cold rolled coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Cold Rolled Steel Coil/Sheet:

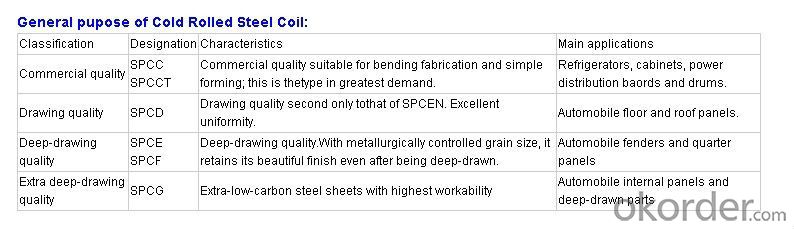

1)Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2)Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3)Thickness: 0.18mm - 3.0mm

4)Width: 600/1000/1250/1500 (mm) or per customer's request

5)Coil ID: 508mm/610mm or per customer's request

B:Package of Cold Rolled Steel Tape:

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or

wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

C: Applications for cold rolled Steel coil:

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel Coil: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

D:Process of Cold Rolled Steel Tape:

a: Pickling: To clean the dust and rust points on the surface.

b: Cold Rolling: Digital rolling control system produces minimum thickness tolerance, helps to prevent twist and improve straightness.

c: Slitting: Precise slitting machinery helps control the best width tolerance and avoid camber or cracker. Also we can make round or sharp edge with additional process and special machines.

d: Heat treatment: Advanced annealing, tempering and hardening techniques will help to produce proper mechanical property of the products to insure our client’s usage with minimum harm to natural environment.

E

F: Applications of Cold Rolled SteelCoil:

1) For the further producing of hot dip galvanized steel products

2) Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

Shipment time

within 30 workdays

Payment

T/T, L/C at sight

Market

North/South America, Europe, Asia, Africa, Mid East, ect.

Authentification

ISO9001:2000

- Q:What are the environmental and social impacts of mining, processing and using steel?

- It contains less than 0.25 % carbon. These steels are hot worked and produced for beam and structural application. Low carbon steels are not hardened appreciably by hardening process of heat treatment. A decrease in carbon content improves ductility mild steels are used for wires, rods, thin sheets, solid drawn tube, boiler plates, steel joints, channels and angles, structural sections, drop forgings. they are further classifies into dead mild, and mild steel dead mild steel It contains 0.05% to 0.15% carbon. It is used for making steel wires, sheets, rivets, screws, pipe, nail and chain. It has a tensile strength of 390 N/mm2 and a hardness of about 115 BHN. there are many company which produce their products from this raw material like tube, pipe, S31803 Duplex tube fitting, pipe fitting etc

- Q:What are the different types of steel coil coatings available?

- There are several different types of steel coil coatings available, including polyester, polyurethane, siliconized polyester, fluorocarbon, and plastisol coatings. Each type of coating offers specific properties and benefits, such as durability, corrosion resistance, weatherability, and aesthetics, making them suitable for various applications in industries such as construction, automotive, and appliances.

- Q:is red steel any good??????? not sure im really impressed but im not really into fighting games but it looks cool.... so whats your views guys???????anyone bored of smooth moves yet?anyone think the new sonic is bit cra ppy !!!!!!!!!!! darn them any new goooood games coming oput on the wii??

- Have you tried Zelda or Trauma Center? Those should give you a good ride for your money. If you have a few bucks lying around pick either of them up.

- Q:What are the different types of steel coil handling equipment?

- Some different types of steel coil handling equipment include coil lifters, coil tongs, coil grabs, coil hooks, coil transfer cars, and coil upenders. These equipment are designed to safely lift, transport, and rotate steel coils during various industrial processes.

- Q:What are the different types of steel coil edge conditioning methods?

- There are several different types of steel coil edge conditioning methods, including slitting, trimming, deburring, chamfering, and edge rolling.

- Q:I want to buy a machete made of 1055 carbon steel, and want to know if this steel is durable for repeated use, or even combat use.

- From okorder /

- Q:I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Your blade was overheated. Change it into diamond blade shall do.

- Q:Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appearance, protect them from corrosion, or improve their performance in various applications.

- Q:How are steel coils used in the manufacturing of industrial boilers?

- Steel coils are used in the manufacturing of industrial boilers as they provide structural support and ensure the durability and strength of the boiler. These coils are often used to construct the boiler's pressure vessel, which contains the water or steam under high pressure. Additionally, steel coils are used for various components such as tubes, pipes, and flanges, which are integral to the functioning of the boiler. Overall, steel coils play a crucial role in the construction and performance of industrial boilers.

- Q:What is the minimum diameter of a steel coil?

- The minimum diameter of a steel coil can vary depending on the specific requirements and manufacturing processes, but it is typically around 4 inches or 100 millimeters.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

cold rolled coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords