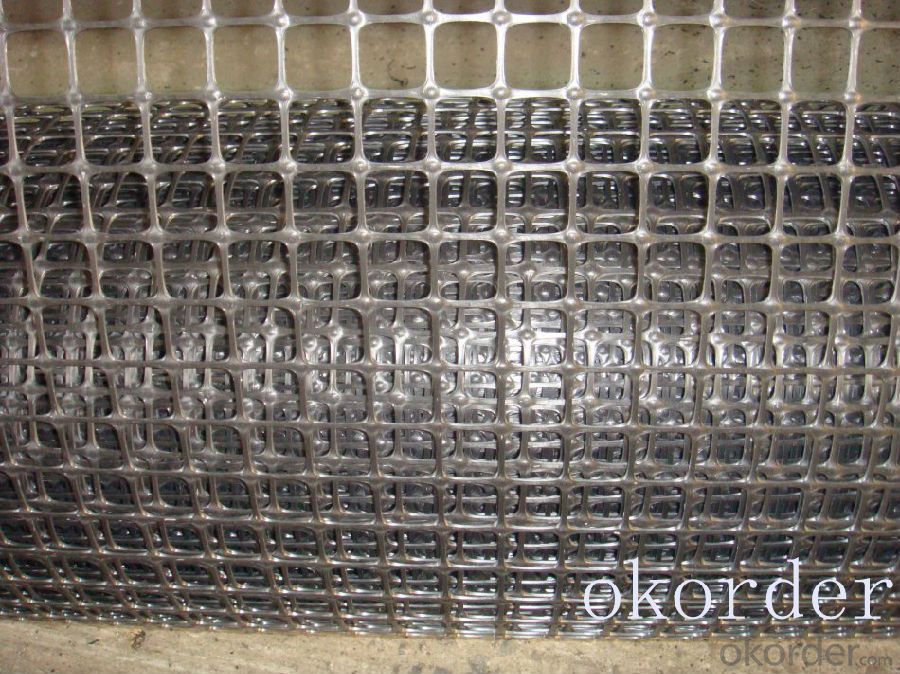

Steel Plastic Geogrids of Civil Engineering Products in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

color:

black

certification:

ISO9001,ISO14001

standard:

GB/T 17639-2008

MOQ:

5000m2

Place of origin:

Shandong,China

packing:

according to customer's need

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Do geogrids enhance the load-bearing capacity of soil?

- Yes, geogrids can enhance the load-bearing capacity of soil. Geogrids are typically made of high-strength materials and are used to reinforce soil by providing additional tensile strength. When placed within the soil, geogrids distribute the load more evenly, reducing the potential for soil failure and increasing the load-bearing capacity of the soil.

- Q:Can geogrids be used in temporary construction haul roads?

- Yes, geogrids can be used in temporary construction haul roads. Geogrids are commonly used to reinforce and stabilize the soil, providing additional strength and load-bearing capacity. They can effectively distribute the load from construction vehicles, reduce rutting, and increase the lifespan of temporary roads.

- Q:Can geogrids be used in ground stabilization for water treatment plants?

- Yes, geogrids can be used effectively in ground stabilization for water treatment plants. Geogrids are a type of geosynthetic material that provide reinforcement and stability to soils, making them ideal for preventing soil erosion and improving the load-bearing capacity of the ground. By using geogrids, water treatment plants can ensure the stability and longevity of their infrastructure, preventing soil settlement and potential damage caused by heavy equipment and machinery. Additionally, geogrids can help control soil erosion and maintain the integrity of slopes or embankments surrounding the water treatment plant, further enhancing its overall stability.

- Q:Are geogrids suitable for reinforcement of mechanically stabilized aggregate base layers?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized aggregate base layers. Geogrids are designed to improve the strength and stability of soil or aggregate layers by distributing loads more efficiently and reducing lateral movement. They can enhance the performance and lifespan of mechanically stabilized aggregate base layers by increasing their load-bearing capacity, reducing rutting, and preventing the formation of cracks.

- Q:Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method

- Peel out because of the more intuitive understanding of the strength of the tensile strength and extension of the length of the wire wrapped in order to protect the steel wire does not rust.

- Q:What is the recommended geogrid connection method for specific applications?

- The recommended geogrid connection method for specific applications depends on factors such as the type of soil, slope angle, and expected load conditions. Some common geogrid connection methods include mechanical connectors, welded connections, and soil wrap-around techniques. It is important to consult with a geotechnical engineer or follow manufacturer's recommendations to determine the most suitable connection method for a specific application.

- Q:How do geogrids improve the performance of retaining walls in earthquake-prone areas?

- Geogrids improve the performance of retaining walls in earthquake-prone areas by providing reinforcement and stability. These high-strength geosynthetic materials are placed within the soil behind the retaining wall, which helps to distribute the forces generated during an earthquake more evenly. This reduces the pressure on the wall and enhances its resistance to lateral movement and potential failure. Geogrids also increase the overall strength and load-bearing capacity of the soil, making the retaining wall more resilient against seismic forces.

- Q:What are the potential drawbacks of using geogrids?

- One potential drawback of using geogrids is their high initial cost compared to traditional construction materials. Additionally, geogrids require skilled installation and may have limited availability in certain regions. There is also a risk of improper installation or maintenance, which can lead to reduced effectiveness or failure of the geogrids. Moreover, the long-term durability of geogrids is still being studied, and their performance can be influenced by factors such as UV radiation and chemical exposure.

- Q:What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one direction, typically along the longitudinal axis, while biaxial geogrids have strength and stiffness in both the longitudinal and transverse directions.

- Q:Can geogrids be used in reinforcement of soil-nailing systems?

- Yes, geogrids can be used in reinforcement of soil-nailing systems. Geogrids are commonly used in soil reinforcement applications, including soil-nailing systems, to provide additional stability and strength to the soil. They are typically installed behind the soil nails to distribute the loads and prevent soil movement, enhancing the overall performance of the system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Plastic Geogrids of Civil Engineering Products in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords