HDPE Uniaxial Geogrid with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

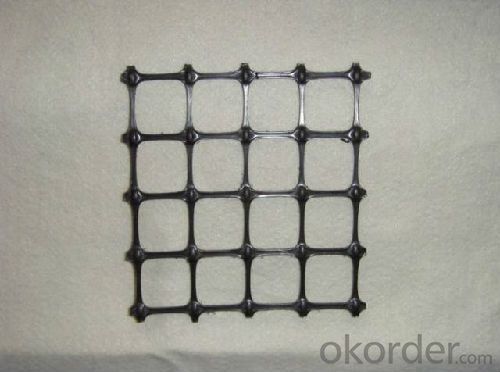

HDPE Uniaxial Geogrid Introduction

25-25KN,30-30KN,50-50KN,80-80KN,100-100KN,120-120KN,150-150KN,200-200KN

Width≤6m; Length 50m or as requested

HDPE Uniaxial Geogrid Features

1. In high tensile strength

2. Low elongation

3. Anti-erosion, anti-aging

4. Light weight, structural uniformity, easy for construction

5. Flame retardant, anti-static, good overall performance, easy for mechanized operation

6. Good affinity with base materials

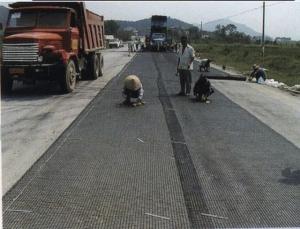

HDPE Uniaxial Geogrid Application

ation

1. Roadbed reinforcement in highway, railway and municipal road

2. Reinforcement and separation in dam and river, improving soft soil bearing capacity and stability

3. Roadbed slope reinforcement, retaining wall reinforcement

HDPE Uniaxial Geogrid Specification

Technical Data

Item | Specification and Index | ||||||

30-30 | 35-35 | 50-50 | 80-80 | 100-100 | 125-125 | 150-150 | |

Limit Tensile Strength (MD&TD)(KN/m) | ≥30 | ≥35 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

Elongation at nominal tensile strength (MD&TD)(%) | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤14 |

Tensile Strength@2% elongation(MD&TD)(KN/m) | ≥10 | ≥12 | ≥17 | ≥28 | ≥35 | ≥43 | ≥52 |

Tensile Strength@5% elongation(MD&TD)(KN/m) | ≥20 | ≥24 | ≥34 | ≥56 | ≥70 | ≥86 | ≥104 |

Production Standard : JT/T480-2002 | |||||||

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q:What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q:What are the advantages of using geogrids in flexible pavements?

- Geogrids offer several advantages when used in flexible pavements. Firstly, they enhance the strength and stability of the pavement structure by distributing the load over a wider area, reducing the potential for deformation and rutting. Secondly, geogrids improve the overall performance and durability of the pavement by preventing the lateral movement of aggregate particles, thereby reducing rutting, cracking, and surface irregularities. Additionally, these grids help in controlling reflective cracking, which can occur when there are underlying cracks in the pavement layers. Overall, the incorporation of geogrids in flexible pavements results in improved structural integrity, increased lifespan, and reduced maintenance requirements.

- Q:Are geogrids resistant to biological clogging?

- Yes, geogrids are resistant to biological clogging. They are typically made from materials such as high-density polyethylene (HDPE) or polyester which are resistant to biological degradation. Additionally, geogrids have an open structure that allows for effective drainage and prevents the accumulation of organic matter that could lead to clogging.

- Q:Can geogrids be used in foundation stabilization?

- Yes, geogrids can be used in foundation stabilization. They are commonly used in civil engineering and construction projects to reinforce soil and improve the stability of foundations. Geogrids are typically installed horizontally or vertically within the soil to distribute loads and prevent soil movement, thereby enhancing the overall stability and performance of foundations.

- Q:What are the factors affecting the durability of geogrids?

- The factors affecting the durability of geogrids include the material composition of the geogrid, the quality of the manufacturing process, exposure to UV radiation, chemical exposure, temperature fluctuations, installation techniques, and the level of stress or load placed on the geogrid.

- Q:Can geogrids be used in landfills?

- Yes, geogrids can be used in landfills. Geogrids are commonly used in landfill applications to reinforce slopes, stabilize soil, and improve overall stability and performance of the landfill structure.

- Q:What are the factors that affect the installation quality of geogrids?

- The factors that affect the installation quality of geogrids include the type and quality of the geogrid material, proper surface preparation, adequate compaction, appropriate tensioning and anchoring, proper overlap and seam construction, and adherence to manufacturer's guidelines and specifications. Additionally, factors such as weather conditions, soil type, and site-specific requirements can also impact the overall installation quality of geogrids.

- Q:What are the quality control measures for geogrid manufacturing?

- Some quality control measures for geogrid manufacturing include regular testing of raw materials, strict adherence to manufacturing processes and specifications, comprehensive inspection and testing of finished products, and continuous monitoring and improvement of production processes to ensure consistent quality and performance of the geogrids. Additionally, compliance with industry standards and certifications, such as ISO 9001, is often followed to ensure the highest quality standards are met.

- Q:What are the differences between geogrids and geonets?

- Geogrids and geonets are both geosynthetic materials used in civil engineering and construction, but they serve different purposes. Geogrids are typically used for soil reinforcement and stabilization, providing tensile strength to improve the stability of soil structures. On the other hand, geonets are primarily used for drainage applications, allowing the flow of water while retaining soil particles. In summary, geogrids enhance soil stability, while geonets aid in drainage.

- Q:The difference between steel plastic two-way geogrid and steel plastic geogrid

- One way steel plastic geogrid is longitudinal tension requirements, only the detection of longitudinal tension.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

HDPE Uniaxial Geogrid with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords