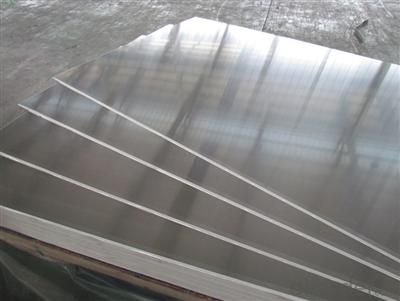

2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum sheet specifications:

1) Alloy : 1A99,2A12,2024,2219,2618,2A50,2A70,5A06,5083,6082,7075,7050, 7A85,7020 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 350mm

4) Width:20mm to 3300mm

5)Length: Accord to customer's requirements.

Reliable Quality,Reasonable Price and Good Service.

Any email will be replied with 24 hours. Thanks for your time!

6061 Aluminum plate/ aluminum thin sheet/ aluminum coil/ aluminum pipe application

The main alloy elements of 6061 alloy are Mg and Si and they form into Mg2Si. If it contains a certain amount of Mn and Cr, the bad effect of the iron can be neutralized. Sometimes you could also add a small amount of Cu and Zn to improve the strength of the alloy without decreasing its corrosion resistance obviously. Conductive material also contains a small amount of Cu which helps to counteract the bad effect of Ti and Fe on the electrical conductivity. In order to improve its cutting property, you could also add Pb and Bi. The alloy will has artificial aging hardening function when Mg2Si Solid soluble in aluminum.

6061-T651 is the main alloy elements of 6061 alloy. It is high quality aluminum products which are produced by heat treatment of pretensioning technique. Although its intensity cannot compare with 2XXX and 7XXX series, it has more magnesium and silicon alloy properties. It also has excellent process ability, good welding characteristics and plating properties, good corrosion resistance and high toughness. When you process it, there will be no deformation exist and no defects occur because of its dense material. What’s more, it is easy being polished and coloring the film and it has very good oxidation effect.

Representative applications include aerospace fixing device, electric appliance fixing device, communication field, automatic machinery parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder vehicles and so on.

Packaging & Delivery

| Packaging Details: | Bulk packaging for 6061 aluminum of do as you required |

| Delivery Detail: | 30 days for 6061 aluminum after you confirm the order |

- Q:why intact aluminum sheet stop quicker than pectinate one in the magnetic field?

- while swinging in the magnetic field, intact aluminum sheets will formulate inner eddy current,that is the annular induced current.eddy current will transform the mechanical energy into heat energy, which makes the aluminum sheet stop quickly.but pectinate aluminum sheet can't formulate intact eddy current, so intact aluminum sheet stop quicker than pectinate one.

- Q:Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q:What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q:What is the typical yield strength of aluminum sheets?

- The typical yield strength of aluminum sheets can vary depending on the specific alloy and temper, but it typically ranges from 15,000 to 40,000 psi (pounds per square inch).

- Q:im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- they can be made outta plastic or wood, prboably something else..but i can't thnk of it. ive had a plastic 1 and it still worked great..even though it was the ch eapest grinder in the store. so..personal preference really. gl

- Q:What are the different methods of surface treatment for aluminum sheets?

- Aluminum sheets can undergo various surface treatment methods, each with its own purpose and desired outcome. Popular methods include anodizing, chromate conversion coating, painting, and powder coating. Anodizing is commonly used to enhance the corrosion resistance and durability of aluminum sheets. This involves immersing the sheets in an electrolytic bath and applying an electric current to create a controlled oxide layer on the surface. The result is a protective and decorative coating that can be colored or sealed. Chromate conversion coating, also known as chemical conversion coating or chromating, applies a thin layer of chromate to the aluminum sheets. This method provides excellent corrosion resistance and improves paint adhesion. The coatings can be clear or have a yellowish or iridescent appearance. Painting is a widely used method to protect aluminum sheets and improve their visual appeal. Sheets are typically pre-treated with a primer to enhance adhesion, followed by the application of a topcoat for protection and color. Painted aluminum sheets come in a wide range of colors and finishes, suitable for various applications. Powder coating is an environmentally friendly and durable surface treatment for aluminum sheets. It involves electrostatically applying a dry powder onto the sheets, which is then cured in an oven. The powder melts and fuses to form a tough and attractive coating. Powder coating offers excellent resistance to corrosion, chemicals, and UV radiation. In addition to these methods, other techniques like polishing, buffing, and mechanical finishes can be employed to achieve specific desired appearances or surface qualities. Ultimately, the choice of surface treatment method for aluminum sheets depends on factors such as desired corrosion resistance, aesthetic requirements, environmental considerations, and the intended application of the sheets.

- Q:Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a non-toxic and non-reactive metal that does not leach harmful substances into food. It is widely used in the food industry for packaging, cooking utensils, and food storage containers. Additionally, aluminum exhibits excellent heat conductivity and can be easily cleaned, making it a popular choice for food-related applications.

- Q:How do you prevent distortion of aluminum sheets during welding?

- Distortion of aluminum sheets during welding can be prevented by implementing several measures. Firstly, utilizing proper welding techniques such as using appropriate heat input, controlling the welding speed, and using a suitable welding process can minimize distortion. Additionally, employing proper fixturing and clamping techniques to secure the sheets in place during welding can help maintain their shape. Pre-heating or post-weld heat treatment can also be employed to alleviate residual stresses and minimize distortion. Lastly, selecting the right filler material and adjusting its composition can aid in reducing distortion during the welding process.

- Q:Are aluminum sheets resistant to UV rays?

- Yes, aluminum sheets are generally resistant to UV rays.

- Q:Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Spray Painting Aluminum

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords