Hot Rolled Carbon Steel Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Product Advantages:

OKorder's Square Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Grade: Q195, Q235, Q345

2. Diameter: 6mm-150mm

3. Length: 6m, 9m, 12m or as customer’s request

4. Tolerance: Within ±5% for weight; ±2mm for diameter

5. Note: The price can be better is the quantity is good

6. Chemical composition

Alloy No | Element (%) | ||||

C | Mn | S | P | Si | |

Q195 | 0.06-0.12 | 0.25 | ≤0.05 | ≤0.045 | ≤0.3 |

Q235 | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Q345 | ≤0.2 | 1.00-1.60 | ≤0.045 | ≤0.045 | ≤0.55 |

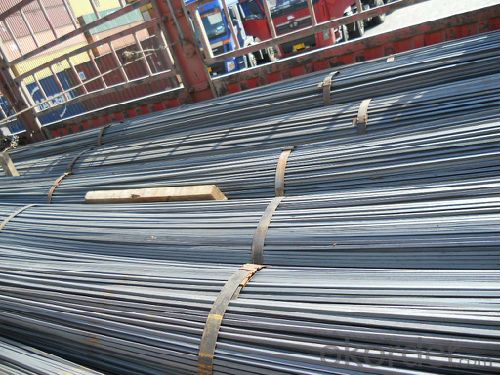

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q:How do you use a steel square to determine the width of a cabinet door?

- In order to determine the width of a cabinet door using a steel square, it is crucial to ensure the proper alignment and perpendicularity of the steel square with the door's edge. Begin by positioning the steel square against the door's edge, ensuring that one of its arms is in complete alignment with either the top or bottom of the door. Next, utilize the other arm of the square to extend across the face of the door, thereby measuring its width. It is imperative to guarantee that the square is perfectly aligned with the edge and that the arm remains parallel to the door's edge. Once you have obtained the desired width measurement, accurately mark it on the door for precise cutting or future reference. Remember to employ the square's edge as a guide for meticulous measurements, thus ensuring the door attains a perfect squared shape.

- Q:Can a steel square be used for masonry work?

- No, a steel square is not typically used for masonry work. Masonry work requires specialized tools such as trowels, levels, and masonry hammers, which are better suited for the specific tasks involved in working with bricks, stones, or concrete blocks.

- Q:How do you use a steel square to find the rise and run of stairs?

- To use a steel square to find the rise and run of stairs, you would first measure and mark the desired rise and run on the square's blade. Then, place the square's tongue along the rise and run of the stairs, ensuring it is level. By aligning the markings on the blade with the edge of the stairs, you can accurately determine the rise and run measurements needed for constructing the stairs.

- Q:Can a steel square be used for drywall patching?

- Yes, a steel square can be used for drywall patching. It can be used to measure and mark the dimensions of the patch accurately, ensuring a precise fit. Additionally, the straight edge of a steel square can be used as a guide for cutting the drywall patch.

- Q:How do you use a steel square to determine the slope of a deck?

- To determine the slope of a deck using a steel square, you can follow these steps: 1. Start by finding a flat and level surface near the deck. This could be the ground or a nearby table. 2. Place the steel square on the flat surface, ensuring that it is completely level. You can use a bubble level to confirm this. 3. Take the steel square and position it against a vertical post or wall of the deck. Ensure that one side of the square is flush against the post while the other side extends outwards towards the edge of the deck. 4. Once the steel square is properly positioned, use a carpenter's level or a plumb bob to determine the vertical line. This will help you establish a reference point for measuring the slope. 5. From the vertical line, measure the distance between the horizontal edge of the steel square and the deck's surface. You can use a tape measure or ruler for this step. 6. Make note of the measurement, as this will indicate the rise or drop in height over a given distance. 7. To determine the slope, divide the rise or drop in height by the distance measured in the previous step. This will give you the slope ratio or gradient of the deck. For example, if you measured a 1-inch rise over a 12-inch distance, the slope would be 1:12 or 1/12. By following these steps and using a steel square along with a level, you can accurately determine the slope of a deck. This information is essential for ensuring proper drainage and preventing water pooling, as well as maintaining the structural integrity of the deck.

- Q:What are some common markings found on a steel square?

- Some common markings found on a steel square include inch and metric scales, degree measurements, and angles such as 45 and 90 degrees.

- Q:How do you use a steel square to measure the height of a countertop?

- To measure the height of a countertop using a steel square, follow these steps: 1. First, ensure that both the countertop and the steel square are clean and free of debris. 2. Position the steel square vertically against the countertop's edge, making sure it is flush with the surface. 3. Firmly hold the square in place with one hand. 4. Utilize a tape measure or ruler to determine the distance between the floor and the bottom of the steel square. This measurement will provide the countertop's height. 5. Take accurate and precise measurements, ensuring that the steel square remains straight against the countertop's edge for an accurate reading. 6. Repeat the measurement process at various points along the countertop's edge for consistency. This is especially crucial if the countertop is uneven or if you need to measure different sections of it. 7. Once all the necessary measurements are taken, calculate the average height of the countertop by adding them up and dividing by the total number of measurements. Using a steel square to measure a countertop's height is a straightforward and reliable method that yields accurate results. Remember to be cautious and focused while taking measurements to achieve the best possible outcome.

- Q:Can a steel square be used for metalworking tasks?

- A steel square has multiple applications in metalworking. Engineer's squares or machinist's squares, also referred to as steel squares, are precision tools extensively used in metalworking. These tools are typically made from hardened steel and possess precise right angles, which make them perfect for verifying and marking 90-degree angles in metal fabrication, welding, and machining procedures. Steel squares are frequently employed to ensure accuracy and alignment of metal components during layout, layout marking, scribing, and measuring tasks. Moreover, they can be utilized to examine the flatness and straightness of metal surfaces, as well as to square up workpieces during cutting or milling. Overall, steel squares are essential tools in the field of metalworking, providing valuable assistance in achieving precision and quality in a variety of metal-related tasks.

- Q:How do you use a steel square to measure and mark perpendicular lines?

- To use a steel square to measure and mark perpendicular lines, align one edge of the square with the reference line or edge. Then, ensure that the other edge is perpendicular to the reference line by checking if it forms a 90-degree angle. Once the square is properly aligned, use a pencil to mark the perpendicular line along the edge of the square.

- Q:Can a steel square be used for checking the levelness of countertops?

- No, a steel square cannot be used for checking the levelness of countertops. A steel square is primarily used for measuring angles and ensuring the accuracy of right angles. To check the levelness of countertops, a level tool should be used. A level is a device with a bubble vial filled with liquid that allows you to determine if a surface is perfectly horizontal or vertical. This is important for countertops to ensure that they are level and provide a stable and even surface.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Carbon Steel Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords