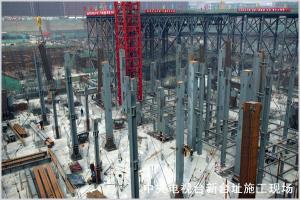

Wuyang 1E1839 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TMCPhigh-strengthsteel(non-tempered):E500.Q500E.S500M.

1.SA516Gr70. SA516Gr65.S355series.P355series.Q345Rseries.AH32-36.DH32-36.EH32-36.Intensitylevel isQ345Eclass.P460.S460 (-20 ℃impact)seriesQ460Dclasses.

2containers.Ship plate steeland other specialsteels,at the sameintensity levelbase priceplus500 yuan/ ton.

1: AsolutionHICSteel(HIC-A)toBsolutionHICsteel(HIC)basisplus300 yuan/ton.

2: R-HICHICsteeltosteelAsolution(HIC)basisplus500 yuan/ ton.

3: TypeII HICsteel100 yuan/ton, IIItypeHICsteelplus400 yuan/ ton.

4:For theHICsteelQ345R SA516Gr70 SA516Gr65correspondingclassQ345RQ245RQ245R SA516Gr60correspondingclass..

6, nuclearHRsteelcontainersincludeda quality plan,the completion ofthe report,all the requirements forsimulationafter weldingand so on.

- Q:What is the weight of a standard steel sheet?

- The weight of a standard steel sheet can vary depending on its thickness and dimensions. However, a commonly used gauge for steel sheets is 22 gauge, which has an approximate weight of 1.25 pounds per square foot.

- Q:What are the driving methods for steel sheet piles?

- The construction of steel sheet pile mainly consists of mechanical hand, crawler crane, vibratory hammer and static pile driving machine.

- Q:Are steel sheets suitable for electrical transformer cores?

- Steel sheets are an appropriate choice for electrical transformer cores. They are widely utilized in transformer cores because of their magnetic characteristics and their ability to effectively conduct magnetic flux. The steel sheets used in transformer cores are typically made from top-quality electrical steel, also known as silicon steel or transformer steel. This specific type of steel demonstrates low core losses and high magnetic permeability, which make it an optimal selection for transformer applications. The structure of the steel sheets, which is made up of laminations, aids in reducing eddy current losses by establishing a path of high electrical resistance. These sheets are also coated with an insulating varnish to further minimize eddy current losses and prevent electrical short circuits. The laminations are then assembled together to form the core, creating a path of low reluctance for the magnetic field generated by the transformer's primary winding. The incorporation of steel sheets in transformer cores ensures efficient energy transfer by minimizing energy losses. The magnetic properties of steel contribute to the transformation and regulation of electrical power, allowing transformers to increase or decrease voltage levels while maintaining high efficiency. Moreover, steel sheets possess exceptional mechanical strength and stability, which guarantees the long-term durability of transformer cores. In conclusion, steel sheets are highly suitable for electrical transformer cores due to their magnetic properties, low core losses, high magnetic permeability, and mechanical strength. These properties facilitate efficient energy transfer, voltage regulation, and long-term reliability in transformer applications.

- Q:How do steel sheets perform in corrosive environments like saltwater?

- Steel sheets exhibit excellent resistance to rust and corrosion in corrosive environments like saltwater. This is primarily due to the presence of chromium in the steel, which forms a protective layer of chromium oxide on the metal surface. This layer acts as a barrier, preventing direct contact between the steel and the corrosive elements in saltwater, thereby reducing the risk of corrosion. However, it is important to acknowledge that steel sheets are not completely immune to saltwater corrosion. Extended exposure to saltwater can still lead to some degree of corrosion, particularly when combined with other factors such as high temperatures, abrasion, or impurities in the water. To enhance the performance of steel sheets in saltwater environments, various protective coatings can be utilized. These coatings, including paint, galvanization, or epoxy, provide an extra layer of protection to the steel, further minimizing the chances of corrosion. Regular maintenance and inspection are vital to ensure the long-term effectiveness of steel sheets in saltwater environments. This involves cleaning the surface, eliminating any accumulated salt or debris, and rectifying any damaged or compromised areas of the protective coating. Overall, although steel sheets possess good resistance to corrosion in saltwater environments, it is imperative to take appropriate precautions such as using protective coatings and conducting regular maintenance to ensure their optimal performance and durability.

- Q:Are steel sheets suitable for construction scaffolding?

- Yes, steel sheets are suitable for construction scaffolding. Steel is a strong and durable material that can provide the necessary support and stability required for scaffolding systems. It can withstand heavy loads and provide a secure platform for workers to perform their tasks safely. Additionally, steel sheets can be easily assembled, disassembled, and reused, making them a cost-effective choice for construction scaffolding.

- Q:Are the steel sheets resistant to staining or discoloration?

- Indeed, staining or discoloration poses no challenge for steel sheets. Renowned for their durability and impermeable surface, steel exhibits resistance against the infiltration of liquids or chemicals that may induce staining. Enhancing this resistance, steel sheets are frequently coated with protective finishes or treatments. These coatings function as a shield, effectively hindering any potential staining substances from permeating the steel's surface. Consequently, steel sheets stand as an exceptional option for scenarios that prioritize resistance to staining or discoloration, such as kitchen appliances, automotive components, or outdoor structures.

- Q:Can steel sheets be used for clamps or fasteners?

- Steel sheets alone cannot function as clamps or fasteners; nonetheless, they possess the potential to be transformed into such components. By cutting, shaping, and manipulating steel sheets, one can manufacture a range of clamps and fasteners, including brackets, plates, or strips. These manufactured components offer strength, durability, and secure attachment, making them suitable for various applications. Hence, while steel sheets in their original form cannot serve as clamps or fasteners, they can be utilized to create the necessary components for these purposes.

- Q:How to choose welding method for welding different plate and thick steel plate?

- Plate groove, the groove thickness is less than or equal to the thickness of the sheet, the welding arc to a plate, the molten pool of molten iron melt sheet, the specific point of view of plate thickness difference, observe the molten pool adjust current, prevent sheet welding, double-sided welding when necessary.

- Q:Can steel sheets be painted?

- Yes, steel sheets can be painted.

- Q:Are the steel sheets easy to maintain?

- Steel sheets are typically easy to maintain, as they possess durability and corrosion resistance, thus necessitating minimal upkeep. A simple cleaning using mild detergent and water usually suffices to keep them looking pristine and shiny. Moreover, steel sheets eliminate the need for painting or staining, further diminishing maintenance demands. In situations involving scratches or minor damages, repairs or buffing can be effortlessly executed. All in all, steel sheets are an excellent choice for diverse applications, requiring little maintenance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wuyang 1E1839 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords