ALUMINIUM COIL PREPAINTED-1/3/5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Coil Prepainted Description

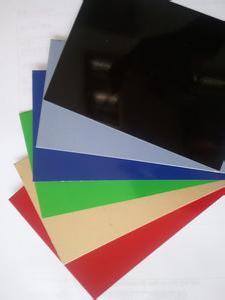

Prepainted aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The prepainted aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Coil Prepainted :

1) Perfect weather ability, high strength, no special maintenance

2) Convenient construction, short working time

3) Excellent machining heat insulation, sound insulation property and perfect fireproof performance

4) High plasticity, good impact resistance, quakeproof performance and reducing buildings load

5) Goods smoothness, lightweight and rigid, beautiful and cheap

6) Various colors available

7) Simple machining equipments, processing in spot.

Image of Aluminium Coated Coil:

Aluminium Coated Coil Specification:

Product Name | Aluminum Coil |

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of AA5052 Aluminium Coated Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:How do aluminum coils compare to other metal coils like steel or copper?

- Aluminum coils offer several advantages and disadvantages when compared to other metal coils like steel or copper. In terms of weight, aluminum coils are significantly lighter than steel coils. This makes them easier to handle and transport, which can reduce costs in the manufacturing and construction industries. On the other hand, steel coils are much stronger and more durable than aluminum, making them more suitable for heavy-duty applications where strength is crucial. In terms of corrosion resistance, aluminum coils have a natural oxide layer that protects them from rust and corrosion. This makes them an excellent choice for outdoor applications or environments with high humidity. Copper coils also have excellent corrosion resistance, but steel coils are more prone to rust and require additional protective coatings. Thermal conductivity is another factor to consider. Copper is known for its exceptional thermal conductivity, making it highly efficient for applications that require heat transfer, such as HVAC systems. Aluminum coils have lower thermal conductivity than copper, but they are still widely used in various heat transfer applications due to their lightweight and cost-effectiveness. Cost is a significant consideration when comparing different metal coils. Aluminum coils are generally more affordable than copper and steel coils, which makes them a popular choice for many industries. However, steel coils are often the most cost-effective option for heavy-duty applications due to their strength and durability. Overall, the choice between aluminum, steel, or copper coils depends on the specific requirements of the application. Each metal has its own unique properties and advantages, and selecting the right material involves considering factors such as weight, strength, corrosion resistance, thermal conductivity, and cost.

- Q:I heard that clay pots and aluminum cans are great caves for my fish to breed in but will the can rust???

- Aluminum will not rust. Only iron rusts. Because steel has iron in it, steel can rust.

- Q:What is the impact resistance of aluminum coils?

- The specific impact resistance of aluminum coils may vary depending on the alloy and temper of the aluminum. In general, aluminum is renowned for its excellent impact resistance due to its inherent strength and ductility. Aluminum coils find extensive use in industries like automotive, construction, and packaging, where they are likely to encounter impact or mechanical stress. Manufacturers frequently employ aluminum alloys like 3003, 5052, or 6061 for coil production. These alloys are recognized for their high tensile strength, which contributes to their impact resistance. Furthermore, aluminum possesses the capability to absorb and distribute energy upon impact, thereby reducing the likelihood of damage or deformation. It is important to note, however, that various other factors can influence the impact resistance of aluminum coils. These factors include coil thickness, surface finish, and the presence of additional protective coatings or treatments. Generally, thicker coils offer greater impact resistance, while coatings or treatments can enhance durability and resistance to impact. In conclusion, the impact resistance of aluminum coils can generally be considered satisfactory. However, it is advisable to consult with a manufacturer or supplier to ascertain the specific impact resistance properties of the chosen aluminum alloy and coil.

- Q:How do aluminum coils contribute to thermal management?

- The exceptional heat transfer capabilities of aluminum coils are crucial in thermal management. Aluminum possesses a high thermal conductivity, allowing it to efficiently transfer heat from one area to another. This quality plays a vital role in applications that require effective thermal management, including air conditioning systems, refrigeration units, and heat exchangers. In air conditioning systems, aluminum coils are commonly employed in the condenser and evaporator coils. The condenser coil releases heat from the refrigerant to the surrounding air, while the evaporator coil absorbs heat from the indoor air to cool it down. The high thermal conductivity of aluminum ensures efficient heat transfer between the refrigerant and the surrounding air, resulting in faster and more effective cooling. Similarly, refrigeration units utilize aluminum coils in the evaporator coils to extract heat from the interior space. The aluminum coils assist in removing heat from the refrigerated area and transferring it to the outside environment, maintaining a lower temperature inside the unit. Heat exchangers, which are utilized in various industries like automotive, power generation, and HVAC, also benefit from aluminum coils. Heat exchangers are devices that transfer heat between multiple fluids with different temperatures. Aluminum's high thermal conductivity enables efficient heat exchange between the fluids, enhancing overall system performance and energy efficiency. Furthermore, aluminum coils possess lightweight properties and are resistant to corrosion, making them durable and suitable for long-term use in harsh environments. These characteristics further contribute to effective thermal management by ensuring reliable heat transfer and reducing the risk of system failure or decreased efficiency. In conclusion, aluminum coils play a crucial role in thermal management systems by facilitating efficient heat transfer, expediting cooling or heating processes, and improving overall system performance. Their high thermal conductivity, lightweight nature, and corrosion resistance make them the preferred choice in various applications requiring effective thermal management.

- Q:What is the typical coefficient of friction for aluminum coils?

- The typical coefficient of friction for aluminum coils can vary depending on various factors such as the surface conditions, lubrication, and the specific type of aluminum alloy used. However, in general, the coefficient of friction for aluminum coils is relatively low compared to other materials. It typically falls within the range of 0.1 to 0.4.

- Q:Can aluminum coils be used for signage and display applications?

- Signage and display applications can utilize aluminum coils effectively. Aluminum, being a versatile and lightweight material, finds extensive usage in the signage industry. The ability to easily shape and resize aluminum coils makes them suitable for various signage and display purposes. When it comes to outdoor signs, such as billboards, building signs, and traffic signs, aluminum coils are commonly employed due to their exceptional resistance to weather and durability. They can endure harsh weather conditions like rain, snow, and UV exposure without undergoing rusting or fading. This quality makes them a reliable option for signage with long-lasting effects. Moreover, aluminum coils can be coated with various finishes like paint or powder coating to enhance their appearance and provide added protection against corrosion. This enables customization and branding opportunities, making aluminum coils appropriate for both functional and decorative signage. Regarding display applications, aluminum coils can be utilized to create exhibition stands, trade show displays, retail displays, and other promotional materials. Their lightweight nature facilitates easy transport, assembly, and disassembly, making them advantageous for portable displays. Additionally, aluminum coils can be easily printed on or laminated, enabling the incorporation of graphics and visuals to capture attention and convey messages effectively. All in all, aluminum coils are a versatile and resilient material suitable for a wide array of signage and display applications. Their ability to withstand weather, customizable finishes, and lightweight properties contribute to their popularity in the industry.

- Q:Are aluminum coils suitable for outdoor signage and displays?

- Indeed, outdoor signage and displays can indeed benefit from the use of aluminum coils. The reason for this is that aluminum is a material known for its exceptional durability and resistance to weather conditions, which makes it an ideal choice for outdoor applications. Its ability to withstand extreme temperature fluctuations, UV rays, moisture, and corrosion is well-known. Moreover, aluminum coils possess the advantage of being lightweight, yet still offering considerable strength, making them easy to handle and install. Furthermore, their versatility allows for easy shaping and forming into various sizes and designs. Additionally, aluminum boasts excellent printability, ensuring vibrant and long-lasting graphics. In summary, aluminum coils present a dependable and cost-effective solution for outdoor signage and displays.

- Q:Calculate the specific heat of aluminum (in calories).mass of aluminum25.0 gmass of water23.2ginitial temperature of aluminum98.0Cinitial temperature of water20.0Cfinal temperature of water33.0Cround to three decimal places, do not include units.

- Heat gained by water = heat lost by aluminum Heat = H mass = m specific heat =c change in temperature = dT H = mcdT mcdT for water = mcdT for Al (23.2)(1.00)(13) = (25.0)(c(Al))(33-98) c(Al) = (23.2)(1.00)(13)/(25.0)(65) = 0.186 This value is just a bit below the known value of specific heat for aluminum, where c = 0.217 cal/g.C

- Q:What are the different types of alloys used for aluminum coils?

- There are several different types of alloys that are commonly used for aluminum coils. The most commonly used alloy for aluminum coils is 3003. This alloy is known for its excellent corrosion resistance and moderate strength. It is often used in applications where high strength is not required, such as in roofing and siding. Another commonly used alloy for aluminum coils is 5052. This alloy has good weldability and formability, making it suitable for a wide range of applications. It is often used in the automotive industry for body panels and fuel tanks. 6061 is another popular alloy for aluminum coils. This alloy has excellent strength and is often used in structural applications. It is commonly used in the aerospace industry for aircraft parts and in the construction industry for structural components. Other alloys that are used for aluminum coils include 1100, 5005, and 8011. Each of these alloys has its own unique properties and characteristics, making them suitable for different applications. For example, 1100 is known for its high electrical conductivity and is often used in electrical applications, while 8011 is commonly used for packaging and food containers due to its excellent corrosion resistance. In summary, the different types of alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys offer a range of properties and characteristics that make them suitable for various applications across industries such as automotive, aerospace, construction, and packaging.

- Q:What are the energy efficiency benefits of aluminum coils?

- Aluminum coils offer several energy efficiency benefits. Firstly, aluminum is a highly conductive material, allowing for faster and more efficient heat transfer compared to other coil materials. This leads to improved cooling or heating performance, reducing energy consumption. Additionally, aluminum coils are lightweight, which means less energy is required to move them, resulting in energy savings during transportation and installation. Moreover, aluminum's corrosion resistance properties ensure the longevity of the coils, reducing the need for frequent replacements and minimizing overall energy consumption. Lastly, aluminum is a recyclable material, contributing to sustainability and reducing the energy-intensive process of manufacturing new coils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ALUMINIUM COIL PREPAINTED-1/3/5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords