High Rib Lath

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

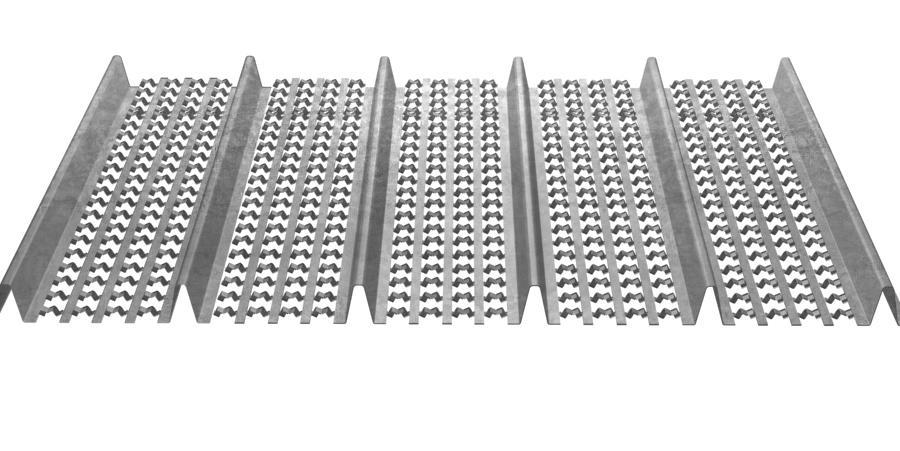

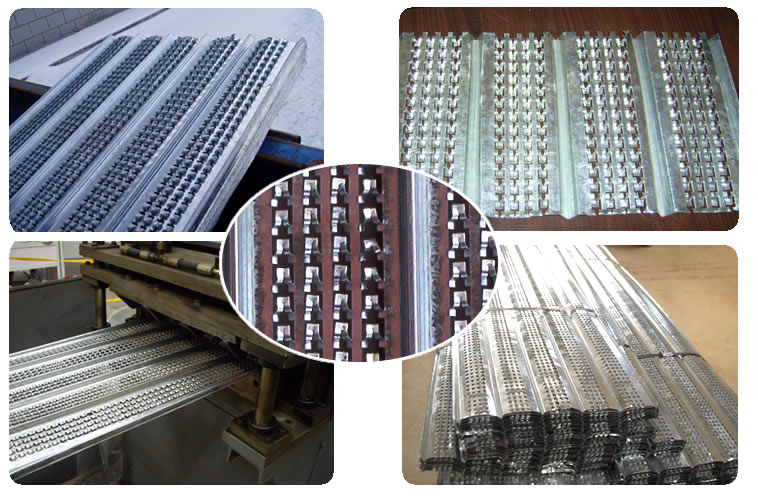

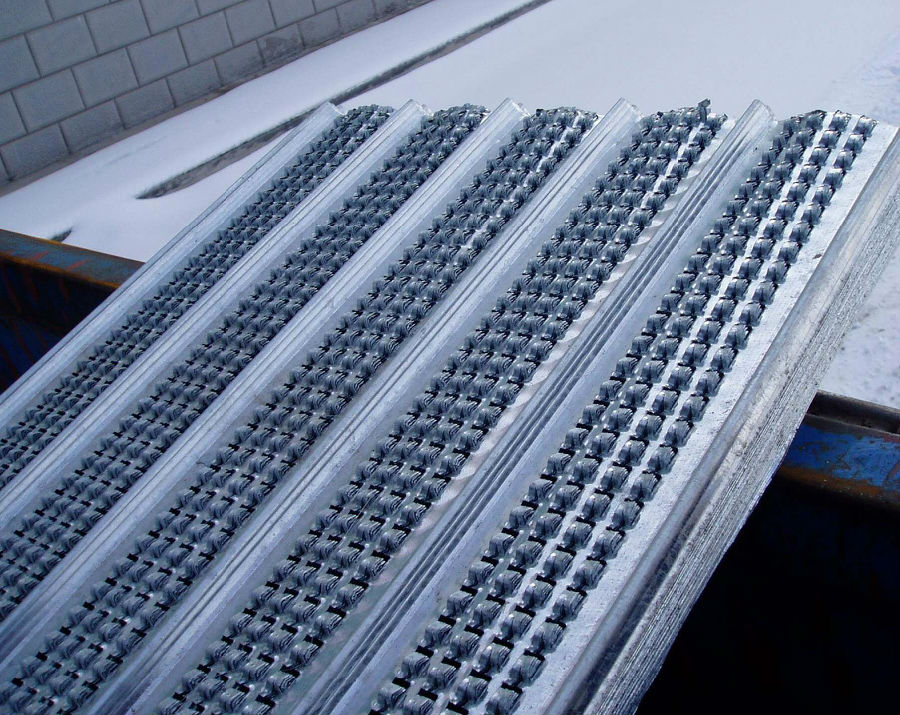

High Ribbed Formwork is made from hot dipped galvanized steel sheets. The mesh and ribs are formed on machines which first cut and press the mesh and then roll form the ribs. At the same time the material is stretched to form an expanded mesh.

Matal Rib Lath/High Rib Lath

Concreting mould mesh

Material: hot-dipped galvanized steel sheet

Thickness: 0.1-0.5mm

Size: 450x2000mm

ISO9001 certific

Feature: Because of its meshes and U patterns, it has better anti-stress capability and forming flexibility than normal metal lath. This product has excellent engineering quality, construction security

Application:

1).Construction formwork mesh has very good engineering quality and construction security;

2).Construction formwork mesh as the concrete permanent assembly

free sheet is much convenient for engineering design and processing;

3).Construction formwork mesh is widely used in tunnels,bridges and valve system and so on

to make the process of construction much more fast and stable.

Specification:

Thickness (mm) | Weight (kg) | Width (mm) | Length (mm) | Area (m2) |

0.2 | 1.70 | 445 | 2200 | 0.99 |

0.25 | 2.10 | 445 | 2200 | 0.99 |

0.30 | 2.60 | 445 | 2200 | 0.99 |

0.35 | 3.00 | 445 | 2200 | 0.99 |

0.40 | 3.40 | 450 | 2200 | 0.99 |

0.45 | 3.80 | 450 | 2200 | 0.99 |

0.50 | 4.20 | 450 | 2200 | 0.99 |

0.55 | 4.60 | 450 | 2200 | 0.99 |

0.60 | 5.00 | 450 | 2200 | 0.99 |

- Q:Can steel wire mesh withstand high temperatures?

- Yes, steel wire mesh can withstand high temperatures. Steel wire mesh is typically made from stainless steel or carbon steel, both of which have high melting points and excellent heat resistance properties. Stainless steel wire mesh can withstand temperatures up to 800-900 degrees Celsius (1472-1652 degrees Fahrenheit), while carbon steel wire mesh can withstand temperatures up to 450-500 degrees Celsius (842-932 degrees Fahrenheit). This makes steel wire mesh suitable for applications that involve high temperatures, such as industrial furnaces, kilns, and heat treatment processes. However, it is important to note that the specific temperature resistance of steel wire mesh may vary depending on the grade and quality of the steel used, as well as the specific manufacturing process. Therefore, it is recommended to consult the manufacturer or supplier for precise temperature ratings and suitability for specific high-temperature applications.

- Q:Is steel wire mesh suitable for packaging applications?

- Yes, steel wire mesh is suitable for packaging applications. It provides a strong and durable solution for packaging various items, ensuring they are securely contained and protected during transportation and storage. The mesh design allows for visibility and ventilation, making it suitable for products that require airflow or need to be easily identified. Additionally, steel wire mesh is resistant to corrosion and can withstand heavy loads, making it ideal for packaging applications in various industries.

- Q:How does the roll size affect the ease of installation of steel wire mesh?

- The roll size of steel wire mesh can have an impact on the ease of its installation. Generally, larger roll sizes can make the installation process more convenient and efficient. When working with a larger roll size, there is typically less time spent on joining multiple smaller rolls together, which can be time-consuming and require additional tools or equipment. Moreover, larger roll sizes often mean that longer stretches of wire mesh can be installed without interruptions, resulting in a smoother and more seamless installation. This can be particularly beneficial when covering larger areas or when the wire mesh needs to be installed continuously without any breaks or joints. Additionally, larger rolls of steel wire mesh are often heavier and more robust, which can make them easier to handle and manipulate during installation. The increased weight and stability of larger rolls can prevent them from shifting or moving around excessively, ensuring that the mesh remains in place and properly aligned during the installation process. However, it is worth noting that the specific ease of installation may also depend on other factors such as the installation technique, the terrain or surface where the wire mesh is being installed, and the experience or skills of the installer. Therefore, while larger roll sizes generally offer advantages in terms of ease of installation, it is important to consider these other factors as well.

- Q:Can steel wire mesh be used for industrial filters?

- Industrial filters can utilize steel wire mesh, which is a versatile material offering numerous advantages. Renowned for its durability and high tensile strength, it is capable of enduring harsh conditions and delivering long-lasting performance. Steel wire mesh filters find widespread use in the oil and gas, chemical processing, mining, and food and beverage industries. They effectively separate solids, contaminants, and impurities from liquids, gases, and air. Customizable mesh sizes and filtration ratings ensure precise filtration and separation as per specific requirements. Furthermore, steel wire mesh filters exhibit exceptional resistance to corrosion, heat, and pressure, making them suitable for demanding industrial settings. They withstand high temperatures and aggressive chemicals while maintaining their structural integrity, ensuring optimal filtration performance. Moreover, steel wire mesh filters are easily cleaned and maintained, reducing downtime and operational expenses. Often designed with a removable element or a backwashing mechanism, they allow for efficient cleaning and reusability. In conclusion, steel wire mesh is a dependable and efficient material for industrial filters. Its strength, durability, resistance to corrosion and heat, and customizable filtration capabilities make it an ideal choice for diverse industrial applications.

- Q:What are the different opening configurations available for steel wire mesh?

- There are several opening configurations available for steel wire mesh, including square, rectangular, diamond, hexagonal, and slotted openings. These configurations can be chosen based on the specific application and desired functionality of the steel wire mesh.

- Q:What are the different load-bearing capacities available for steel wire mesh?

- The load-bearing capacity of steel wire mesh can vary depending on several factors such as the thickness and diameter of the wire, the spacing between the wires, and the overall size and configuration of the mesh. Steel wire mesh is commonly available in different load-bearing capacities to suit various applications and requirements. For lighter applications, such as fencing or decorative purposes, steel wire mesh with lower load-bearing capacities may be sufficient. These meshes typically have thinner wires and wider spacing between them, allowing for easier installation and offering a lighter weight solution. In contrast, heavy-duty applications, such as industrial or construction projects, may require steel wire mesh with higher load-bearing capacities. These meshes are usually made with thicker wires and narrower spacing between them, providing increased strength and stability to withstand heavier loads and stresses. Load-bearing capacities for steel wire mesh can range from a few hundred pounds per square foot to several thousand pounds per square foot. It is important to consider the specific requirements of the project and consult with manufacturers or suppliers to determine the most suitable load-bearing capacity for the intended application. Additionally, it is worth noting that load-bearing capacities can also be influenced by the type of steel used, the manufacturing process, and any additional treatments or coatings applied to the mesh. Therefore, it is advisable to obtain detailed technical specifications and performance data from the manufacturer to ensure the chosen steel wire mesh meets the desired load-bearing requirements.

- Q:What are the different surface textures available for steel wire mesh?

- There are various surface textures available for steel wire mesh, including plain, galvanized, PVC coated, epoxy coated, and stainless steel.

- Q:Can steel wire mesh be used for moisture control?

- Steel wire mesh can be used as a component in moisture control systems. While it may not directly control moisture, it can be used in various applications to support moisture control efforts. For example, steel wire mesh can be used as a reinforcement in concrete structures such as retaining walls or foundation slabs, which can help prevent moisture infiltration. Additionally, steel wire mesh can be used in drainage systems to facilitate the flow of excess moisture away from structures. Furthermore, steel wire mesh can also be used as a barrier or protective cover to prevent moisture from entering certain areas, such as crawl spaces or ventilation systems. However, it is important to note that steel wire mesh alone is not a complete solution for moisture control and should be used in conjunction with other appropriate measures for effective moisture management.

- Q:How is steel wire mesh used in reinforcement of manufacturing facilities?

- Steel wire mesh is commonly used in the reinforcement of manufacturing facilities for various purposes. One of the primary uses is in concrete reinforcement. Steel wire mesh is embedded within the concrete structure to enhance its structural integrity and increase its load-bearing capacity. This is particularly crucial in manufacturing facilities where heavy machinery and equipment are utilized, as it helps prevent cracking, sagging, and failure of concrete structures. Steel wire mesh is also used in the reinforcement of walls and partitions within manufacturing facilities. It provides added strength and stability, ensuring that the walls can withstand external forces and pressures. This is important in facilities where there are high vibrations or potential impacts, such as from heavy machinery or forklift movements. Moreover, steel wire mesh is used for safety purposes in manufacturing facilities. It can be installed as a protective barrier around hazardous areas or machinery to prevent accidents and injuries. Steel wire mesh acts as a physical barrier, allowing visibility and ventilation while restricting access to dangerous areas. Additionally, steel wire mesh is utilized in the reinforcement of storage racks and shelves within manufacturing facilities. By incorporating wire mesh panels or decking, the structural integrity of these storage systems is improved, allowing for the safe and efficient storage of heavy items and materials. Overall, steel wire mesh is an essential component in the reinforcement of manufacturing facilities. Its versatility, durability, and strength make it an ideal choice for enhancing the structural integrity of concrete, walls, partitions, storage systems, and providing safety measures, ensuring a safe and efficient working environment in manufacturing facilities.

- Q:What are the different wire mesh dimensions available in steel wire mesh?

- Steel wire mesh is available in a wide range of dimensions to suit various applications and requirements. The dimensions of steel wire mesh typically refer to the spacing between the wires and the diameter of the wires used. The spacing between the wires, also known as the mesh size or mesh opening, can vary significantly. Common mesh sizes include 1/4 inch, 1/2 inch, 1 inch, 2 inches, and 4 inches. However, there are also finer meshes available with smaller openings, such as 1/8 inch or even smaller. On the other hand, larger mesh sizes with wider openings may also be used for specific purposes. The diameter of the wires used in steel wire mesh can also vary depending on the strength and durability required. Common wire diameters for steel wire mesh range from 0.5mm to 5mm. Thicker wires are typically used for heavy-duty applications where strength and stability are crucial, while thinner wires are suitable for lighter applications. Moreover, steel wire mesh can come in various forms, such as woven wire mesh, welded wire mesh, and expanded metal mesh. Each of these forms has its own unique dimensions and characteristics. In summary, the dimensions available in steel wire mesh vary in terms of the mesh size or spacing between wires and the diameter of the wires used. These dimensions can be customized to meet specific requirements, ensuring that steel wire mesh is versatile and adaptable for a wide range of applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Rib Lath

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products