2018 China PPR Pipe Fittings of industrial application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: Plastic

Technics: injection

Place of Origin: China (Mainland)

Connection: Welding

Head Code: round

Color: white

Packaging Details: PE bag and carton

Delivery Detail: 30 Days

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

Why Us?

1.We can make any requirements in design, pattern, color and size.

2.We can make customer's logo on the surface of products.

3.The dimension tolerance of our products is controlled within 0.03mm.

4.Our products are child safety, pet safety and environment-friendly.

5.Our products are exported to America, Europe, India, west Asia, etc., and conforms to the standard test.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

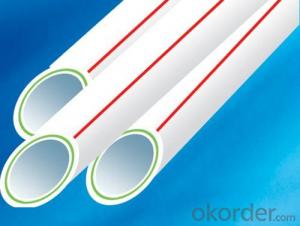

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q:Hello, I'm making my own skin hair care products and my question is, what store other than Micheals can I purchase plastic containers and tubes to put my product in? I'm not talking about food items either I'm talking about Jars to store shea cocoa butter in it. Also, I want to be able to provide my own wrapper? Like what can I do to make my own wrapper sticker ... basically advertising my own product line's name and whichever design I'd like on it?? Thanks in advance :)

- You can purchase standard plastic jars (10ml-500ml) from the UK specialist Manuplastics Ltd.

- Q:Can plastic tubes be used for storing agricultural chemicals?

- Yes, plastic tubes can be used for storing agricultural chemicals. Plastic tubes are commonly used for packaging and storing various chemicals, including agricultural chemicals such as fertilizers, pesticides, and herbicides. They are lightweight, durable, and resistant to corrosion, making them suitable for long-term storage and transportation of agricultural chemicals. Additionally, plastic tubes can be designed with various sizes and closures to ensure proper containment and minimize the risk of leakage or contamination.

- Q:Can plastic tubes be used for pharmaceutical packaging?

- Yes, plastic tubes can be used for pharmaceutical packaging. They are commonly used for packaging creams, ointments, gels, and other semi-solid products. Plastic tubes offer advantages such as easy dispensing, precise dosage control, and protection against contaminants.

- Q:What flange plate is used to connect the plastic pipe to the flange valve?

- The sleeve flange connection is to make the ends of the two connecting pipes make an edge of about 6~8, and the special flange is sheathed at the flanging position, and the gasket is screwed between the flanges to tighten the bolts. The plastic ring can also be welded at the end of the pipe to replace the flanging, and the plastic pipe needs uniform width and straight edge at the end of the flanging so as to ensure the tight interface. Material is more applicable.

- Q:How are plastic tubes tested for quality and safety?

- Plastic tubes are tested for quality and safety through various methods such as visual inspection, pressure testing, and material analysis. Visual inspection involves checking for any defects, imperfections, or inconsistencies in the tubes' appearance. Pressure testing is conducted to ensure the tubes can withstand the intended pressure without leaking or bursting. Material analysis involves examining the composition of the plastic to ensure it is safe and meets the required standards. These tests help ensure that the plastic tubes are of high quality and safe to use in their intended applications.

- Q:I'm so scared ):What should I be doinglooking out for?worst case scenario?HELP

- The plastic tubes could have gotten lodged in his intestines somewhere. Best thing you can do is take him to a vet.

- Q:Can duct tape be used to fix flexible plastic tubing? We sprung a leak in the flexible plastic tubing last night and so I am hoping I can just use duct tape to fix the small crack in the flexible plastic tubing. Thanks,Jeff

- Duct okorder ) online catalog there are a couple of better alternatives for you with tapes made specifically for flexible tubing. Hope that helps.

- Q:why doesnt the plastic top of superglue stick to the tube?

- It does eventually. Superglue has acetone in it, which is a solvent that's extremely volatile (evaporates very quickly). And, as long as the cap is properly sealed, the acetone won't evaporate for a while. So, the glue won't dry and glue the cap on. But, if the cap is open in the slightest - or simply over time - the acetone will start to dry up and the glue cures inside the cap. Then the only way to get it off is to use pliers to crush the hardened glue in the cap and then to twist the cap off. But, this usually ruins the cap and it will never seal properly again. At this point, it's better to just throw it away and get some more.

- Q:Can plastic tubes be used in high-pressure applications?

- Yes, plastic tubes can be used in high-pressure applications, but it depends on the specific type of plastic used and the pressure level required. Certain types of plastic, such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), and polypropylene (PP), have good resistance to pressure and can withstand high-pressure environments. However, it is important to consider factors like temperature, chemical compatibility, and the specific requirements of the application when selecting plastic tubes for high-pressure use.

- Q:i finally bought a new faucet, and changed it. it seems that there is no more leaking from the faucet.but now, it seems that there is some water leaking right under that white plastic screw. around the plastic looking tube. inside of it, there is a dark rubber kind of ring around it. i can't take out the white plastic screw (i don't know the those special names.) otherwise, i will just put some plastic tape, and seal it. that shouldn't be so hard. so my question is 1. what do you recommend? should i buy a new tube? or is there any other way to fix this thing?extra question.2. the new faucet has the top iron thing and a black plastic base. i put the plumb's putty on the edge of top and bottom of the black plastic base. i am thinking what if there are some water leaking inside of the faucet, if i sealed the whole plastic base, the water will accumulate inside of it. did i do the right thing at all?

- Looks like the plastic connector has a duff washer in it. It will keep weeping and its annoying. PTFE plastic tape may assist but to be fair id do this: Remove the tube and make sure the threaded brass tail of the tap is flat and smooth wioth no burrs. Second, make sure the threads on the tube arent frayed or have been cross threaded so it goes on slightly crooked. third, make sure the black rubber washer in the tube connector end isnt twisted, split or slipping inside the tail when tightened up fully (common with some makes) fourth, make sure you havent overtightened it, this can cause the above. fifth, where the white plastic braded tube meets the shiny metal crimp section (before the white plasic) it can sometimes fail. Manufaturing fault but not uncommon. Done worry about your question 2. Its 99% question 1. Plumbing and heating engineer for 12 years - a little tip - if you have to force it, your probably doing it wrong. Its a good motto for plumbing.... and in life!!! Yeah baby! Good luck

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2018 China PPR Pipe Fittings of industrial application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords