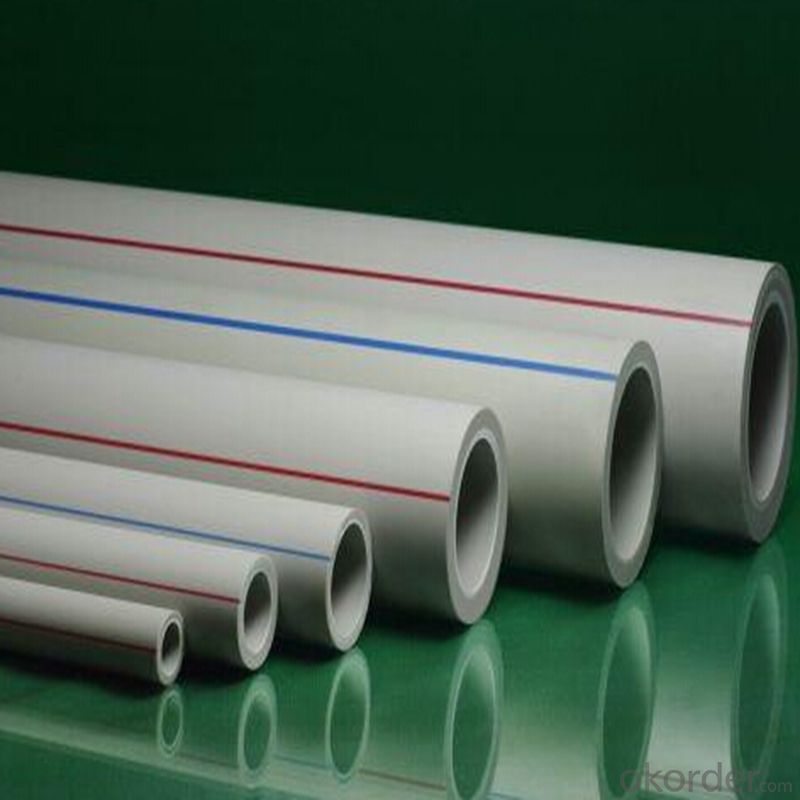

PPR Pipes and Fittings with Manufacturer Professional Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R pipes are made of Polypropylene Random ,which has comprehensive physical and chemical property ,as well as Hygiene property.

With the high-quality materials .Minde PP-R pipes meet the DIN8077/8078 standard .Depending on the pressure ,the pipes can be used in temperature up to 70°Cwith an extrapolated service life up to 50 years .

Product Applications

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioner

Why Us?

1.We can make any requirements in design, pattern, color and size.

2.We can make customer's logo on the surface of products.

3.The dimension tolerance of our products is controlled within 0.03mm.

4.Our products are child safety, pet safety and environment-friendly.

5.Our products are exported to America, Europe, India, west Asia, etc., and conforms to the standard test.

Product Specification

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

Main Product Features

1)Pressure Rating: 1.0Mpa,1.25MPa, 1.6MPa, 2.0MPa ,2.5MPa

2)Colors: Green, White, Grey, Red, Blue, Yellow and other color on request

3)Certification: ISO9001, ISO14001,CE, ROHS, SGS and so on

4)Standard: DIN8077/8078

5)Applications: Cold or hot water supply

FAQ

· Q1: How Can I Get A Sample?

· A1: You can get samples by communicate with our export sales.

· Q2: How Long Is Delivery?

· A2: Delivery time will be30-45days according to order quantity.

· Q3: What Is The MOQ?

· A3: MOQ depends on different items.

· Q4:What Is Our Normal Payments Terms?

· A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q:Can plastic tubes be used for outdoor applications?

- Yes, plastic tubes can be used for outdoor applications.

- Q:What are the physical properties of acrylic tubes (18width, 24diameter)? What is the property difference between a tube that is extruded compared to casted? All I'm really asking is which one is stronger and how strong is it? Is it easy to drill holes in them? Is PVC stronger, and what are the properties of that?

- Cast Acrylic Tubes are used in many applications in place of extruded or molded acrylic because of better machining properties, greater clarity, better resistance to heat distortion and higher tensile strength. In short: yes, cast is stronger than extruded yes, it is easy to drill holes, just take it slow It is not cut and dry which one is stronger, they are actually quite similar in certain properties such as tensile strength, flexural strength, and compressive strength. I would recommend getting a small piece of each and trying them out in your application. Just so you know, PVC is going to be cheaper than Cast acrylic at these sizes.

- Q:What are the advantages of using plastic tubes in the medical industry?

- There are several advantages of using plastic tubes in the medical industry. Firstly, plastic tubes are lightweight and easy to handle, making them convenient for medical professionals to use. Secondly, plastic tubes are flexible, allowing for easier insertion and maneuverability within the body. Additionally, plastic tubes are transparent, enabling healthcare providers to visually monitor fluids and ensure proper functioning. Plastic tubes are also cost-effective compared to other materials, making them more accessible for medical facilities. Lastly, plastic tubes are generally disposable, reducing the risk of contamination and infection transmission.

- Q:Can plastic tubes be customized in terms of color and size?

- Yes, plastic tubes can be customized in terms of color and size. Manufacturers offer a wide range of color options and can produce tubes in various sizes to meet the specific requirements of customers.

- Q:Where to find inexpensive tubes or plastic vials to fill with candy for a centerpiece?

- You could also buy a roll of tubing at Home Depot or Lowes. It comes in many different diameters, so you should be able to find just what you're looking for! Look in the plumbing aisle.

- Q:Has anyone tried to get inside those plastic balloons that come in the tubes?

- surrrrre wtf are you talking about?

- Q:How do plastic tubes perform in high-temperature environments?

- Plastic tubes may not perform well in high-temperature environments as they have lower heat resistance compared to other materials such as metal.

- Q:I'm conducting a research project and I need a long plastic tube about 20 to 30 feet long with a diameter of 10 or more inches. Approximately how much will I have to pay?

- Here okorder /

- Q:Can plastic tubes be used for greenhouse installations?

- Yes, plastic tubes can be used for greenhouse installations. Plastic tubes are often used to create a framework for greenhouse structures due to their durability, flexibility, and cost-effectiveness. They provide a lightweight and easily customizable option for constructing greenhouse frames, allowing for efficient installation and maintenance. Additionally, plastic tubes can be easily shaped and connected to form various greenhouse designs, making them a popular choice for greenhouse installations.

- Q:How do you clean clogged plastic tubes?

- To clean clogged plastic tubes, you can try a few methods. Start by removing any visible debris or buildup by using a soft brush or cloth. Next, you can try using a mixture of warm water and dish soap to flush out the clog. If the clog persists, you can use a plunger to create pressure and dislodge the obstruction. In more stubborn cases, a combination of baking soda and vinegar can help break down the clog. If none of these methods work, it might be necessary to use a plumbing snake or seek professional help to resolve the issue.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Pipes and Fittings with Manufacturer Professional Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords