1100 1050 2024 3003 5052 6061 6082 7021 Alloy 5052 Alloy Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

1.Alloy: 1100 1050 2024 2017 3003 5052 6061 6063 7075 7021 etc

2.Temper:O H112 H12 H14 H16 T3 T4 T6 T651 etc

3.Dimension based on customer requirements

4.Good quality choose us

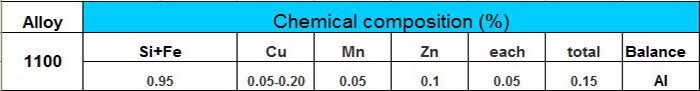

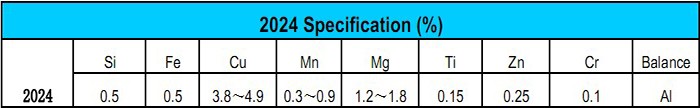

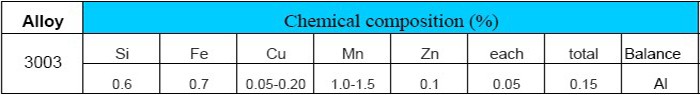

Chemical Composition:

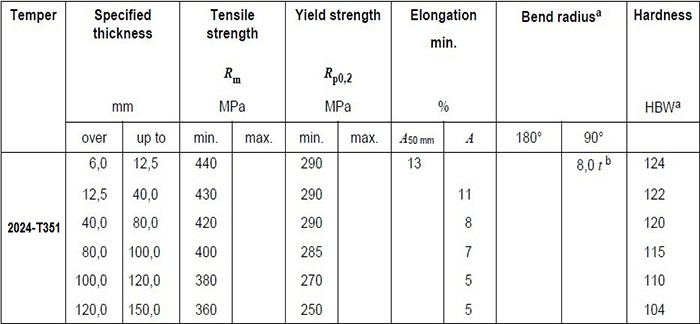

Technical Specification:

Packaging & Delivery

| Packaging Details: | Wooden Pallet, Wooden Case, As Customzed, etc. |

| Delivery Detail: | 15 to 25 days depends on actual order |

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

Company Information

Advanced equipment and strict management both contribute to the excellent quality of products. Our main products are all kinds of cold rolling and hot rolling aluminum sheet, coil, checkered plate, embossed plate, aluminum foil, aluminum disc, aluminum profile, painted aluminum sheet and coil. Our products have various size choices with thickness from 0.008mm to 350mm, width from 200mm to 2300mm and length below 12m. Our products are sold to all over the world, including South America, North America, Europe, Middle-East, South-East Asia, Africa etc and used in various fields such as construction, decoration, automobile, electronic, machinery, boat construction, aeronautics&astronautics, cookware, packing etc.

Adhering to the principle of “ Surviving with quality and developing with credibility”, CNBM hopes to work with all customers for a better future.

FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4) Why YONGHONG?

With us, you get most competitive price, guranteened quality with assured delivery time and after sales service

- Q:Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q:What is the tensile strength of 101 aluminum sheets?

- The tensile strength of 101 aluminum sheets can vary depending on various factors such as manufacturing process, heat treatment, and specific alloy composition. However, generally speaking, 101 aluminum sheets have a tensile strength of approximately 27,000 to 42,000 pounds per square inch (psi). It is important to note that this range is an approximation and actual tensile strength values may differ slightly. It is recommended to refer to the specific manufacturer's data sheet or conduct further testing to determine the precise tensile strength of 101 aluminum sheets.

- Q:I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q:What are the different joining methods for aluminum sheets?

- There are several joining methods for aluminum sheets, including welding, adhesive bonding, mechanical fastening, and soldering.

- Q:Can aluminum sheet be welded?

- Yes, aluminum sheet can be welded. Aluminum is a versatile metal that can be easily welded using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). However, welding aluminum requires special considerations due to its high thermal conductivity and low melting point compared to other metals. It is important to choose the appropriate welding process, filler material, and shielding gas to ensure a successful weld. Additionally, proper surface preparation, including cleaning and removing any oxide layer, is crucial for achieving a strong and durable weld in aluminum sheet.

- Q:Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks as they lack the necessary corrosion resistance for handling and storing chemicals.

- Q:Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, aluminum sheets are available in different finishes such as brushed and polished.

- Q:Can the aluminum sheets be used for manufacturing kitchen countertops?

- Certainly! Kitchen countertops can indeed be manufactured using aluminum sheets. Aluminum proves to be a versatile and durable material, displaying resistance against both corrosion and heat. Its lightweight nature and easy workability make it an ideal choice for crafting custom countertops in a variety of sizes and shapes. Moreover, aluminum countertops boast a contemporary and sleek appearance, while also being effortlessly cleanable and maintainable. Nevertheless, it is noteworthy that aluminum is comparatively softer when compared to other commonly utilized countertop materials like granite or quartz. Consequently, aluminum countertops may be more susceptible to scratches and dents. However, with proper care and maintenance, aluminum sheets can serve as a feasible alternative for producing kitchen countertops.

- Q:Can aluminum sheets be easily shaped or bent?

- Indeed, aluminum sheets possess a remarkable capability to be effortlessly molded or flexed. Renowned for its exceptional malleability and ductility, aluminum exhibits a remarkable propensity to be readily fashioned into diverse contours and curves. The manipulation of this versatile metal can be accomplished through an assortment of techniques, encompassing rolling, pressing, and even manual utilization of tools. Given its pliability, aluminum emerges as the preferred choice within industries such as automotive, aerospace, and construction, wherein the fabrication of intricate shapes and bends is a common necessity. Moreover, the lightweight nature and inherent resistance to corrosion further enhance aluminum's suitability for shaping and bending endeavors.

- Q:How do aluminum sheets perform in terms of sound insulation?

- Aluminum sheets are not well-known for their sound insulation properties. Due to their relatively low density and thinness, aluminum sheets do not provide substantial soundproofing capabilities. They are more commonly used in applications where their lightweight nature, corrosion resistance, and thermal conductivity are desired, rather than for their sound insulation properties. For effective sound insulation, other materials such as rubber, foam, or fiberglass are often preferred.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1100 1050 2024 3003 5052 6061 6082 7021 Alloy 5052 Alloy Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords