Ppr Pipe Fittings Female Threaded Tee from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1.It is used in industrial fields,agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Specifications

Standard:DIN8077/8078

Material:R200P from Korea

Size:DN20-63

Color:Green,White,Grey,Blue

Packaging&Delivery

Packaging Details:PE bag + carton

Delivery Detail:15 Days

Why Us?

1.We can make any requirements in design,pattern,color and size.

2.We can make customer's logo on the surface of products.

3.The dimension tolerance of our products is controlled within 0.03mm.

4.Our products are child safety,pet safety and environment-friendly.

5.Our products are exported to America,Europe,India,west Asia,etc.,and conforms to the standard test.

Product Description

Normal Sizes for CNBM PPR Pipe | ||||||

Outside Diameter(mm) | Wall Thickness(mm) | Package(m/bale) | ||||

S5 PN1.25MPa | S4 PN1.6MPa | S3.2 PN2.0MPa | S2.5 PN2.5MPa | |||

20 | 2 | 2.3 | 2.8 | 3.4 | 120 | |

25 | 2.3 | 2.8 | 3.5 | 4.2 | 120 | |

32 | 2.9 | 3.6 | 4.4 | 5.4 | 80 | |

40 | 3.7 | 4.5 | 5.5 | 6.7 | 60 | |

50 | 4.6 | 5.6 | 6.9 | 8.3 | 40 | |

63 | 5.8 | 7.1 | 8.6 | 10.5 | 24 | |

75 | 6.8 | 8.4 | 10.1 | 12.5 | 16 | |

90 | 8.2 | 10.1 | 12.3 | 15 | 8 | |

110 | 10 | 12.3 | 15.1 | 18.3 | 8 | |

160 | 14.6 | 17.9 | 21.9 | 26.6 | 4 | |

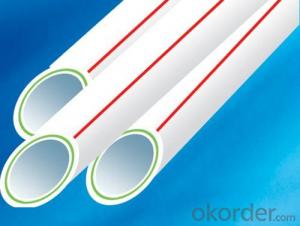

Product Show

- Q:What are the manufacturing processes of plastic pipe fittings?

- 1. switch on the power supply, open the main machine, the co extrusion machine, set the process temperature, open the temperature control host, and then the extruder will riseWarm, turn on the charging machine, dryer.2., the production of pipe specifications, installation of fixed diameter sets, stereotypes spray flange, gasket and so on.3. according to the specification of pipe cutting machine, installed half block, adjust the feed position.

- Q:How do plastic pipe fittings handle high-velocity water flow?

- Plastic pipe fittings are designed to handle high-velocity water flow efficiently. They are typically made from durable materials such as PVC or CPVC, which have excellent resistance to pressure and flow. These fittings are engineered to provide a secure and tight connection, ensuring that they can withstand the force of high-velocity water without leaking or failing. Additionally, plastic fittings are corrosion-resistant, making them suitable for long-term use in high-velocity water flow applications.

- Q:Are plastic pipe fittings suitable for mining operations?

- Yes, plastic pipe fittings can be suitable for mining operations. Plastic pipe fittings offer several advantages such as corrosion resistance, lightweight construction, and ease of installation. Additionally, plastic pipe fittings can withstand high pressures and are durable, making them suitable for various mining applications. However, the specific requirements and conditions of each mining operation should be considered to ensure proper selection and installation of plastic pipe fittings.

- Q:What quota should plastic tube be fitted?

- The installation of fixed base according to their own actual situation to apply, pay attention to the installation quota, no material cost

- Q:How do you prevent leaks in plastic pipe fittings?

- To prevent leaks in plastic pipe fittings, it is essential to follow a few key steps. Firstly, ensure that the pipe ends are clean and free from any dirt or debris. Next, use proper tools to tighten the fittings securely, avoiding over-tightening which may damage the threads. Applying a suitable sealant or thread tape to the male threads can also help create a watertight seal. Finally, regularly inspect the fittings for any signs of wear or damage, and promptly replace any faulty components to prevent leaks from occurring.

- Q:Can plastic pipe fittings be used in fire detection systems?

- No, plastic pipe fittings cannot be used in fire detection systems as they do not have the necessary fire resistance properties required for such critical safety systems.

- Q:What are the potential drawbacks of using plastic pipe fittings?

- One potential drawback of using plastic pipe fittings is their susceptibility to degradation over time, especially when exposed to UV rays or chemicals. This can lead to cracking, leaks, or even total failure of the fittings. Additionally, plastic fittings may have lower heat resistance compared to other materials, which can limit their use in high-temperature applications. Furthermore, plastic fittings may not be as durable as metal fittings, making them more prone to breakage or damage during installation or maintenance. Lastly, plastic pipe fittings may not be suitable for certain types of plumbing systems or environments, such as those with high pressure or corrosive substances, where stronger materials like metal may be more appropriate.

- Q:What are the different types of plastic pipe fittings?

- The different types of plastic pipe fittings include couplings, elbows, tees, reducers, adapters, unions, caps, plugs, and valves.

- Q:Are plastic pipe fittings resistant to rodent damage?

- Yes, plastic pipe fittings are generally resistant to rodent damage. Unlike materials like wood or rubber, plastic is not attractive to rodents for gnawing or chewing. Therefore, plastic pipe fittings are less likely to be damaged or compromised by rodents.

- Q:How do plastic pipe fittings compare to brass fittings?

- Plastic pipe fittings are generally more affordable and easier to install compared to brass fittings. However, brass fittings are known for their durability, strength, and resistance to high temperatures and pressure. They are also less likely to leak or crack over time. Ultimately, the choice between plastic and brass fittings depends on the specific needs and requirements of the plumbing system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ppr Pipe Fittings Female Threaded Tee from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords