Aluminium Plate And Aluminium Sheet And Slab

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description.

Our CNBM International have the new-advanced production line, which can produce the aluminum sheet, aluminum coil, aluminum chekcered sheet and also the aluminum mirror sheet, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

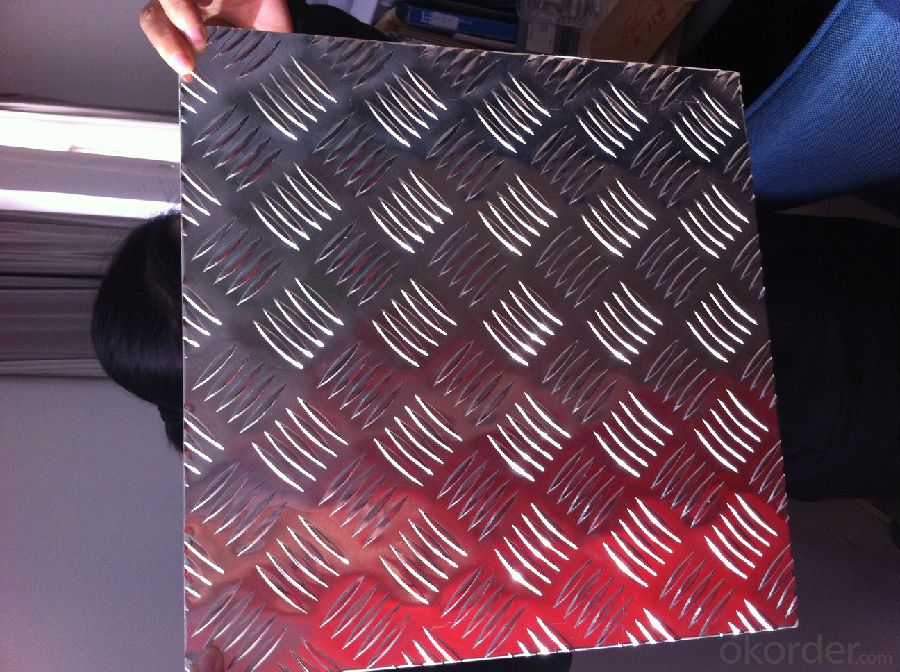

3. Image.

4. Product detailed sizes:

1219mm*2438mm,1250mm*2500mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q:How do aluminum sheets perform in terms of electrical insulation?

- Aluminum sheets do not possess notable electrical insulation properties. Being a highly conductive metal, aluminum enables the easy flow of electric current. Consequently, effective electrical insulation cannot be attained with aluminum sheets. In situations where electrical insulation is necessary, alternative materials like plastics or ceramics would be more appropriate choices.

- Q:I'm working on a costume that's entirely made of cardboard (it's a giant robot), and I was wondering What's the best way to1 turn Soda cans into aluminum sheeting2: attach the aluminum everywhere on the robot3. Attach the aluminum to the aluminumThank you in advance.

- Why not heavy duty aluminum foil glued to cardboard? that would look a lot better than patched up pieces of aluminum from tin cans. How would you connect the chunks of aluminum together? and remove the label. Note that soda cans have a coating of plastic on the inside. I don't see any easy way to attach the bits of aluminum from tin cans together, and remove the painted on labels. It would look just like that, pieces of cans glued together. In stead of cardboard you could use foam board which is lighter and more rigid.

- Q:Does anyone know why Mercury -(Thimerosal) is used in Flu Vaccinations and where Mercuryisnot used Aluminium in other vaccines ? While these are known to be toxic metals, can these cause headaches, severe hot burning heads and or Sinusitus ?

- Toxicity is about dose. The dose of mercury in the flu vaccine is minute and cannot possibly contribute to mercury poisoning. In any case, Thimerosal converts to ethylmercury in the body which is quickly broken down and excreted - unlike methylmercury which is the mercury you are thinking about. A tuna fish sandwich will give you more mercury than any vaccine. Thimerosal is a preservative basically, which is why it is added to the multi-dose vial. If you are that paranoid about it, ask for the single dose vial to be used.

- Q:What is the hardness of aluminum sheets?

- The hardness of aluminum sheets may differ based on the particular alloy and temper it has undergone processing to. Aluminum alloys are usually evaluated using the Rockwell hardness scale or the Brinell hardness scale. Typically, pure aluminum exhibits a low hardness rating, approximately 20-30 on the Rockwell B scale, whereas certain aluminum alloys can achieve a hardness level of up to 70 on the Rockwell C scale. However, it is essential to recognize that the hardness of aluminum can be further adjusted through different heat treatment methods, like annealing or tempering, which can have a significant effect on its ultimate hardness.

- Q:What are the different methods of surface preparation for aluminum sheet?

- Depending on the desired finish and purpose, there are various approaches to preparing aluminum sheet surfaces. 1. Chemical Cleaning: To eliminate dirt, grease, and contaminants, chemical solutions are employed. The sheet is typically soaked in the cleaning solution and thoroughly rinsed to ensure complete removal of any residues. 2. Mechanical Cleaning: Imperfections or coatings are removed through mechanical processes like sanding, grinding, or brushing. Abrasive materials or tools are used for sanding or grinding, while wire brushes are employed for brushing. 3. Etching: A textured finish that enhances adhesion for subsequent coatings or finishes is achieved through the application of acid or alkaline solutions to the aluminum sheet. This process removes a thin layer of the metal, creating a rough surface. 4. Anodizing: By immersing the sheet in an electrolytic solution and passing an electric current through it, an oxide layer is formed on the aluminum sheet. Anodizing not only improves the appearance but also provides protection against corrosion. 5. Conversion Coating: The surface of the aluminum sheet is converted into a more corrosion-resistant material through chemical processes like chromate or phosphate conversion coating. These coatings offer additional protection and improve the bonding of subsequent coatings. Each method of surface preparation for aluminum sheet has distinct advantages and is selected based on specific requirements. It is crucial to choose the appropriate method to ensure proper adhesion of coatings and finishes, as well as to enhance the overall durability and appearance of the aluminum sheet.

- Q:What are the different methods of surface coating for aluminum sheets?

- Aluminum sheets can be coated using various methods, each with its own unique benefits and applications. Some commonly used methods include: 1. Anodizing: By immersing aluminum in an electrolytic solution, a protective oxide layer is formed on its surface. This process enhances corrosion resistance, durability, and can be used for decorative finishes. 2. Powder coating: Dry powder is applied to the aluminum surface and then cured through heating. This method provides a durable and attractive finish, with excellent resistance to abrasion, chemicals, and UV rays. 3. Painting: Conventional liquid paints can be used to coat aluminum sheets, allowing for customization and offering good corrosion protection. However, this method may not be as durable as others. 4. Cladding: A protective layer, such as stainless steel or other metals, is bonded onto the surface of the aluminum sheet. This provides superior protection against corrosion, impact, and extreme weather conditions. 5. Laminating: A thin layer of protective material, such as PVC or PET film, is applied to the aluminum sheet. This enhances resistance to scratching, staining, and fading, making it suitable for applications requiring long-term durability. 6. Chemical conversion coating: The aluminum surface is treated with a chemical solution to create a thin, protective layer. For example, chromate conversion coating enhances corrosion resistance and improves paint adhesion. 7. Electrophoretic deposition (EPD): The aluminum sheet is immersed in a water-based paint solution, and an electric current is used to deposit the paint particles onto the surface. This method provides uniform coating thickness and excellent corrosion resistance. Each of these methods has specific advantages and is suitable for different applications. The choice of method depends on the desired properties, aesthetics, and intended use of the aluminum sheets.

- Q:Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

- Q:As for graphite and aluminum sheet, which one has a better thermal conductivity?

- Aluminum sheet has a better thermal conductivity, because metal is good conductor of heat, graphite is n't metal.

- Q:What are the different manufacturing methods for aluminum sheets?

- There are several manufacturing methods for aluminum sheets, including rolling, extrusion, casting, and forging.

- Q:What are the different surface finishes available for aluminum sheets?

- Some of the different surface finishes available for aluminum sheets are mill finish, brushed finish, anodized finish, and embossed finish. Mill finish is the natural appearance of the aluminum without any additional treatment. Brushed finish involves brushing the surface to create a textured appearance. Anodized finish involves an electrolytic process that forms a protective layer on the surface and can be colored. Embossed finish involves creating patterns or designs on the surface using pressure or heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Plate And Aluminium Sheet And Slab

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords