Good Toughness Polyethylene Geogrid High strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

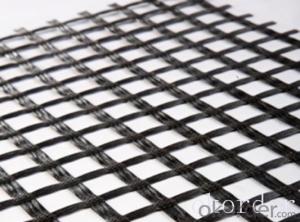

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Geogrids form a distinct category of geosynthetics designed for reinforcement.

Fiberglass Geogrid with CE Certificate

We can produce fiberglass geogrid with tensile strength 30x30kn--300x300kn/m. mesh size can be 25.4x25.4mm or 12.7x12.7m ,50x50mm.

Type:

Geogrids

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geogrids be used in retaining walls for industrial facilities?

- Yes, geogrids can be used in retaining walls for industrial facilities. Geogrids are commonly used in retaining walls to increase their stability by providing soil reinforcement. They help distribute the forces exerted by the retained soil, making them suitable for use in retaining walls for industrial facilities where there may be higher loads and potentially unstable soil conditions.

- Q:Do geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers?

- Yes, geogrids do provide reinforcement to geosynthetic asphalt liners in landfill covers.

- Q:What are the advantages of using geogrids in ground reinforcement?

- There are several advantages to using geogrids in ground reinforcement. Firstly, geogrids provide increased stability and load-bearing capacity to the soil, making them beneficial for areas with weak or unstable ground. Secondly, they help prevent soil erosion, as the geogrids act as a barrier that holds the soil in place. Additionally, geogrids can reduce construction costs by allowing for the use of locally available, less expensive fill materials. They also facilitate faster construction times, as they are easy to install and require minimal excavation. Overall, geogrids offer a cost-effective and efficient solution for ground reinforcement projects.

- Q:Do geogrids provide reinforcement to geosynthetic asphalt liners in reservoirs?

- No, geogrids do not provide reinforcement to geosynthetic asphalt liners in reservoirs.

- Q:Are geogrids resistant to chemical attack from soil contaminants?

- Yes, geogrids are generally resistant to chemical attack from soil contaminants.

- Q:Can geogrids be used in retaining wall drainage systems?

- Yes, geogrids can be used in retaining wall drainage systems. Geogrids are commonly used to reinforce soil and provide stability to retaining walls. They can also be employed as part of a drainage system to help manage water pressure and prevent the accumulation of excess water behind the wall. By allowing for efficient drainage, geogrids can enhance the overall performance and longevity of retaining walls.

- Q:The price of the type of geogrid manufacturers is the best phone

- No long-term creep as reinforcing material, have in long-term load under the condition of deformation resistance that the creep resistance is extremely important, glass fiber does not creep, which ensure product can maintain long-term performance.

- Q:Are geogrids suitable for use in railway ballast reinforcement?

- Yes, geogrids are suitable for use in railway ballast reinforcement. Geogrids are designed to provide structural support and increase the stability of railway ballast. They help distribute loads and prevent lateral movement of the ballast, enhancing the overall performance and longevity of the railway track.

- Q:What is the effect of installation spacing on geogrid behavior?

- The effect of installation spacing on geogrid behavior is that it can impact the overall performance and effectiveness of the geogrid. Proper installation spacing ensures proper load distribution and reinforcement, allowing the geogrid to effectively stabilize the soil and prevent deformation or failure. Inadequate spacing can lead to localized stress concentrations, reduced load capacity, and potential geogrid failure. Therefore, the spacing between geogrid installations is an important factor to consider in order to achieve optimal performance and long-term stability.

- Q:What are the design considerations for geogrid installation?

- Some of the key design considerations for geogrid installation include selecting the appropriate type and strength of geogrid material based on the specific application and soil conditions, determining the correct spacing and orientation of the geogrid layers, ensuring proper soil compaction and preparation before installation, and considering factors such as slope stability, load bearing capacity, and drainage requirements. Additionally, proper anchoring and connection techniques, as well as proper quality control and monitoring during installation, are essential for a successful geogrid installation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Toughness Polyethylene Geogrid High strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords