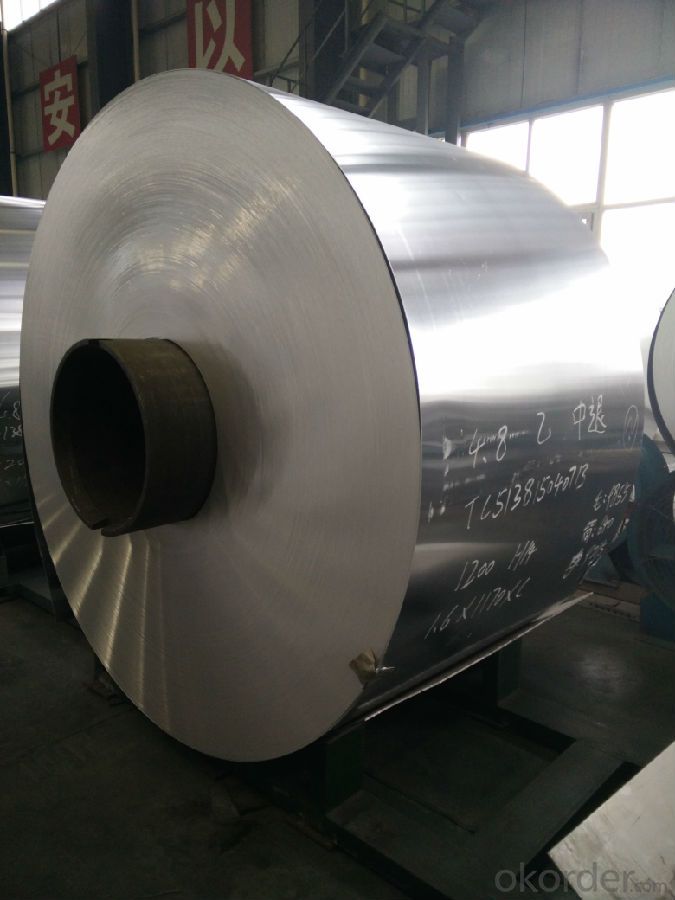

Roll of Aluminum 3003 H14 /1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Roll of Aluminum 3003 H14 /1100 H14

Roll of Aluminum 3003 H14 /1100 H14 is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Roll of Aluminum 3003 H14 /1100 H14 is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of the Roll of Aluminum 3003 H14 /1100 H14:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Roll of Aluminum 3003 H14 /1100 H14

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-100mm

Width: 30mm-1700mm

4. Production of Roll of Aluminum 3003 H14 /1100 H14

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q:Can aluminum coils be recycled multiple times?

- Yes, aluminum coils can be recycled multiple times. Aluminum is a highly recyclable material, and the recycling process does not degrade its quality. This means that aluminum coils can be melted down and reformed into new coils multiple times without any loss in their performance or properties. Recycling aluminum not only helps to conserve natural resources but also saves energy compared to producing new aluminum from raw materials. Therefore, aluminum coils are a sustainable and environmentally friendly choice that can be recycled multiple times.

- Q:What is the cost-effectiveness of using aluminum coils compared to other materials?

- The cost-effectiveness of using aluminum coils compared to other materials depends on various factors such as the application, lifespan, and initial cost. Aluminum coils are widely used in various industries including construction, automotive, and HVAC due to their lightweight, corrosion resistance, and excellent thermal conductivity. These qualities make them a cost-effective choice in many applications. When compared to other materials like copper or steel, aluminum coils are generally more affordable. The initial cost of aluminum coils is typically lower, making them a cost-effective option for those working within a budget. Moreover, aluminum coils have a longer lifespan compared to some other materials. They are resistant to corrosion, which means they can withstand harsh environments, reducing the need for frequent replacements. This longevity can result in long-term cost savings. Additionally, aluminum is highly recyclable, making it environmentally friendly. The recycling process for aluminum requires significantly less energy compared to mining and refining new materials. This aspect further contributes to the cost-effectiveness of using aluminum coils. However, it is important to note that in certain applications, other materials may be more suitable. For example, copper coils are known for their superior heat transfer properties, making them ideal for specific HVAC systems where efficiency is crucial. In conclusion, the cost-effectiveness of using aluminum coils compared to other materials depends on the specific requirements of the application. While aluminum coils generally offer affordability, longevity, and recyclability, it is essential to consider factors such as heat transfer, system efficiency, and initial investment to determine the most cost-effective option for a particular project.

- Q:How are aluminum coils transported and delivered?

- Aluminum coils are typically transported and delivered through a combination of road, rail, and sea transportation methods. The specific mode of transportation will depend on various factors, including the distance between the manufacturing facility and the destination, the quantity of coils being transported, and the urgency of the delivery. For shorter distances, aluminum coils are commonly transported by road. Specialized trucks equipped with flatbed trailers or coil carriers are used to ensure safe and secure transportation. These trucks are designed with features like adjustable cradles or coil pads that prevent the coils from rolling or shifting during transit. When it comes to longer distances, rail transportation is often employed. Coils are loaded onto railcars, which can accommodate a significant number of coils depending on their size and weight. Rail transport offers the advantage of being more cost-effective and environmentally friendly compared to road transportation for long-haul journeys. In cases where aluminum coils need to be transported overseas or to another continent, sea transportation is the preferred option. Coils are carefully packed into shipping containers, ensuring they are adequately protected from potential damage during transit. These containers are then loaded onto cargo ships, which offer the necessary capacity and stability to transport large quantities of coils across long distances. Regardless of the mode of transportation, it is crucial to handle aluminum coils with care to prevent any damage or deformation. Special attention is given to protecting the coils from excessive vibration, impact, or exposure to adverse weather conditions. To ensure proper delivery, logistics companies often employ tracking systems that allow them to monitor the location and condition of the coils throughout the transportation process. Overall, the transportation and delivery of aluminum coils involve a well-coordinated logistics network to ensure the coils reach their destination in a timely and efficient manner while minimizing the risk of damage.

- Q:i know aluminum nitrate will dissociate, and also that there is no way that the nitrate will react to make the solution basic or neutral. But what about the aluminum ion? Does it take OH- from water to make [Al(OH)4]- and make the solution acidic? Does it somehow take protons and make a basic solution? My teacher said its not neutral, so I'm leaning towards an acidic solution. Thanks!

- Aluminum nitrate is the salt produced by the reaction of aluminum hydroxide and nitric acid. Nitric acid is a strong acid. Aluminum hydroxide is a realtively weak base. So the salt will be acidic.

- Q:How to identify the quality of color coated aluminum coil and sheet?

- Color coated aluminum coil is a kind of aluminum coil. As for qualified color coated aluminum coil, the surface has no impression, holiday and damage through the coating, and also no ripple, scratch and swell. All these are easy to see. However, the most important is the color difference of the color coated aluminum coil which is not obvious but will influence the decoration effect. Now the surface of curtain wall aluminum sheet will also be treated with electrostatic spraying. The power coating materials can have dozens of colors and realize good decorative effect, with polyurethane, polyethylene expansion resin and epoxy resin as raw materials, high color retention pigment as auxiliaries.

- Q:Can aluminum coils be used in automotive heat shields?

- Yes, aluminum coils can be used in automotive heat shields. Aluminum is a commonly used material in the manufacturing of heat shields due to its excellent heat resistance and lightweight properties. Aluminum coils can be formed and shaped into the desired design, allowing for easy installation and customization in automotive applications. Additionally, aluminum has high thermal conductivity, which helps to dissipate heat effectively, making it an ideal choice for heat shields in vehicles.

- Q:Can aluminum coils be used in power generation facilities?

- Aluminum coils are indeed suitable for use in power generation facilities. Aluminum, being a highly conductive material, offers numerous benefits for power generation applications. Its exceptional thermal conductivity allows for efficient heat transfer from the coils, a critical factor in cooling systems within power generation facilities. Moreover, aluminum's lightweight nature simplifies handling and installation, setting it apart from metals such as copper. This lightweight attribute also contributes to cost savings by reducing overall equipment weight. Additionally, aluminum's corrosion resistance is particularly valuable in power generation facilities, which frequently operate in challenging environments. In conclusion, considering their conductivity, thermal efficiency, lightweight nature, and corrosion resistance, aluminum coils present a feasible choice for power generation facilities.

- Q:I have been trying to make some thermite for a while now, and I haven't had much success. I have tried using iron oxide and that didn't work. then I tried using manganese dioxide, also without success. I'm pretty sure I have the right proportions for each of the corresponding oxides, but it just isn't working. I am using magnesium ribbon to light it.The aluminum I am using is the byproduct of me trying to cut a block of aluminum with a hacksaw (best way I have available to cut it) and there is a lot of aluminum powder that is being made. But i'm not sure if it is fine enough to be effective. I don't have an etch-a -sketch so that's not an option. I know that it has to be fairly fine grained, but how small do the particles need to be?FOR EVERYONE WHO IS GOING TO TRY AND TELL ME THAT MAKING THERMITE IS DANGEROUS OR SOMETHING ALONG THOSE LINES......DONT!!!!!!!!.......... IM NOT GOING TO LISTEN SO SAVE YOURSELF THE TYPING AND ME THE READING

- In 35+ years of demonstrating the thermite reaction, I have used fine aluminium powder to quite visible small bits. The proportions don't seem too critical, but try and keep near the amounts represented by the balanced eqtn. The difficult bit is getting the wretched stuff to ignite. With some mixes several strands of magnesium ribbon as fuse still wouldn't get it to ignite. I found a pile of 'ignition powder' at the base of the Mg often helped. There was a good commercial one available in the UK but I often made one up, main ingredients barium peroxide and magnesium powder, about 50/50. Needless to say, ignite with this mix where you won't breathe any nasty fumes. To get a good result, if I didn't use a proper crucible, I shaped one of Al foil about the capacity of 2-3 eggcups. This was put on sand in a big coffee tin, then more sand added to fill round the sides. This would give a good amount of iron. I once made the mistake of rushing in too quickly to get out the red hot iron.... and completely melted the ends of a large pair of Nickel tongs!

- Q:What are the potential health risks associated with aluminum coils?

- The potential health risks associated with aluminum coils primarily revolve around exposure to aluminum particles, which can occur through inhalation or ingestion. Prolonged exposure to these particles may contribute to respiratory issues such as asthma and lung inflammation. Additionally, there is some concern about the potential connection between aluminum exposure and Alzheimer's disease, although more research is needed to establish a conclusive link. To mitigate these risks, it is advisable to ensure proper ventilation, minimize direct contact with aluminum surfaces, and maintain good cleaning practices to reduce the likelihood of particle release.

- Q:Are there any safety concerns when handling aluminum coils?

- Yes, there are safety concerns when handling aluminum coils. Aluminum coils can be sharp and may cause cuts or injuries if mishandled. Additionally, aluminum coils may contain sharp edges or burrs which can pose a risk of injury. It is important to handle them with proper protective equipment such as gloves and ensure safe lifting techniques to avoid any accidents.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roll of Aluminum 3003 H14 /1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords