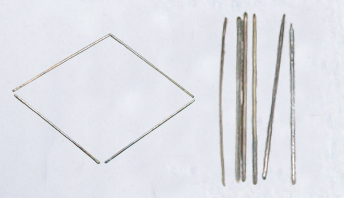

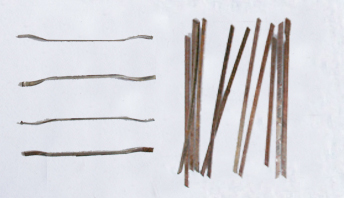

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Fiber Grade:

The grades of steel fiber should be suitably selected based on the temperature and atmosphere.

Physical, Mechanical and corrosion resistant properties of stainless steel fiber

| 304 | 310 | 330 | 446 | 430 |

Melting Point Range ℃ | 1400-1425 | 1400-1450 | 1400-1425 | 1425-1510 | 1425-1510 |

Elastic modulus at 870℃ | 12.66 | 12.66 | 13.71 | 9.84 | 8.44 |

Tensile strength at 870℃ | 127 | 155 | 197 | 54 | 48 |

Thermal expansion coefficient at | 20.16 | 18.58 | 17.64 | 13.14 | 13.68 |

Heat conductance at 500℃ | 21.5 | 18.7 | 21.6 | 24.4 | 26.3 |

Specific gravity at romm temperature, g/cm³ | 8.0 | 8.0 | 8.0 | 7.5 | 7.8 |

Loss of weight (%) after 1000 hours of circulating oxidization at 982℃(%) | 70(100h) | 13 | 18 | 4 | 70(100h) |

*Violent circulating state in air | 870 | 1035 | 1035 | 1175 | 870 |

982 | 1050 | 1150 | 1095 | 815 | |

Corrosion in H2S,Mil/yr | 200 | 100 | / | 100 | 200 |

Recommended max operating temperature when it is used in SO2℃ | 800 | 1050 | / | 1025 | 800 |

Corrosion in natural gas at 815℃ |

| 3 |

| 4 | 12 |

Corrosion in coking coal gas at 982℃ | 225 | 25 | 75 | 14 | 236 |

Nitrogenization in anhydrous ammonia at 525℃ | 80 | 55 | 20 | 175 | <304# |

Corrosion by CH2 at 454℃, Mil/yr | 4.8 | 2.3 |

| 8.7 | 21.9 |

Carbon pick-up of alloy % with solids carbonized at 982℃ for 24 hours and 40 times of circulations, % | 1.40 | 0.02 | 0.08 | 0.07 | 1.03 |

- Q:Can stainless steel wire be used for wire rope tensioners?

- Yes, stainless steel wire can be used for wire rope tensioners. Stainless steel is known for its high strength and corrosion resistance, making it suitable for various applications, including tensioning wire ropes.

- Q:Can stainless steel wire brushes be used for cleaning bathroom fixtures?

- Yes, stainless steel wire brushes can be used for cleaning bathroom fixtures. The stiff bristles of the brush are effective in removing tough stains and grime from surfaces such as faucets, showerheads, and other metal fixtures commonly found in bathrooms. However, it is important to use caution and apply gentle pressure to avoid scratching or damaging the fixtures.

- Q:How does the diameter of stainless steel wire affect its strength?

- The diameter of stainless steel wire directly affects its strength. Generally, a larger diameter wire will have greater strength compared to a smaller diameter wire of the same material. This is because a larger diameter wire has a larger cross-sectional area, resulting in a higher amount of material to resist forces and deformation. Consequently, the larger diameter wire can withstand more tension or load before breaking or undergoing permanent deformation.

- Q:Can stainless steel wire be used in high-temperature environments?

- Yes, stainless steel wire can be used in high-temperature environments. Stainless steel is known for its exceptional heat resistance, making it suitable for applications that involve exposure to high temperatures. The specific type of stainless steel used in wire manufacturing can determine the maximum temperature it can withstand. Austenitic stainless steels, for example, have excellent high-temperature properties and can withstand temperatures up to 870°C (1600°F). Other stainless steel alloys, such as 310 and 330, can withstand even higher temperatures. Therefore, stainless steel wire is a reliable choice for various high-temperature applications, including furnace components, heat exchangers, and exhaust systems.

- Q:Which is better, grade 12.9 screw and stainless steel screw?

- Stainless steel is usually divided into matrix tissue:1 ferritic stainless steel. Chromium 12% ~ 30%. Its corrosion resistance, toughness and weldability increase with the increase of chromium content, and the resistance to chloride stress corrosion is better than other kinds of stainless steel.2 austenitic stainless steel. Chromium more than 18%, but also contains about 8% of nickel and a small amount of molybdenum, titanium, nitrogen and other elements. Good comprehensive performance, corrosion resistant variety of media.3 austenite ferrite duplex stainless steel. It has the advantage of austenite and ferritic stainless steel and has superplasticity.4 martensitic stainless steel. High strength, but poor plasticity and weldability.5 、 precipitation hardening stainless steel. With excellent formability and good weldability, it can be used as an ultra high strength material in the nuclear industry, aviation and aerospace industry.

- Q:What kind of material does stainless steel screw thread and stainless steel cold heading wire generally use?

- Stainless steel screw thread and stainless steel cold heading wire, generally use 304M, 304HC, 316, three kinds of materials, is the 300 series of austenitic stainless steel is one of the most widely used materials. Each material obviously difference is: after cold processing, the material magnetism is 316<304HC<304M. 316, the material is resistant to chemical corrosion, corrosion resistance and sea water corrosion resistance, relative to 304M and 304HC to fine.

- Q:Is stainless steel wire resistant to rust?

- Yes, stainless steel wire is highly resistant to rust. This is due to the composition of stainless steel, which contains a minimum of 10.5% chromium. The chromium forms a protective layer on the surface of the wire, known as a passive layer, that prevents oxygen from reacting with the iron in the steel. This passive layer acts as a barrier against corrosion, making stainless steel wire highly resistant to rust and providing excellent durability and longevity in various environments.

- Q:Can stainless steel wire be used for making springs?

- Yes, stainless steel wire can be used for making springs. Stainless steel is a popular choice for spring manufacturing due to its excellent corrosion resistance, high tensile strength, and good elasticity. These properties make stainless steel springs suitable for a wide range of applications, including automotive, aerospace, medical devices, and industrial equipment. Additionally, stainless steel springs are known for their durability and longevity, making them a reliable choice for various spring applications.

- Q:Can stainless steel wire be used for wire rope sleeves?

- Yes, stainless steel wire can be used for wire rope sleeves. Stainless steel is known for its excellent corrosion resistance and high strength, making it a suitable material for various applications, including wire rope sleeves. Stainless steel wire rope sleeves are commonly used to create a secure and strong connection between wire rope and other components. They provide protection and support to the wire rope, preventing wear and damage. Additionally, stainless steel wire rope sleeves offer durability and longevity, making them an ideal choice for various industries, such as marine, construction, and transportation.

- Q:What are the common uses of stainless steel wire in the agricultural industry?

- Stainless steel wire finds numerous applications in the agricultural industry due to its unique properties and durability. One common use of stainless steel wire is for fencing purposes. It is widely used to create strong and reliable fences to enclose livestock and protect agricultural fields from external threats such as predators or unwanted intrusions. Stainless steel wire fences are highly resistant to corrosion, rust, and weathering, making them ideal for long-term use in outdoor environments. Another common use of stainless steel wire in agriculture is for trellising and supporting plants. The wire is often used to create structures like trellises, arbors, or support frames for climbing plants, such as grapes, tomatoes, or cucumbers. The high strength of stainless steel wire ensures that the plants are securely held in place, allowing them to grow vertically and maximize their exposure to sunlight. Stainless steel wire is also employed in the construction of agricultural equipment and machinery. It is used in the manufacturing of components such as springs, cables, hooks, and fasteners, where its strength and resistance to corrosion are crucial. Agricultural machinery, such as tractors, harvesters, or irrigation systems, often requires stainless steel wire to withstand the harsh conditions of outdoor use and exposure to moisture or chemicals commonly found in the farming environment. Additionally, stainless steel wire is used in animal husbandry for various purposes. It can be utilized in the production of cages, enclosures, or partitions to house animals safely and securely. Stainless steel wire is an excellent choice for these applications since it is resistant to chewing and scratching, ensuring the animals are contained and protected. In summary, stainless steel wire is utilized extensively in the agricultural industry for fencing, trellising, supporting plants, manufacturing agricultural equipment, and animal husbandry. Its unique properties of strength, durability, and resistance to corrosion make it an ideal material for various agricultural applications, contributing to the efficiency and productivity of farming operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords