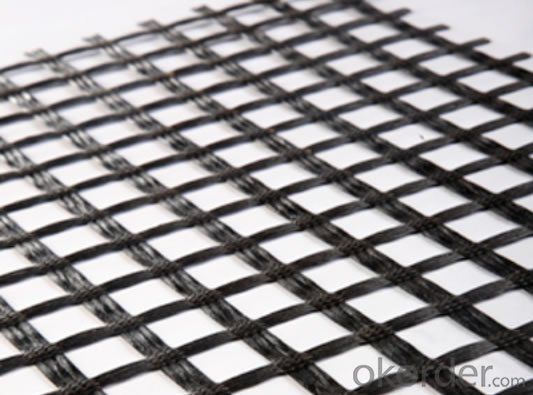

High Strength Fiberglass Geogrid in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact polyethylene and polypropylene. Geogrids are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

1)fiberglass geogrid with CE certificate

2)Materials:fiberglass

3) Tensile strength:MD/CD:30 ~ 200kn/m

4)WIdth:1 ~ 6m

Material Major Advantages

Geogrid application is a way of soil reinforcement, On soil surface a plate is created according to the thickness of a corresponding geogrid: 50 mm, 100 mm, 150 mm, 200 mm (this standard range of products is manufactured by “Technostroytex” LLC).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What is the coefficient of friction of Nonwoven Geotextiles (polypropylene)?

- The biggest difference is that the geotextile with the membrane is impermeable and the nonwoven geotextile is permeable

- Q:How do geogrids enhance the load-bearing capacity of pavements?

- Geogrids enhance the load-bearing capacity of pavements by providing reinforcement and improving the overall stability of the pavement structure. They act as a support system, distributing and transferring loads more evenly across the pavement surface, which reduces the risk of cracking, rutting, and other types of pavement distress. Geogrids also help to prevent lateral movement and improve the confinement of granular materials, thereby increasing the pavement's resistance to deformation and extending its lifespan.

- Q:What is the difference between geotextiles and geogrids?

- The geotextile is used to prevent seepage and the geogrid is used to reinforce

- Q:What is the tensile strength of geogrids?

- The tensile strength of geogrids can vary depending on the specific type and manufacturer, but it is typically measured in the range of several hundred to several thousand pounds per foot.

- Q:What are the limitations of using geogrids?

- There are several limitations associated with using geogrids. Firstly, geogrids may not be suitable for all types of soil conditions. They are most effective in granular soils but may not provide the same level of reinforcement in cohesive or heavily saturated soils. Additionally, geogrids are not effective in addressing settlement issues or soil instability caused by organic or highly compressible soils. Furthermore, installation of geogrids can be labor-intensive and time-consuming, requiring specialized equipment and expertise. The cost of purchasing and installing geogrids can also be relatively high compared to other soil stabilization methods. Another limitation is that geogrids have a limited design life, typically ranging from 20 to 50 years. Over time, they may degrade due to environmental factors such as UV exposure, temperature variations, and chemical reactions. This degradation can reduce their effectiveness and require maintenance or replacement. Lastly, the long-term performance of geogrids can be affected by factors such as differential settlement, inadequate compaction, and improper installation. Without proper inspection and quality control measures, geogrids may not provide the expected level of reinforcement or stability. Overall, while geogrids offer numerous benefits in soil reinforcement and stabilization, their limitations should be carefully considered and evaluated before deciding on their use in a particular project.

- Q:Are geogrids effective in preventing soil erosion on coastal cliffs?

- Yes, geogrids are effective in preventing soil erosion on coastal cliffs. These engineered materials provide reinforcement and stabilization to the soil, preventing it from being washed or blown away by wind or water. They help to distribute the forces applied to the soil, reducing the risk of erosion and slope failure. Additionally, geogrids can promote vegetation growth, further enhancing their effectiveness in preventing soil erosion on coastal cliffs.

- Q:What is the market price of the geotechnical grid in 2017?

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.

- Q:Are geogrids suitable for use in reinforced steep slopes?

- Yes, geogrids are suitable for use in reinforced steep slopes. Geogrids are engineered materials that provide soil stabilization and reinforcement, making them effective in preventing erosion and maintaining the stability of steep slopes. They enhance the integrity of the soil structure and distribute the load evenly, reducing the risk of slope failure. Geogrids have been extensively used in various applications, including reinforced steep slopes, due to their high tensile strength, durability, and ability to withstand extreme forces.

- Q:Light material, wear resistance, chemical stability, light oxygen aging, acid and alkali resistance, suitable for different soil and desert soil conditions.

- EM2 for the 2 layer, there are also EM3.EM4......

- Q:What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of the geogrid material used can significantly impact the overall cost. Higher-quality geogrids may initially be more expensive but offer better long-term performance, potentially reducing maintenance and repair costs over time. Additionally, the design and engineering of the structure play a crucial role. Properly designed geogrid-reinforced structures can optimize material usage and minimize construction costs. The expertise and experience of the engineers and contractors involved also contribute to the cost-effectiveness, as their knowledge can help avoid unnecessary expenses and ensure efficient construction. The specific site conditions, such as soil characteristics and slope stability, are also important factors. Geogrids are typically used to enhance soil stability, so the suitability of the soil for reinforcement and the extent of reinforcement required can impact costs. Difficult terrain, challenging access, or the need for additional site preparation can also increase costs. Lastly, the lifespan and durability of geogrid-reinforced structures should be considered. While geogrids are designed to be long-lasting, factors like environmental conditions, loading requirements, and proper installation can affect their performance. Investing in high-quality materials and proper installation methods may initially increase costs but can result in longer service life and reduced maintenance expenses in the long run.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Fiberglass Geogrid in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords