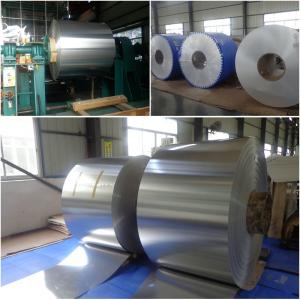

Mill finish aluminum coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy | AA1100, AA3003, AA3005, AA3105, AA8011 |

Temper | H16-18, H46 |

Thickness | 0.15mm – 1.0mm |

Width | 900mm – 1600mm |

Length | 200m – 2000m |

Chemical Composition (WT %)

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others | Rem. Al |

AA1100 | 0.116 | 0.478 | 0.069 | / | / | / | / | / | / | / | 99.70 |

AA3003 H16-18 | 0.59 | 0.66 | 0.01 | 0.32 | 0.21 | Tr | Tr | Tr | 0.02 | Tr | 98.15 |

AA3003 H46 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | / | / | / | 0.10 | / | 0.20 | 97.02 |

AA3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.10 | / | 0.25 | 0.10 | 0.20 | 96.10 |

AA3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.20 | / | 0.40 | 0.10 | 0.20 | 96.45 |

AA8011 | 0.5-0.9 | 0.6-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | / | 0.10 | 0.08 | 0.20 | 97.72 |

Mechanical Properties

| 0.2% Proof stress (Kg/Sqmm) | Ultimate tensile strength (MPa) | % Elongation | Bend test (180 Degree) | % Earing | Depth height (mm) |

AA1100 H16-18 | NA | 150-180 | 2.00 | NA | NA | NA |

AA3003 H16-18 | NA | 178.4 | 3.00 | NA | NA | NA |

AA3003 H46 | 165-205 | >145 | ≥1 | NA | NA | NA |

AA3005 H46 | NA | 195-250 | >180 | > 2 | NA | NA |

AA3105 H46 | 175-225 | >145 | ≥1 | NA | NA | NA |

AA8011 H16-18 | NA | 145-180 | 1.00 | NA | NA | NA |

Embossed color coatedaluminum coil

the company can produce the aluminum coil pattern are: classic orange peel pattern,and variation orange peel pattern (also called as bugs’ pattern). Thicknessspecification is 0.2mm ~ 0.6mm, width less than 1600mm. The materials used arefluorocarbon coated aluminum, polyester coated aluminum coil, aluminum roll,light aluminum, brushed aluminum rolls.

By embossing the surface of aluminum coil elegant, streamlined good, solidsense. Embossed aluminum coil aluminum coil can not only increase the thicknessof the aluminum coil thickness of 0.1 ~ 0.25mm. At the same time can enhance thestrength of aluminum coil, stiffness, and does not affect the original surfacelayer of the aluminum coil with the performance.

Embossed aluminum coil, wide range of uses. Mainly used for indoor and outdoordecoration, freezer, refrigerator, decorative aluminum products, bags, centralair conditioning and ventilation nozzles, and mechanical equipment enclosuresand so on. Is a new decorative material.

Thecompany has two production lines embossed aluminum coil: one for the simpleformula: put through Unwinder mechanical embossing roll winder windingembossed, convenient and quick. Another is the compound: that is embosseddirectly into the device placed in the coating line, coating and embossingsynchronization, when the coating needs of embossed aluminum coil, through thehydraulic transmission, the embossing machine, under the pressure rollerengagement, aluminum coating line directly in the embossing roll, fast, lowcost, no turnover.

Thickness range

0.2mm—0.6mm

Width range

800mm—1590mm

Technical parameters

Aluminum thickness | Coating thickness | MEK | T-bend | Impact | Adhesion | Pencil hardness | Boiling water proof |

0.20-0.60mm | ≥18±1um | ≥100times | ≤3T | 50kg.cm | 0grade | ≥HB | no change within 2 hours |

Performance and Application

Embossed aluminum coil for roofing is coatedwith high-performance polyester paints. And its each performance index is up toor exceeds the national standard. With its glorious colors, little chromatism,strong impact and easy machinability, the product serves as a premium materialin roofing, electric appliances, etc.

- Q:Can aluminum coils be used in the production of window frames?

- Yes, aluminum coils can be used in the production of window frames. Aluminum is a lightweight and durable material that is commonly used in the construction industry due to its corrosion resistance and strength. Aluminum coils can be easily formed into various shapes, including window frames, making them an ideal choice for window manufacturing. Additionally, aluminum is a sustainable material that can be easily recycled, making it an environmentally friendly option for window frame production.

- Q:How are aluminum coils used in HVAC systems?

- Aluminum coils are used in HVAC systems for their efficient heat transfer capabilities. They are typically used in air conditioning units and heat pumps to cool or heat the air that circulates through the system. The coils play a crucial role in the refrigeration cycle by absorbing heat from the indoor air and releasing it outside. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for these coils, ensuring efficient and reliable performance in HVAC systems.

- Q:How are aluminum coils protected against mechanical damage?

- Aluminum coils are protected against mechanical damage through various methods such as applying protective coatings, using durable outer casings, employing edge guards, and ensuring proper handling during transportation and installation.

- Q:Classification of aluminium rolls for aluminium rolls

- To spare, so in order to cope with the development of science and technology, in order to contain other aluminum alloy elements, the International Federation of special aluminum strip showed that 9000 series of alternate series, waiting for a new product to fill the gaps of the 9000 series.

- Q:Aluminum is a transition metal, woudn't the stock naming system apply to this formula?

- Aluminium has only one oxidation state i.e +3. Hence it does not matter whether we call it aluminium (iii) oxide or simply aluminium oxide. However copmare iron oxide. Here it could be FeO or Fe2O3 so we have to distinguish by indicating Iron (II) Oxide for FeO and Iron (III) oxide for Fe2O3.

- Q:Are aluminum coils suitable for high-pressure applications?

- No, aluminum coils are not suitable for high-pressure applications.

- Q:How do aluminum coils perform in extreme temperatures?

- Aluminum coils are known for their excellent performance in extreme temperatures. They have a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making them highly resistant to heat. Additionally, aluminum has a low coefficient of thermal expansion, which means it can withstand rapid changes in temperature without warping or cracking. This makes aluminum coils a reliable choice for applications in both high and low-temperature environments.

- Q:If this is true then how do I take my aluminums temperature without fear of breaking the themometer and get mercury all over it?

- hang on ill have a psychic moment... ok, we have two types of metal. ferrous and non ferrous... ferrous rusts... Fe... iron. non ferrous... no iron... Copper and aluminium, and zinc and silver appear int he periodic table, they are NOBLE metals.. pure elements... copper corrodes in acid aluminium corrodes iin alkali and i dont know what corrodes Zinc... and theyre digging up pieces of silver and gold which are thousands of years old, out of the sea... and they look as good as the day they were made... oh, and raw untreated steel starts rusting within hours of exposure to water and air... without air, the metal willstill corrode, but it'll take much much longer... your average ford starts rusting itself to death within 10 years... yet the titanic has been under the ocean for almost 100 years... and ok, i know the titanic hull is a bit thicker than a ford wheel arch... but the principle holds.

- Q:What are the fire resistance properties of aluminum coils?

- Due to its unique characteristics, aluminum coils possess excellent fire resistance properties. This is primarily attributed to the metal's high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), enabling it to endure high temperatures without deforming or melting. Moreover, when exposed to air, aluminum forms a thin layer of oxide on its surface. This oxide layer acts as a protective barrier against fire and prevents further oxidation. It is worth noting that this oxide layer possesses a high melting point and is non-combustible, making it an effective fire retardant. Another advantage of aluminum is its poor heat conductivity. Consequently, it does not readily transfer heat during a fire, thus slowing down the spread of flames. As a result, aluminum coils are extensively utilized in various applications where fire resistance is a vital requirement, such as building construction, transportation, and electrical wiring.

- Q:Aluminum coil area, with aluminum sheet area, how is not the same?

- Direct measurement length and width calculation area of aluminium plate;The aluminum coil can measure the volume of the aluminum coil and then calculate the area by dividing the thickness. You can also measure the mean diameter, calculate the perimeter, multiply the number of laps, the width, and calculate the area.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill finish aluminum coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords