Composite Composite Dimple Geomembrane for Highway Road Railway Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

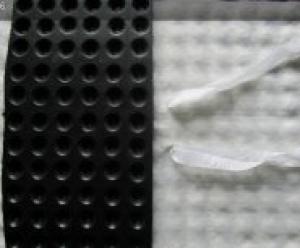

Composite Dimple Geomembrane for Highway Road Railway Building Material

It is a kind of geomembrane with dimples on the surface. The dimples can be in cylinder and semi cone shape. It could also be coated by non woven geotextile. The liquid and gas can go through freely between dimples.

Specification of Composite Dimple Geomembrane for highway road railway building material

Sheet material could be EVA or PE etc., thickness from 0.8mm t0 2. Omm, dimple height:

8mm, 15mm and 20mm, width from 2m t0 3m, composite layer is non woven geotextile, length could be made according to client' s request.

Property of Composite Dimple Geomembrane for highway road railway building material

I. Waterproofing and drainage: Form a channel, which water and gas can go through

2. Sound insulation and vibration isolation

3. Chemical resistance, resist to plants ' root

4. Easy for construction

5. Long lifetime

Application of Composite Dimple Geomembrane for highway road railway building material

I. Highway and railway waterproofing system

2. Underground waterproofing

3. Roof garden waterproofing projects

Production standard Composite Dimple Geomembrane for Highway Road Railway Building Material:

GB 18173.1-2012

- Q:How many grams of geotextiles on the top of the garage

- We would like to consult a professional company.

- Q:SNG400-3.5 geotextile is what model

- SNG400-3.5 refers to the national standard polyester staple acupuncture non-woven geotextile 400g / ㎡, width 3.5m. The index code for staple acupuncture nonwoven geotextiles is generally SNG / (1) (2) / (3) - (4) / (5). (1) that the use of raw materials fiber code: PET-polyester, PP-polypropylene, PA-nylon, PV-vinylon, PE-Ethylene (conventional polyester are generally vacant omitted code) (2) that polyester staple fiber non-woven Geotextile per unit area weight. (3) that the composite products in the polyester staple fiber non-woven geotextile weight per unit area, non-composite product vacancies. (4) width, expressed in meters (5) production department number: can express the product more specific characteristics, functions, varieties, sequences, etc., the general vacancy. For example, a 3.5m wide 400g / ㎡ polyester staple fiber nonwoven geotextile representation can be SNG / PET400-3.5, can also be expressed as SNG400-3.5

- Q:After the laying of drainage board and then need to lay a layer of geotextile it?

- After the laying of drainage board and then need to lay a layer of geotextile it?

- Q:What are the different geotextile installation guidelines?

- The different geotextile installation guidelines include proper site preparation, ensuring the soil is smooth and free of debris, anchoring the geotextile securely to prevent movement, overlapping the geotextile to ensure complete coverage, and using appropriate techniques for joining and sealing the geotextile. Additionally, it is crucial to follow manufacturer instructions and consult with an engineer for specific project requirements.

- Q:What are the considerations for geotextile selection in shoreline erosion control?

- There are several key considerations for geotextile selection in shoreline erosion control. First, the geotextile must have a high tensile strength to withstand the forces exerted by waves and currents. It should also be permeable to allow for water drainage and prevent the buildup of hydrostatic pressure. Additionally, the geotextile should be resistant to UV degradation and chemical exposure to ensure long-term durability. The choice of material and installation method should also take into account the specific site conditions, such as wave energy, sediment composition, and slope stability. Finally, cost and availability of the geotextile should be considered to ensure the solution is practical and feasible.

- Q:How do geotextiles contribute to the stability of road embankments?

- Geotextiles contribute to the stability of road embankments by providing reinforcement and separation. They act as a barrier between the different layers of soil, preventing their intermixing and maintaining their individual integrity. This enhances the load-bearing capacity of the embankment, reducing settlement and improving its overall stability. Geotextiles also help in drainage by allowing water to pass through, preventing excess moisture buildup that can weaken the embankment.

- Q:Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q:How do geotextiles improve the performance of railway tracks?

- Geotextiles improve the performance of railway tracks by providing a stable and durable foundation. They act as a barrier between the subgrade and the ballast, preventing the mixing of materials and reducing the risk of track settlement. Geotextiles also enhance drainage, preventing water accumulation and maintaining track stability. Additionally, they distribute load more evenly, reducing the pressure on the subgrade and minimizing the risk of track deformations. Overall, geotextiles enhance the longevity, safety, and performance of railway tracks.

- Q:What is the waterproof selection of artificial lake? How to build?

- There are many features ah

- Q:Can geotextiles be used in green wall systems?

- Yes, geotextiles can be used in green wall systems. Geotextiles are often used as a filtration and separation layer between the soil and the retaining structure in green walls. They help retain moisture, prevent soil erosion, and provide stability to the system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composite Composite Dimple Geomembrane for Highway Road Railway Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords