly used. Steel tube couplers are available in different diameters and lengths to accommodate various tubing sizes. For instance, in the construction industry, steel tube couplers are frequently utilized for scaffolding and structural purposes. The outer diameter of the most commonly used sizes ranges from 48.3mm (1.9 inches) to 60.3mm (2.375 inches). The lengths of these couplers can vary from approximately 80mm (3 inches) to 100mm (4 inches) or even longer. In industrial applications like piping systems, the sizes of steel tube couplers can be much larger. These couplers can have outer diameters ranging from a few inches to several feet, corresponding to the size and weight requirements of the connected pipes. It is essential to note that the dimensions and sizes of steel tube couplers may also depend on the specific standards and regulations followed in different regions or industries. Therefore, it is always advisable to consult the relevant codes and specifications to ensure the correct selection of couplers for a specific application.

- Q:Can steel tube couplers be used in scaffolding projects requiring frequent height adjustments?

- Scaffolding projects that require frequent height adjustments can utilize steel tube couplers. These couplers are commonly used in the construction industry to connect and join scaffold tubes, providing a secure and stable connection. The design of steel tube couplers allows for easy adjustments, making them ideal for projects where height changes are necessary. This is especially useful when working on multi-level structures or when different tasks require modifications to the scaffolding height. Furthermore, steel tube couplers are highly durable and resistant to wear and tear, making them suitable for long-term use in scaffolding projects. They can withstand heavy loads and provide a reliable connection that ensures the stability and safety of the scaffolding structure. When using steel tube couplers in scaffolding projects, it is crucial to follow proper procedures and safety guidelines. Regular inspections of the couplers and scaffold tubes are necessary to ensure they are correctly connected and in good condition. Adhering to the maximum load capacity of the scaffolding and using the appropriate type and size of couplers for the specific project requirements is also essential. Overall, steel tube couplers offer versatility and reliability for scaffolding projects that require frequent height adjustments. They provide a strong and secure connection, allowing for efficient modifications in height while ensuring the safety and stability of the scaffolding structure.

- Q:What are the advantages of using steel tube couplers over other types of couplers in scaffolding?

- Using steel tube couplers in scaffolding offers several benefits. Firstly, they are renowned for their strength and durability, guaranteeing a secure connection between scaffolding tubes and the ability to endure heavy loads. This makes them the perfect choice for construction projects that necessitate a stable and dependable structure. Additionally, steel tube couplers are incredibly versatile and can be employed in various configurations. They effortlessly attach to scaffolding tubes of different sizes, granting flexibility in constructing scaffolding systems. This adaptability makes them suitable for a wide array of applications and ensures compatibility with existing scaffolding equipment. Another advantage of steel tube couplers is their user-friendly nature. They boast a straightforward design that facilitates swift and efficient installation. This saves both time and effort during the assembly and disassembly of scaffolding systems, ultimately enhancing productivity on the job site. Furthermore, steel tube couplers exhibit excellent resistance to corrosion. They are frequently galvanized or coated with protective materials to prevent rust and corrosion, guaranteeing their durability in harsh environments. This corrosion resistance renders them a reliable choice for outdoor projects, particularly in areas with high humidity or exposure to the elements. Lastly, steel tube couplers possess a remarkable load-bearing capacity. They can withstand substantial weight without compromising the stability of the scaffolding structure. Consequently, they are well-suited for heavy-duty construction projects that necessitate scaffolding capable of supporting heavy equipment or materials. To summarize, the advantages of utilizing steel tube couplers in scaffolding include their strength, versatility, ease of use, resistance to corrosion, and high load-bearing capacity. These qualities establish them as the preferred choice for construction professionals seeking a reliable and durable coupler option.

- Q:Can steel tube couplers be used in both interior and exterior scaffolding applications?

- Yes, steel tube couplers can be used in both interior and exterior scaffolding applications. They are versatile and strong enough to withstand various environmental conditions and provide a secure connection between scaffold tubes for both indoor and outdoor projects.

- Q:Are steel tube couplers adjustable to accommodate different scaffold configurations?

- Steel tube couplers possess the ability to be adjusted in order to accommodate various scaffold configurations. These couplers are specifically designed to securely connect steel tubes, forming a stable scaffold structure. They are available in different types, such as swivel couplers, sleeve couplers, and putlog couplers, each with its own adjustable characteristics. For instance, swivel couplers are equipped with a rotating mechanism that enables a 360-degree rotation. This allows for the connection of tubes at different angles, accommodating diverse scaffold configurations. On the other hand, sleeve couplers offer adjustable length options, allowing for flexibility in adjusting the distance between tubes. Moreover, steel tube couplers generally come with tightening bolts or nuts. These features facilitate easy adjustments and ensure a tight and secure connection between the tubes. As a result, scaffolds can be assembled and dismantled conveniently based on specific project requirements and various scaffold configurations. Overall, steel tube couplers are highly adaptable and adjustable. This makes them suitable for accommodating a wide range of scaffold configurations, ensuring the safety and stability of the structure.

- Q:Are steel tube couplers resistant to vibrations from machinery or equipment?

- Yes, steel tube couplers are resistant to vibrations from machinery or equipment due to their strong and rigid construction, which helps to minimize the transmission of vibrations and ensures stability and durability in various industrial applications.

- Q:Are steel tube couplers compatible with scaffolding safety nets and barriers?

- Yes, steel tube couplers are compatible with scaffolding safety nets and barriers. Steel tube couplers are designed to connect and secure scaffolding tubes together, providing a stable and secure structure. Safety nets and barriers are typically attached to the scaffolding structure to prevent falls and protect workers. Steel tube couplers can be used to securely attach these safety nets and barriers to the scaffolding, ensuring a safe working environment. It is important to ensure that the couplers are properly installed and that the scaffolding structure is designed to support the weight and load of the safety nets and barriers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Quick Assembly Slab Formwork System with Ring Lock Scaffolding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches