Plain Aluminium Sheets for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Plain Aluminium Sheets for Different Usages

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminum Sheets are widely used in curtain walls, roofing, decoration, boats, airframes, instrument panels, etc.

2.Main Features of Plain Aluminium Sheets for Different Usages

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

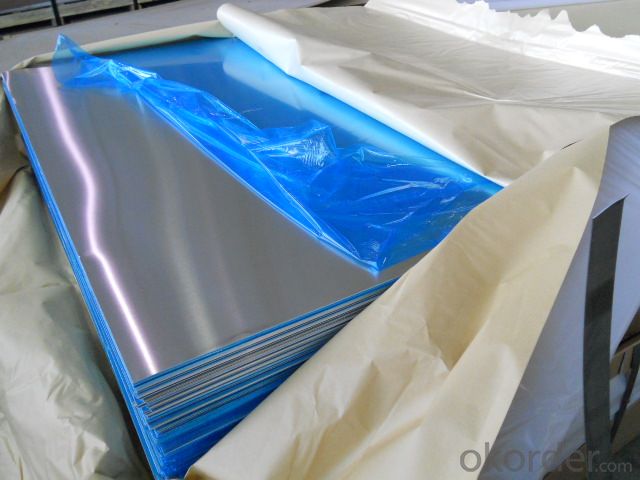

3. Plain Aluminium Sheets for Different Usages Images

4.Specification of Plain Aluminium Sheets for Different Usages

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put orderin production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium Coils?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:What are the different packaging options available for aluminum sheets during transportation?

- To ensure the safety and intactness of aluminum sheets during transportation, various packaging options are available. Some commonly employed choices are: 1. Wooden Crates: Strong and durable wooden crates offer formidable protection against impacts and rough handling. These crates can be tailored to the size and weight of the sheets. 2. Cardboard Boxes: For smaller quantities or sheets of smaller sizes, cardboard boxes are a popular option. The sheets are stacked and securely packed inside the boxes, which are then sealed to prevent movement or damage during transit. 3. Pallets: Wooden or plastic platforms called pallets provide convenient handling and transportation. The sheets are stacked and fastened to the pallets using straps, ensuring stability and protection during shipping. 4. Stretch Wrap: Another alternative is to tightly wrap the aluminum sheets together using a plastic film. This stretch wrap secures the sheets in place, shielding them from scratches and minor damages. 5. Protective Film: It is common practice to apply a protective film on the surface of the aluminum sheets before packaging. This film acts as a barrier, safeguarding against moisture, dust, and scratches during transportation. 6. Edge Protectors: To prevent damage to the edges of the aluminum sheets, edge protectors made of plastic or cardboard can be used. These protectors absorb impacts, ensuring the sheets remain intact. 7. Customized Packaging: Depending on the specific requirements and transportation method, customized packaging solutions can be devised. Foam inserts, dividers, or additional cushioning materials can be utilized to provide maximum protection during transit. Choosing the appropriate packaging option is crucial and should be based on factors such as size, weight, fragility of the aluminum sheets, mode of transportation, and distance to be traveled. Proper packaging is paramount in preventing damage and ensuring the sheets arrive at their destination in optimal condition.

- Q:the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q:Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q:Are aluminum sheets suitable for pharmaceutical applications?

- Aluminum sheets are well-suited for pharmaceutical use, as they possess a range of advantageous properties. Firstly, their lightweight nature and exceptional resistance to corrosion make them an ideal choice for packaging pharmaceutical products. By shielding the contents from external factors like moisture, light, and oxygen, which could potentially compromise the medication's quality, aluminum sheets offer excellent protection. Additionally, aluminum sheets are highly malleable and can easily be molded into different shapes and sizes, allowing for customized packaging designs. Moreover, their availability in various thicknesses provides options for different types of pharmaceutical products, including tablets, capsules, and liquid medications. Furthermore, aluminum sheets boast a remarkable barrier property that effectively prevents the transfer of odors, flavors, and contaminants. This barrier ensures the integrity and safety of the medication throughout its entire shelf life. Furthermore, aluminum is a non-toxic material, guaranteeing that it does not react with drugs or alter their composition. This quality makes it an optimal choice for pharmaceutical applications, where maintaining the purity and stability of the medication is of utmost importance. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications, thanks to their lightweight nature, corrosion resistance, barrier properties, and non-toxic composition. By efficiently safeguarding and preserving pharmaceutical products, they ensure the quality and safety of these crucial medications.

- Q:Can the aluminum sheets be used for manufacturing aircraft engine components?

- Indeed, the utilization of aluminum sheets is possible for the production of aircraft engine components. Due to its exceptional strength-to-weight ratio and resistance to corrosion, aluminum is extensively employed within the aerospace sector. Despite being lightweight, it possesses the necessary strength to endure the strains and elevated temperatures inherent in aircraft engines. Furthermore, aluminum sheets can be effortlessly fashioned, rendering them apt for the creation of intricate engine components. Taken together, the favorable mechanical properties and applicability to aerospace scenarios make aluminum sheets the preferred option for manufacturing aircraft engine components.

- Q:which kind of abraser should be used for deburring of aluminum sheet?

- as for the polishing of aluminum material, we usually nylon wheel and similar products.

- Q:Can aluminum sheets be used for railway carriages?

- Yes, aluminum sheets can be used for railway carriages. Aluminum is a lightweight and durable material that offers numerous advantages, such as corrosion resistance, energy efficiency, and ease of fabrication. It has been increasingly utilized in the construction of railway carriages due to its strength-to-weight ratio, which allows for improved fuel efficiency and higher payload capacity.

- Q:Can the aluminum sheets be used for manufacturing chemical reactors?

- Yes, aluminum sheets can be used for manufacturing chemical reactors. Aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it suitable for various industrial applications, including the manufacturing of chemical reactors. Additionally, aluminum is lightweight and easy to shape, allowing for the construction of reactors with different sizes and designs. However, it is important to note that the choice of materials for chemical reactors depends on the specific requirements of the process and the chemicals involved. Certain corrosive or high-temperature environments may require the use of more specialized materials.

- Q:hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- You can never ever connect an Aluminum wire to a Copper wire. Never, copper in contact with aluminum and a bit of moisture acts like a Battery. Remember the old Grade School experiment where students made a battery using copper pennies and aluminum foil by simply contacting the foil to several pennies, then lighting a neon bulb! So copper in contact with aluminum creates a galvanic action due to potential difference and thus can cause a hot spot and a fire can literally break out in the junction box where you made the connection. Keep this always in mind since you have a whole house of that aluminum wire. To connect aluminum wire to a fixture you need a fixture that will accept an aluminum wire. Check that with the hardware or where or Lowes or wherever you buy the fixture from. There are fixtues with contacts points for wire in them that accept both copper and aluminum wire. So you do not need to replace the wire just to install the fixture. Or you can go to Lowes and get a special connector that safely connects the aluminum wire to a short piece of copper wire and then connect that copper pigtail piece to any fixture you buy. The danger of aluminum wire has never been that becomes brittle, but that corrosion forms at screw joints in the switches, outlet boxes and the like, that causing a resistance and that resistance acting literally like a heater and becoming red hot and starting a fire.

- Q:What are the different methods of joining aluminum sheet?

- Some of the different methods of joining aluminum sheet include welding, adhesive bonding, riveting, clinching, and mechanical fastening.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plain Aluminium Sheets for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords